Centralized-transmitting roller-type sieving machine with adjustable gaps among sieve rollers

A technology of centralized transmission and screening machine, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of motor reducer occupying space, affecting the production of green pellets, and high failure rate of equipment, so as to reduce the cost of equipment replacement parts and maintenance The number of times, the gap between the screen rollers is convenient and adjustable, and the equipment structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

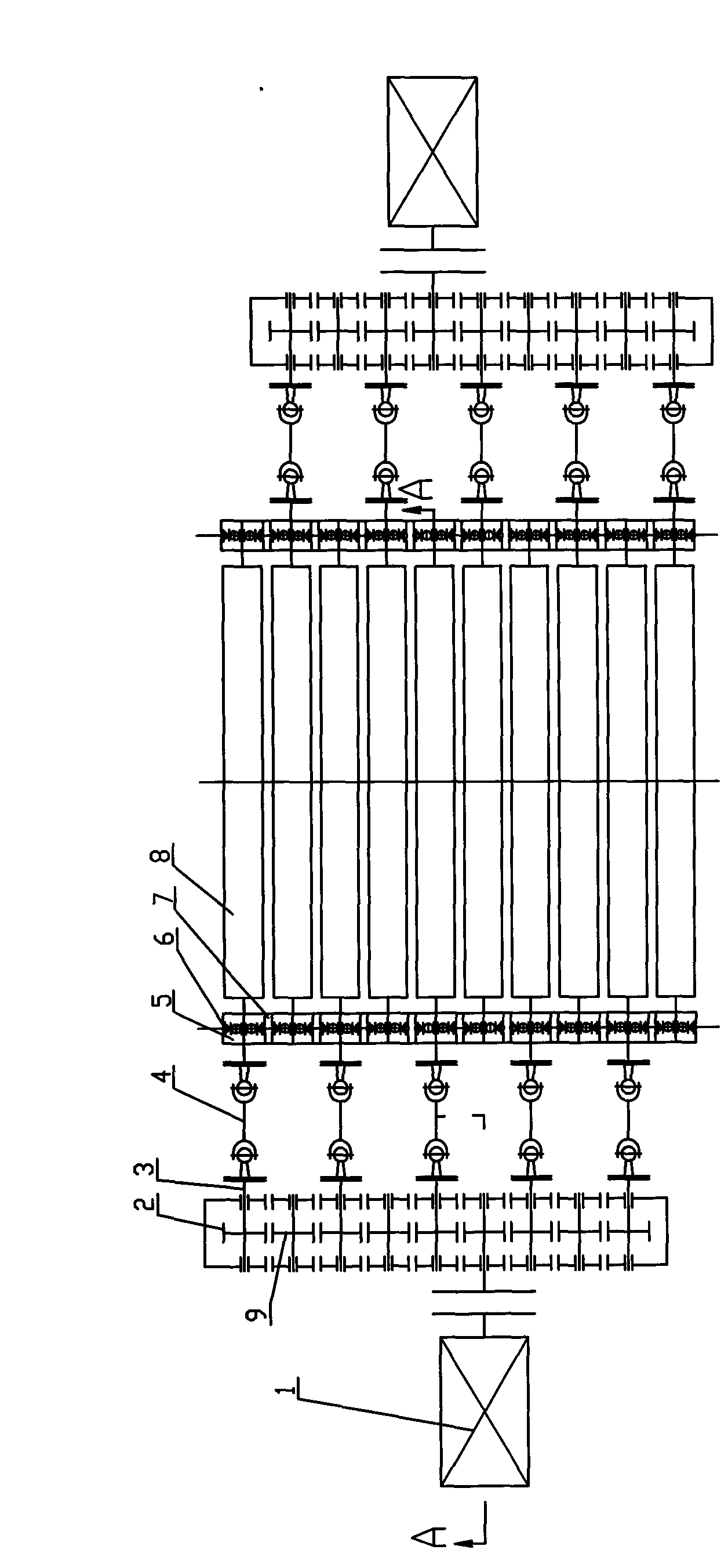

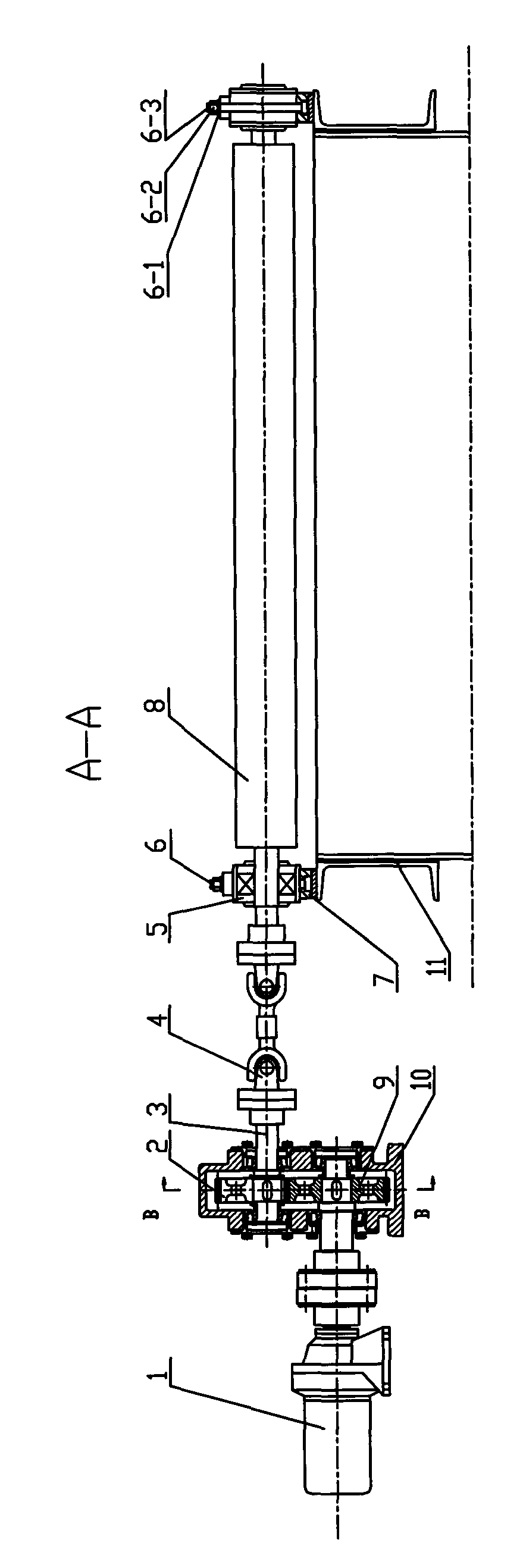

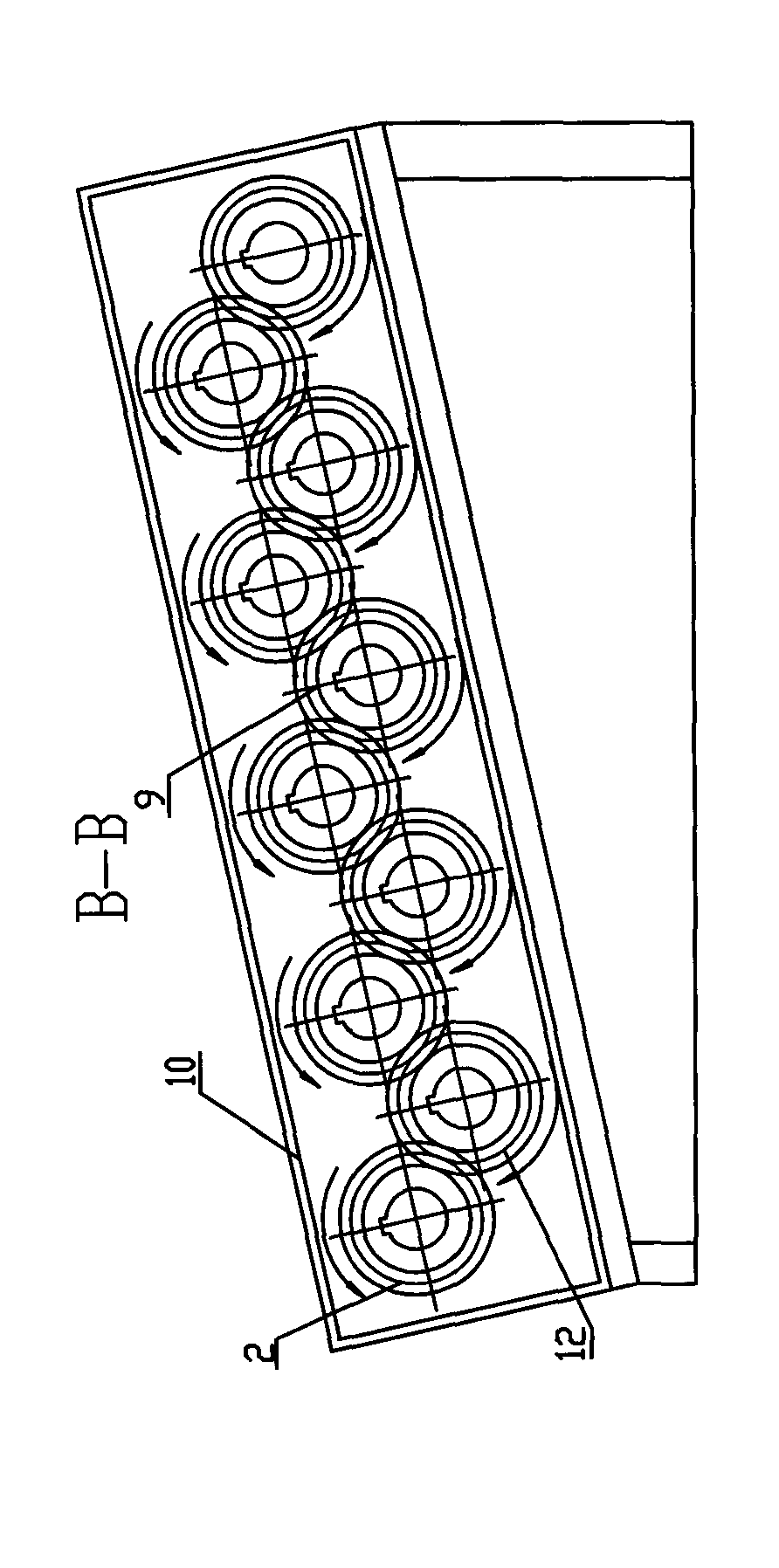

[0013] Such as figure 1 , 2 , Shown in 3, a kind of roll type screening machine of the present invention with adjustable clearance between transmission screen rollers, comprises gear box 10, motor reducer 1, the drive gear 9 that is connected with this motor reducer 1, and this drive gear 9 A group of transmission gears 2 with an output shaft 3 meshingly connected, a group of intermediate gears 12 meshed with this group of transmission gears 2, a group of screen rollers 8, bearing blocks 5 and Screen roller tilt bracket 11 is characterized in that: each of the output shafts 3 is connected to one end of a universal coupling 4, and the other end of the universal coupling 4 is connected to a screen roller 8, and each Both ends of each screen roller 8 are provided with bearing housings 5 with bearings, and each bearing housing 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com