Carbon fiber lapped type strain sensor

A strain sensor and carbon fiber technology, applied in the sensing field, can solve the problems of poor resistivity stability, easy to be affected by the environment, difficult to make sensors, etc., and achieve the effect of improving stability and sensing sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

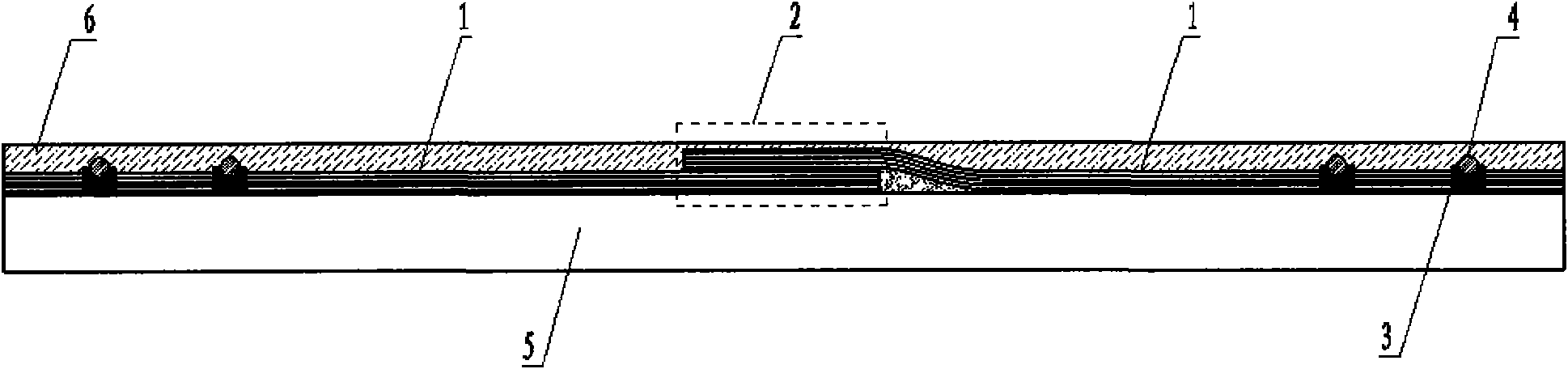

[0032] Such as figure 1 As shown, a carbon fiber lap sensor includes: resin-based fixed-length carbon fiber 1, carbon fiber lap layer 2, conductive adhesive 3, electrode 4, backing plate 5, carbon fiber surface coated with conductive adhesive 3, and conductive adhesive with electrodes 4. The carbon fiber, resin, conductive glue and electrodes are fixed on the backing plate 5 to form a complete carbon fiber lap sensor, and the entire surface of the sensor is coated with a protective layer 6 . Wherein: the resin is epoxy resin or unsaturated resin; the conductive glue is silver glue material; the protective layer is ultraviolet-proof resin material.

[0033] In the carbon fiber lap strain sensor, the resin is used as the matrix and the adhesive, and the continuous carbon fibers with two overlapping ends are molded and solidified on the backing plate; at the end of the carbon fiber that is not overlapped, electrodes are provided through conductive glue, and the entire The sensor...

Embodiment 2

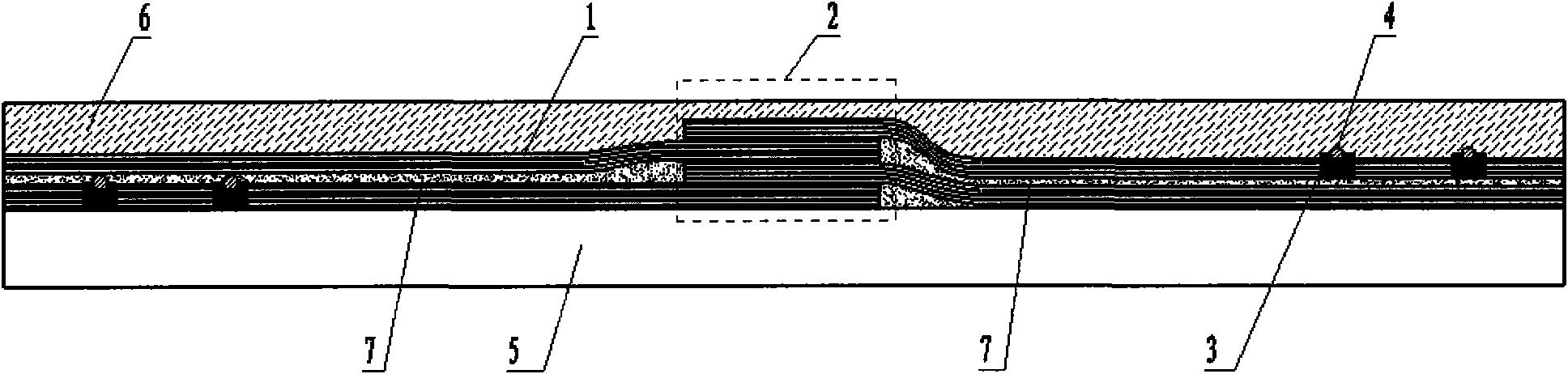

[0040] Embodiment 2: as figure 2 as shown,

[0041] It is basically the same as Example 1, except that the overlapping interface of Example 1 is a two-bundle fiber laminated structure, while the overlapping interface of Example 2 is a multi-bundle fiber laminated structure, forming a multi-layer fiber interface Sensitive layer, and an insulating layer 7 between the fiber bundle interfaces of the non-overlapping sections.

Embodiment 3

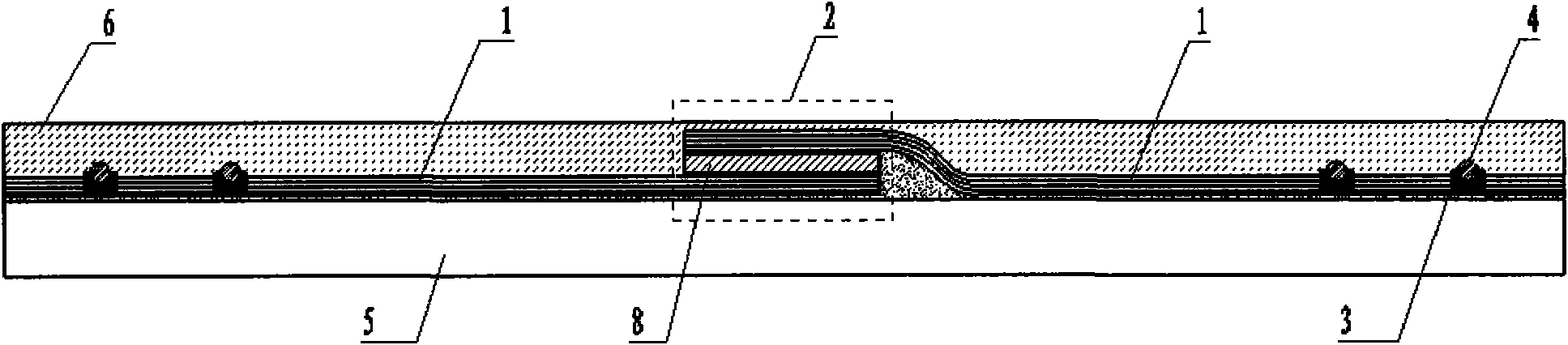

[0042] Embodiment 3: as image 3 as shown,

[0043] It is basically the same as Example 1, except that in Example 1, two bundles of carbon fibers are directly overlapped, while in Example 3, there is an interlayer 8 at the overlapping interface, and the interlayer material is selected from fixed-length continuous carbon fiber, chopped carbon fiber felt, or carbon fiber. fabric, or other conductive substances such as carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com