Clean multi-fuel internal combustion engine

An internal combustion engine, multi-fuel technology, applied to internal combustion piston engines, adding non-fuel substances to fuel, combustion engines, etc., can solve the problems of high carbon monoxide emissions, low thermal efficiency of gasoline engines, and increased fuel consumption, reducing harmful gas emissions and improving thermal efficiency. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

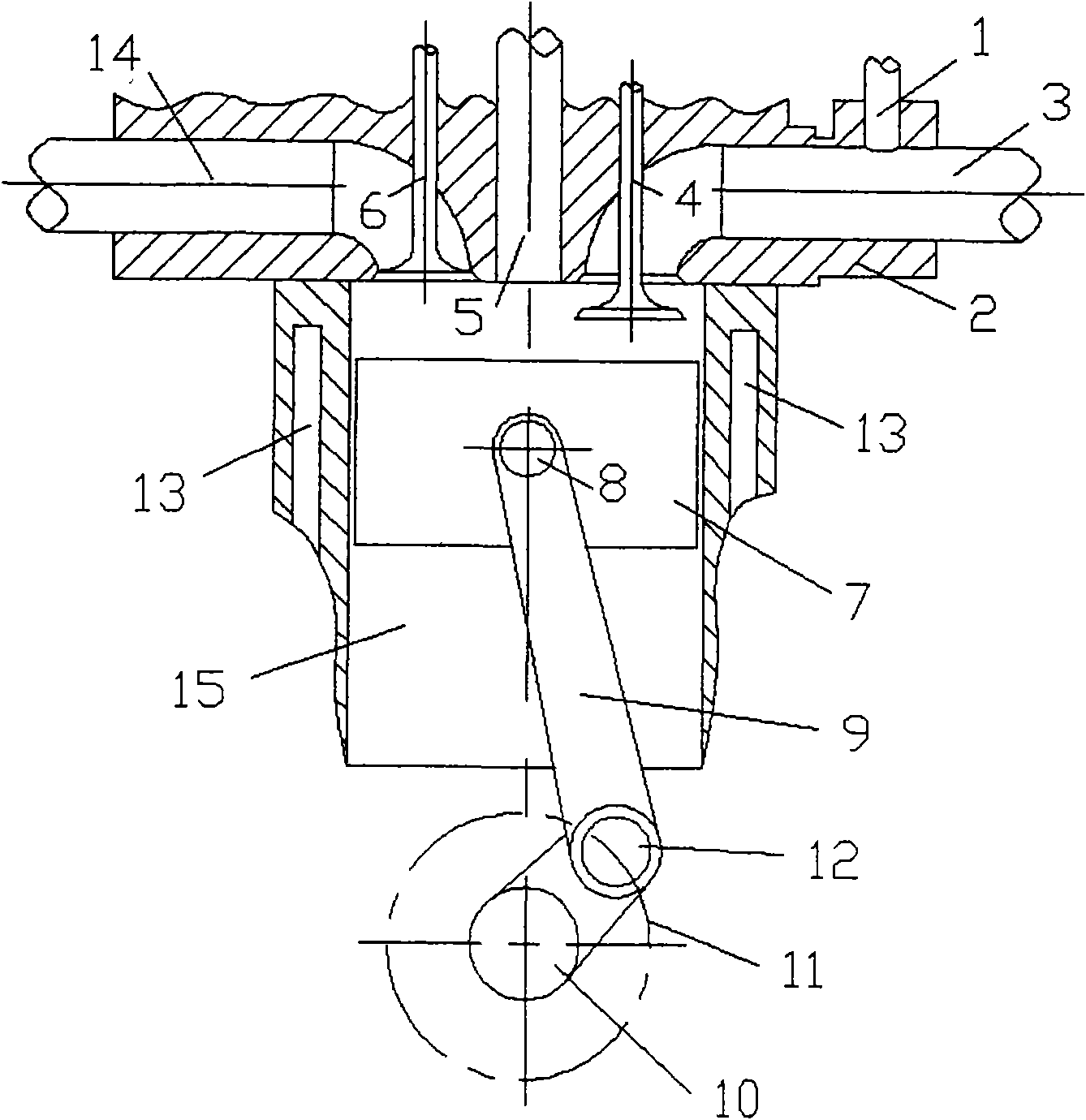

[0009] The clean multi-fuel internal combustion engine proposed by the present invention has a structure such as figure 1 As shown, it includes cylinder 15, piston 7, connecting rod 9, crankshaft 10, intake port 3, intake valve 4, exhaust port 14, exhaust valve 6, fuel injector or igniter 5, and injector 1 . The piston 7 is placed in the cylinder 15, one end of the connecting rod 9 is connected with the piston 7 through the piston pin 8, and the other end of the connecting rod 9 is linked with the crankshaft 10 through the crankpin 12 and the crank 2. The intake port 3, the exhaust port 14 and the fuel injector or igniter 5 are placed on the top of the cylinder, the intake port 3 is connected to the cylinder 15 through the intake valve 4, and the exhaust port 14 is connected to the cylinder 15 through the exhaust valve 6 Through, the fuel injector or igniter 5 is placed on the top of the cylinder 15 and communicated with the cylinder. The injector 1 is placed on the side wal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap