Full automatic punching machine integrating punching and counterboring

A punching machine, fully automatic technology, applied in the direction of piercing tools, forming tools, feeding devices, etc., can solve the problems of high labor intensity, poor quality, unsafe operation, etc., and achieve safe processing, high production efficiency, and strong functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

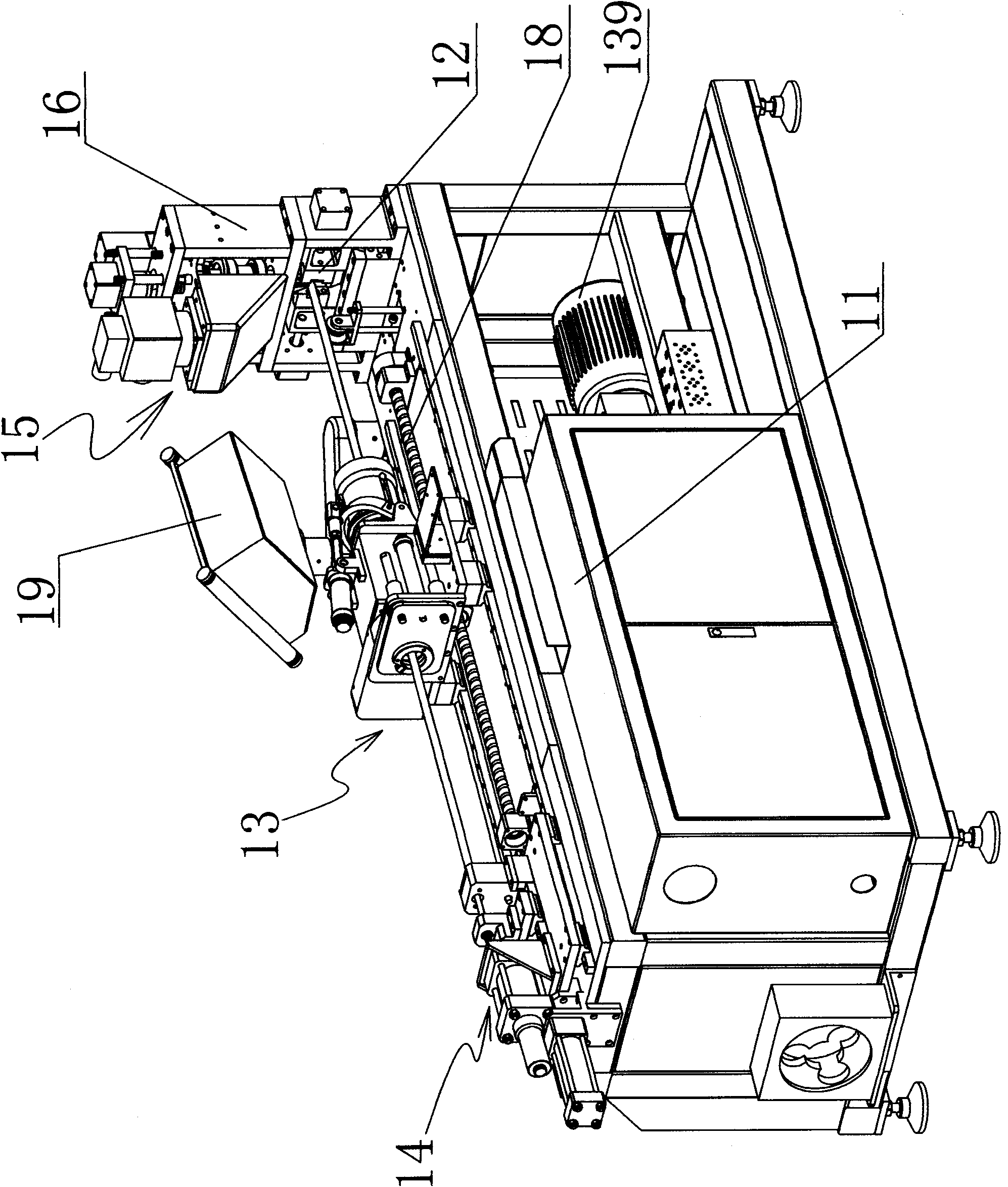

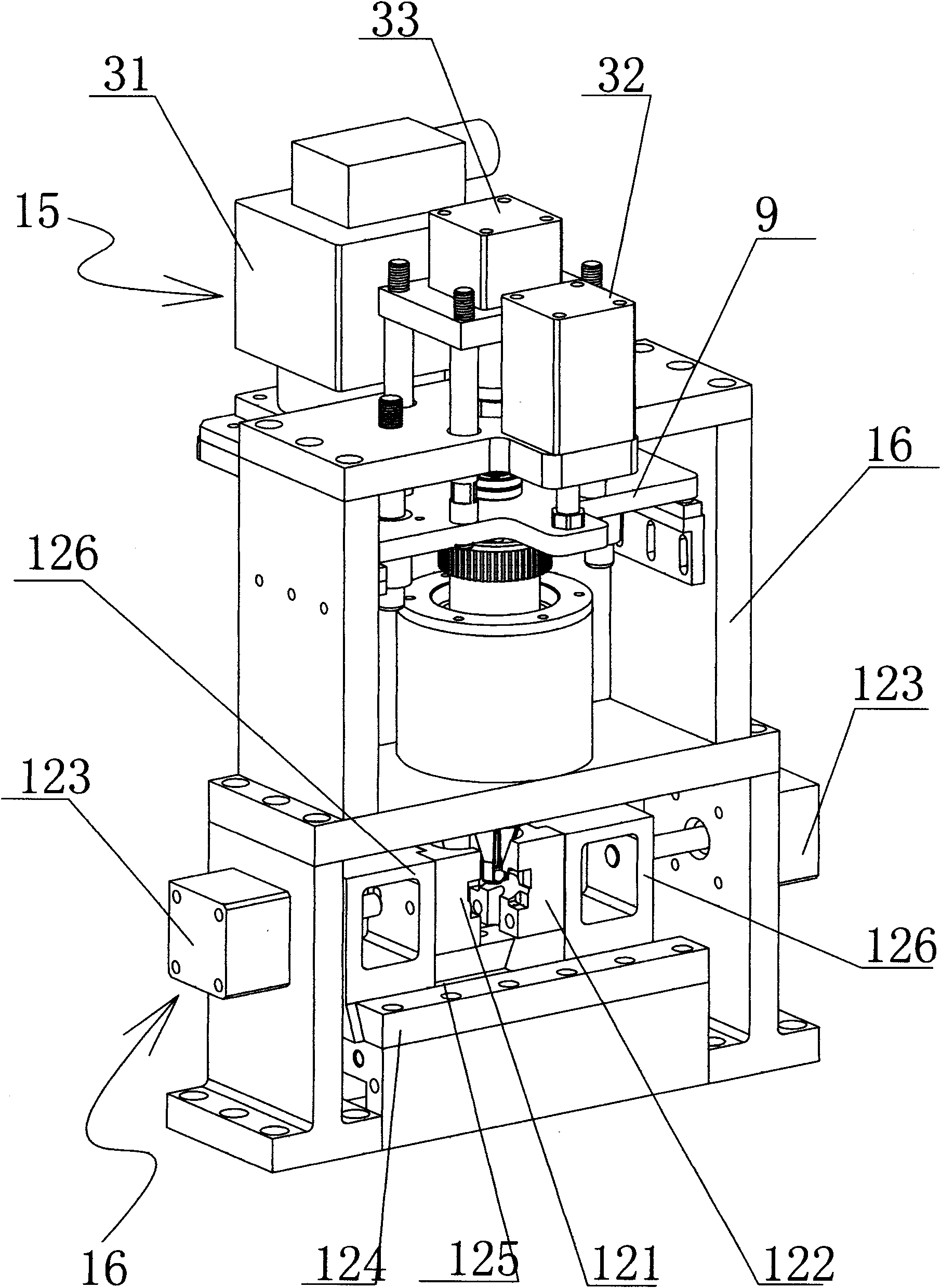

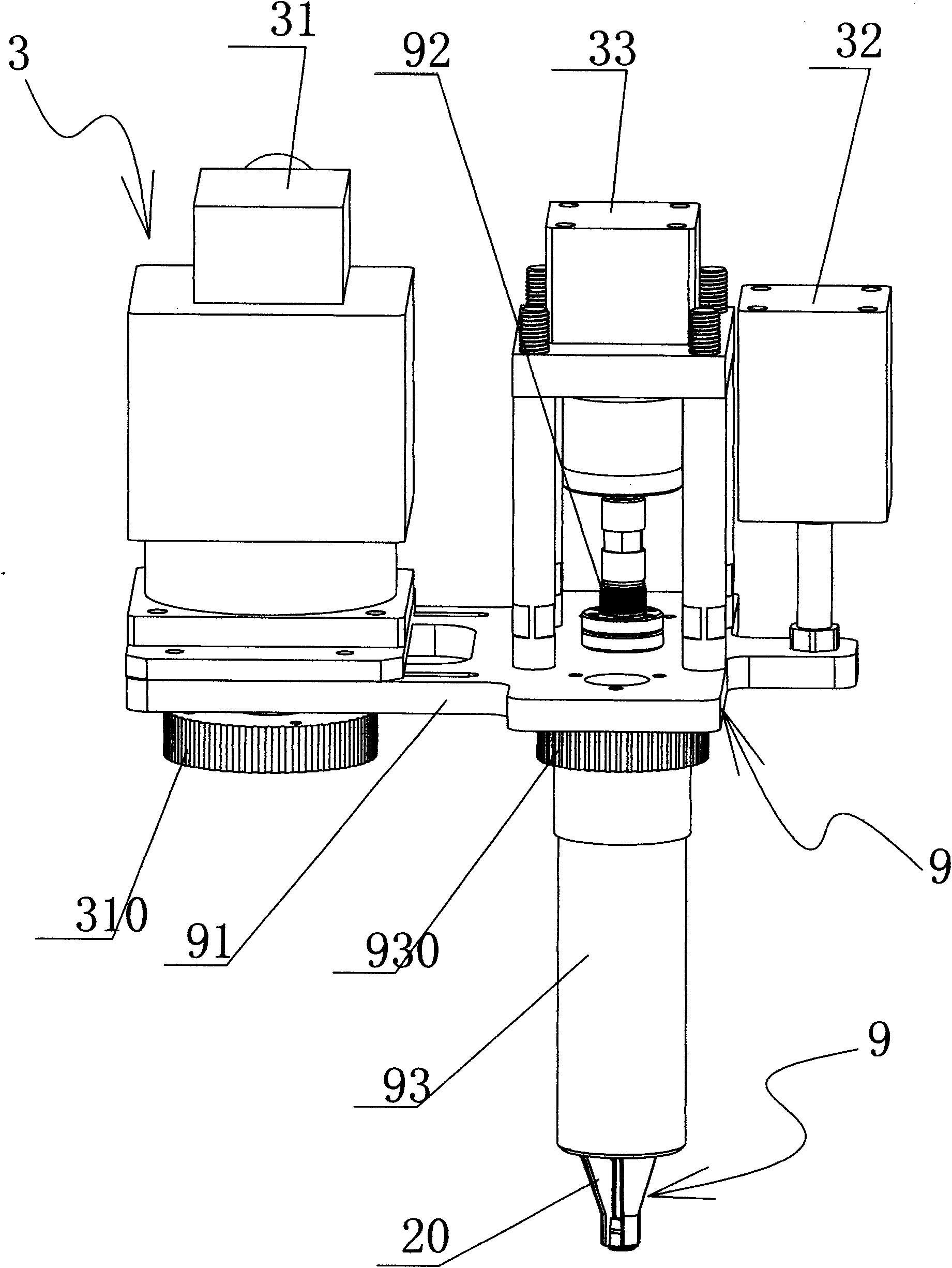

[0037] As shown in the figure, the fully automatic punching machine that integrates punching and reaming includes a frame 11, on which a clamping die assembly 12, a feeding mechanism 13 that can reciprocate along the X axis, and An automatic punching device 14 , an automatic hole reaming device 15 is arranged above the clamping die assembly 12 . The automatic hole reaming device 15 is installed on a fixed frame 16, and the clamping mold assembly 12 is located directly below the fixed frame 16. The clamping mold assembly 12 includes a left clamping mold 121, a right clamping mold 122 and a driving left clamping mold for clamping pipe fittings. Die 121, two oil cylinders 123 that the right clamping die 122 moves. Wherein, the left clamping die 121, the right clamping die 122 are installed with mold base 124, and the mold base 124 is provided with chute 125, and the activity card in the chute 125 is equipped with two movable die holders 126, and left clamping die 121 and right C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com