Petroleum pipeline detecting system

A detection system and oil pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of unstable running speed of detectors, untimely data information transmission, and low positioning accuracy of pipeline defects. Achieve the effect of reducing missed detection of pipeline defects, realizing timing positioning, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

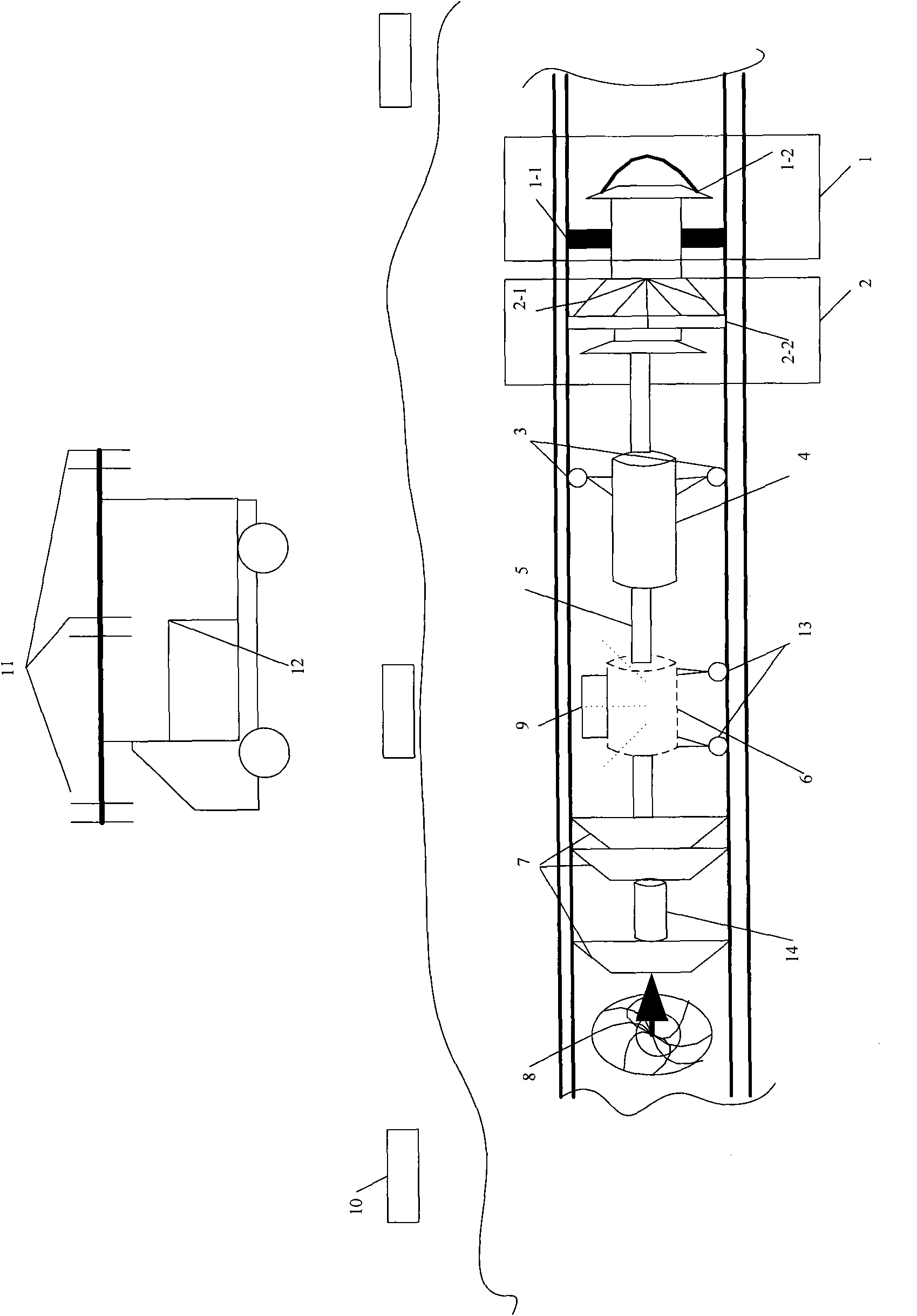

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0025] combine figure 1 , the magnetic flux leakage detector of the present invention differs according to the order of the functions completed by each part in the detection process:

[0026] 1. Driving device 7. The magnetic flux leakage detector moves forward in the tube through the pressure difference generated by the liquid on the surface of the driving cup. Due to the change of the liquid pressure in the tube, the running speed of the detector is unstable and the accuracy of the detection is affected. Therefore, it is necessary to pass the speed The control device 8 changes the size of the driving surface in contact with the liquid, and then changes the driving force to achieve the purpose of adjusting the running speed of the detector. A battery section 14 is installed in the middle of the driving device 7 to provide the energy required for the normal oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com