Method for controlling port by PLC in numerically-controlled machine tool system

A technology of numerical control machine tools and control ports, which is applied in the direction of program control and electrical program control in sequence/logic controllers, and can solve the problems of non-identity, uneconomical, and labor-intensive, etc., and achieves a wide range of applications and simple processing procedures Convenience, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

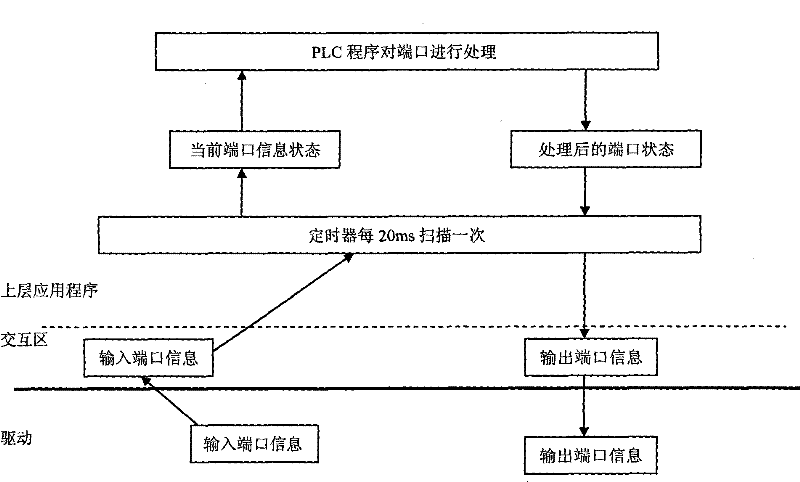

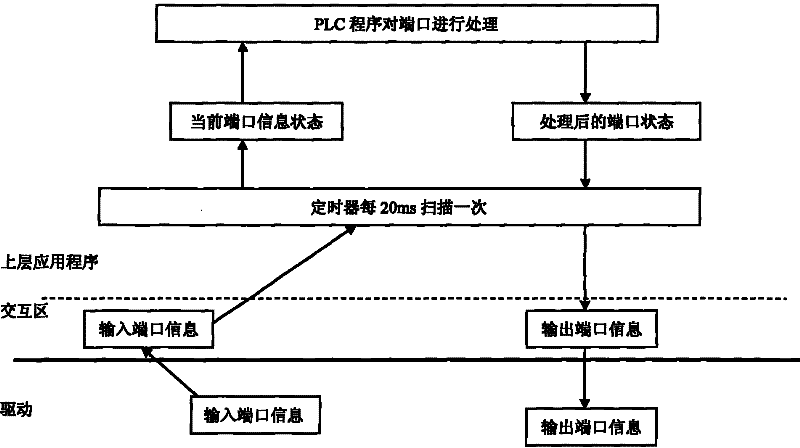

[0023] Such as figure 1 Shown, the method for PLC control port in the numerical control machine tool system of the present invention, it comprises the steps:

[0024] (1) PLC obtains current port information including port address information from timer Timer;

[0025] (2) process the port by the PLC instruction according to the obtained port information through the PLC;

[0026] (3) Return the obtained port information to the driver R0.

[0027] In the present invention, the timer Timer obtains the current port information through cyclic scanning, and the scanning period of the timer Timer is to scan once every 20 milliseconds to ensure the accuracy of the port information.

[0028] In the present invention, the ports are divided into input ports and output ports, and the ports are addressed according to channels, and each channel has 32 numbers, that is, each channel can accommodate 32 ports.

[0029] Wherein, in the present embodiment, the input port and the output port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com