Diaphragm type PCV valve

A diaphragm type and diaphragm technology, which is applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve the problems of not being able to close normally, prone to abnormal noise, poor valve seating, etc., to achieve the effect of reducing abnormal noise and prolonging the service life

Active Publication Date: 2011-01-05

CHERY AUTOMOBILE CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem of the blow-by of the piston in the crankcase, the engine must be equipped with a PCV valve connecting the crankcase and the intake manifold. Most of the existing PCV valves use diaphragm PCV valves, which have a large flow area. Only one ventilation line is needed to introduce the piston blow-by gas in the crankcase into the intake system in time, but because the PCV valve is closed when the engine is idling, and the engine still has a certain amount of piston blow-by gas at this time, when When the air leakage of the piston in the crankcase reaches a certain pressure, the PCV valve will be opened instantaneously. At this time, the air flow passes through the channel with a small cross-section, which is prone to abnormal noise.

In addition, due to the frequent opening and closing of the PCV valve, if the valve is only guided by the spring, it is prone to poor seating or even failure to close normally after a long period of work, resulting in deformation of the diaphragm and spring, and abnormal noise at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

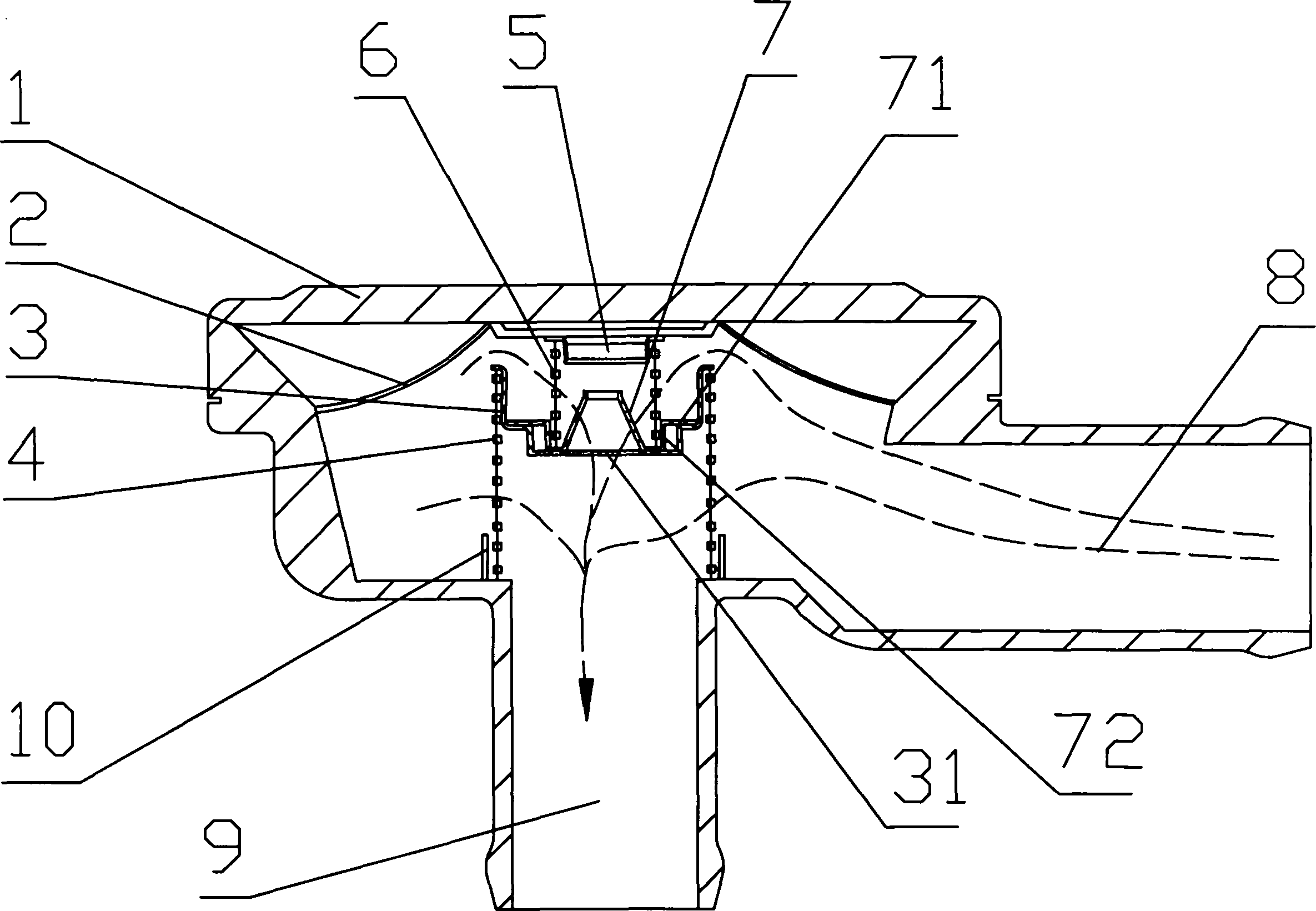

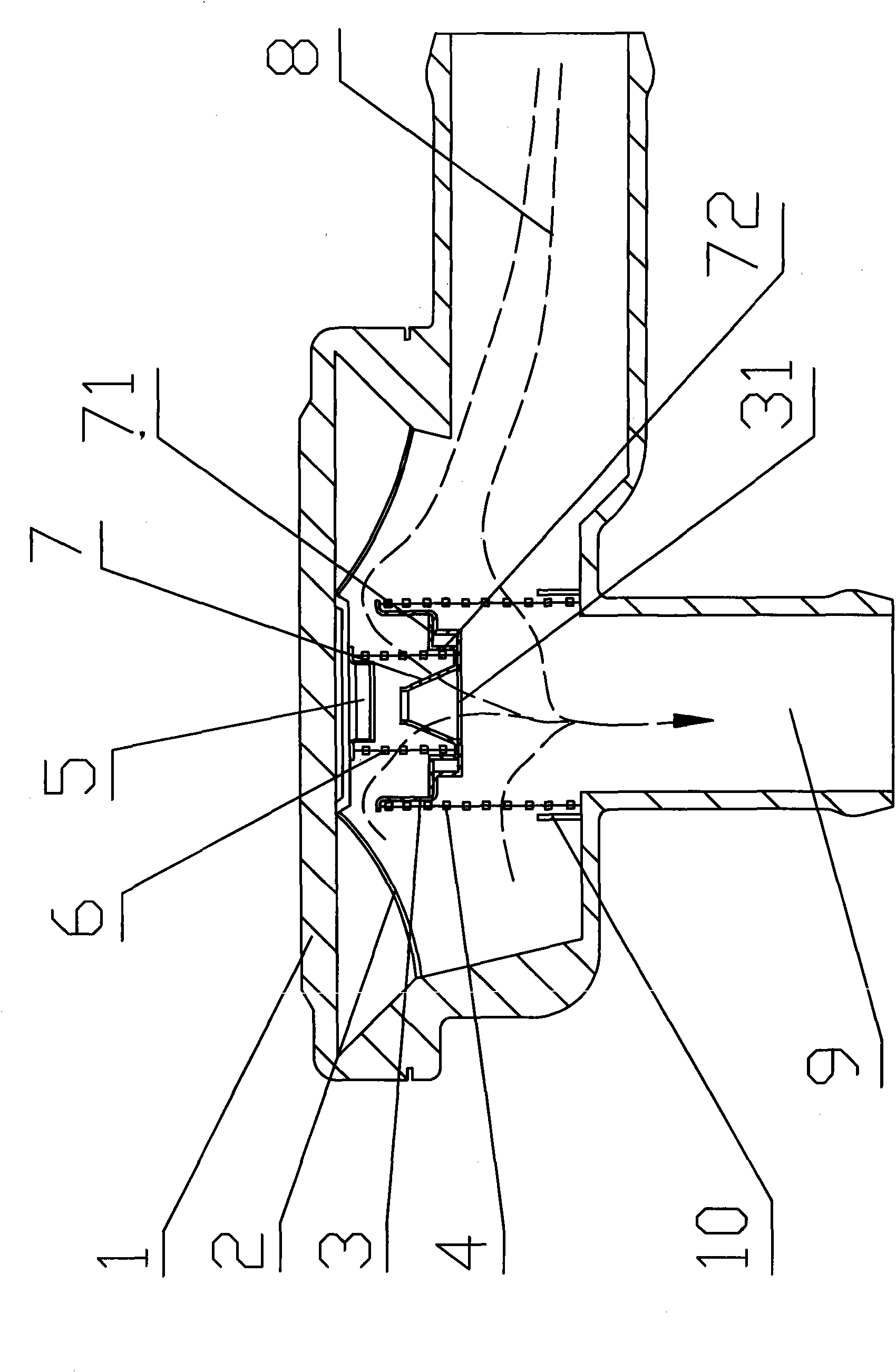

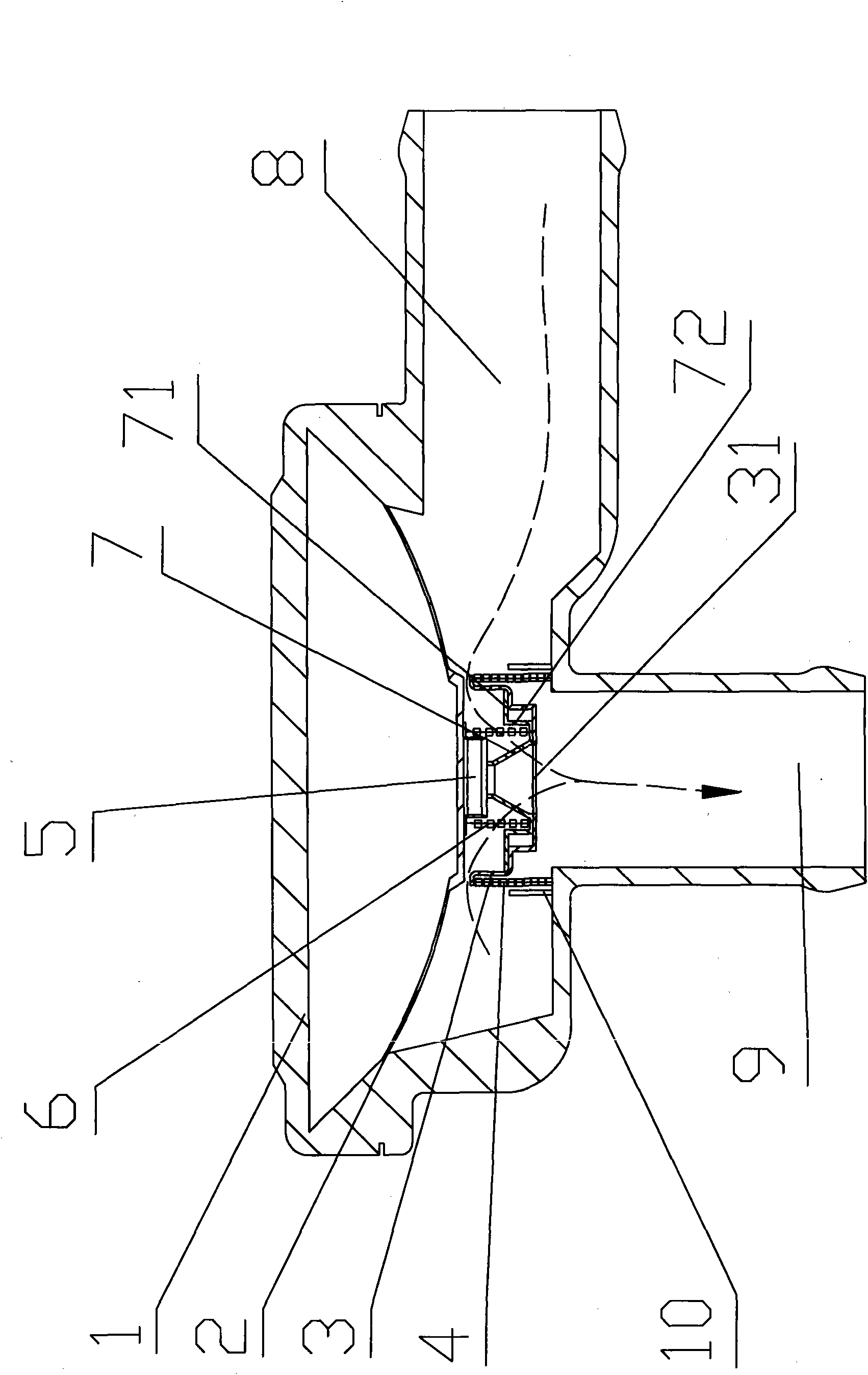

The invention provides a diaphragm type PCV valve which can decrease abnormal sound. The diaphragm type PCV valve comprises a hollow shell and a film in the shell. The shell is provided with an air outlet and an air inlet respectively on the lower part and the lateral part of the film. A big spring is fixed at the air outlet. The top of the big spring is connected with a big spring bracket which is provided with a through hole on the bottom. A supporting block is fixed at the position of the film corresponding to the big spring bracket. A small spring is fixed on the periphery of the supporting block. A small spring bracket is disposed on the bottom of the small spring. The middle part of the small spring protrudes upwards and extends into the small spring. A through hole is arranged on the part of the small spring bracket which is inside of the small spring. With a supporting block and various guiding structures, the PCV valve can fully induct air in a crankcase into an induction system when engine works with a small load and can limit and guide the reciprocating movement of spring to decrease the abnormal sound generated from the diaphragm type PCV valve and prolong the service life of PCV valve.

Description

A Diaphragm PCV Valve technical field The present invention relates to a PCV valve for an engine crankcase ventilation system. Background technique In order to solve the problem of the blow-by of the piston in the crankcase, the engine must be equipped with a PCV valve connecting the crankcase and the intake manifold. Most of the existing PCV valves use diaphragm PCV valves, which have a large flow area. Only one ventilation line is needed to introduce the piston blow-by gas in the crankcase into the intake system in time, but because the PCV valve is closed when the engine is idling, and the engine still has a certain amount of piston blow-by gas at this time, when When the air leakage of the piston in the crankcase reaches a certain pressure, the PCV valve will be opened instantaneously. At this time, the air flow passes through the channel with a small cross-section, which is prone to abnormal noise. In addition, due to the frequent opening and closing of the PCV valve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16K7/17F01M13/00

CPCF01M2013/0016F01M13/0011

Inventor 陈洪方

Owner CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com