Metal injection-molding-system and process for making foamed alloy

An injection molding, metal foam technology, applied in the field of metal injection molding systems, can solve the problems such as the inability to make magnesium foam parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

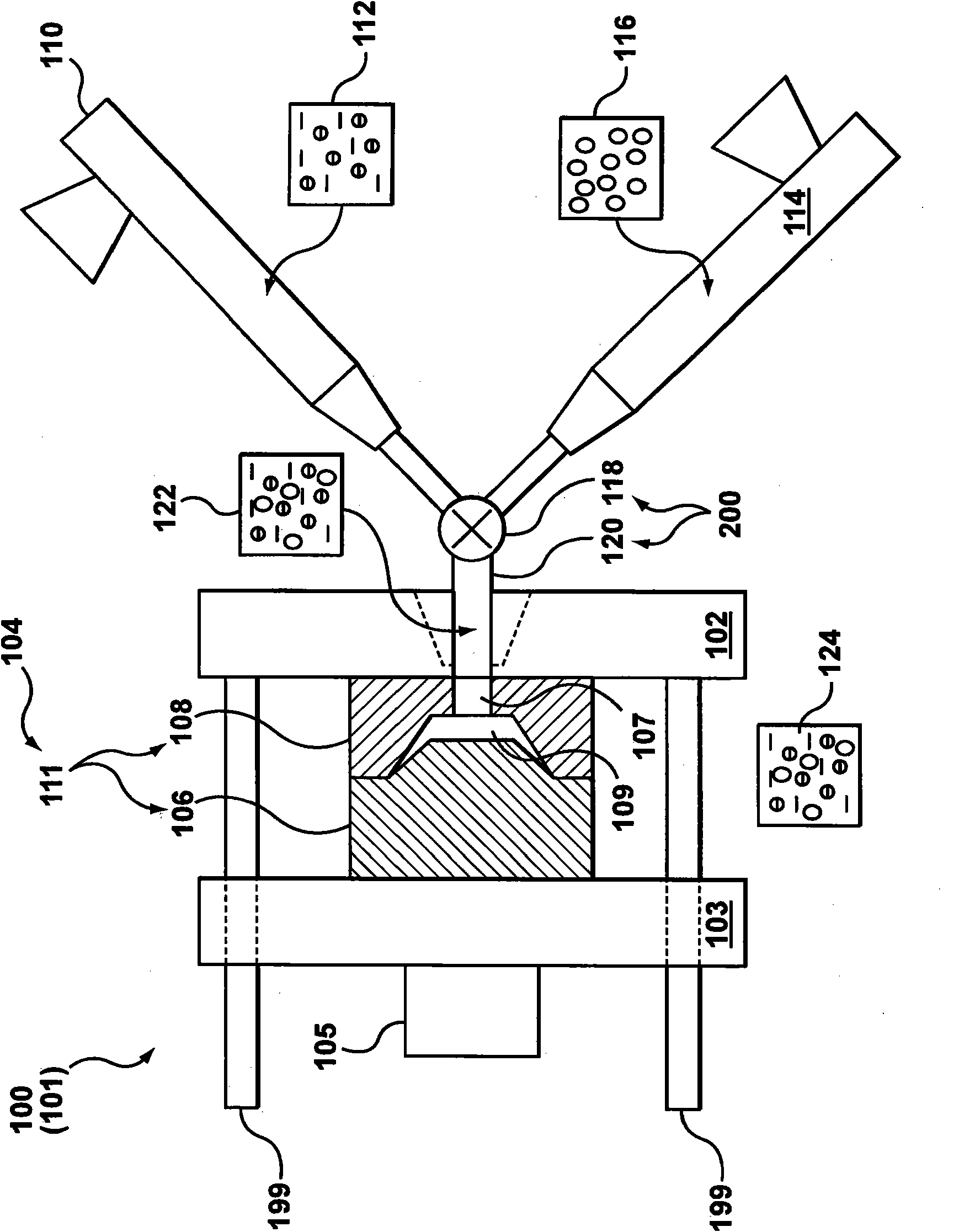

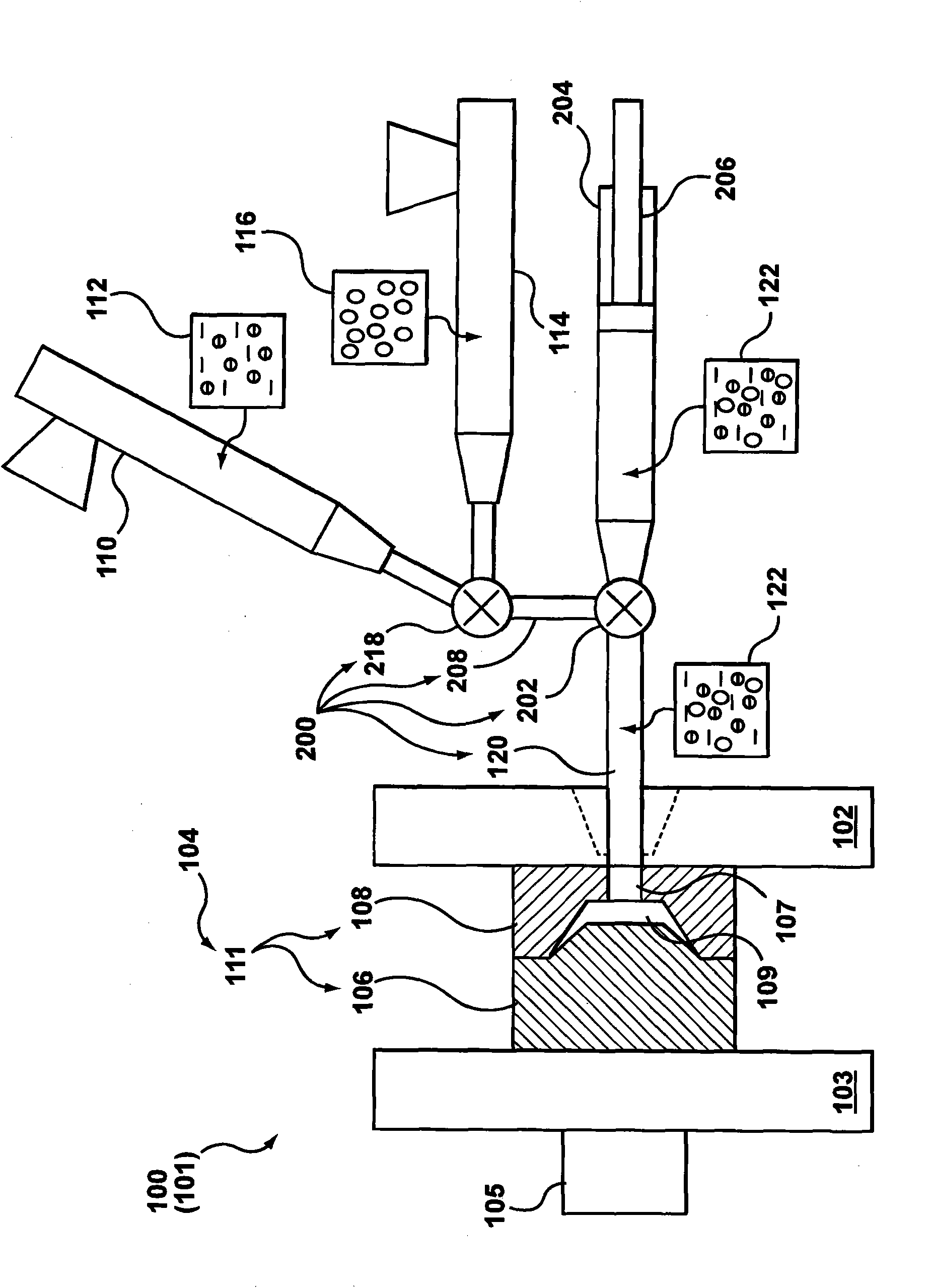

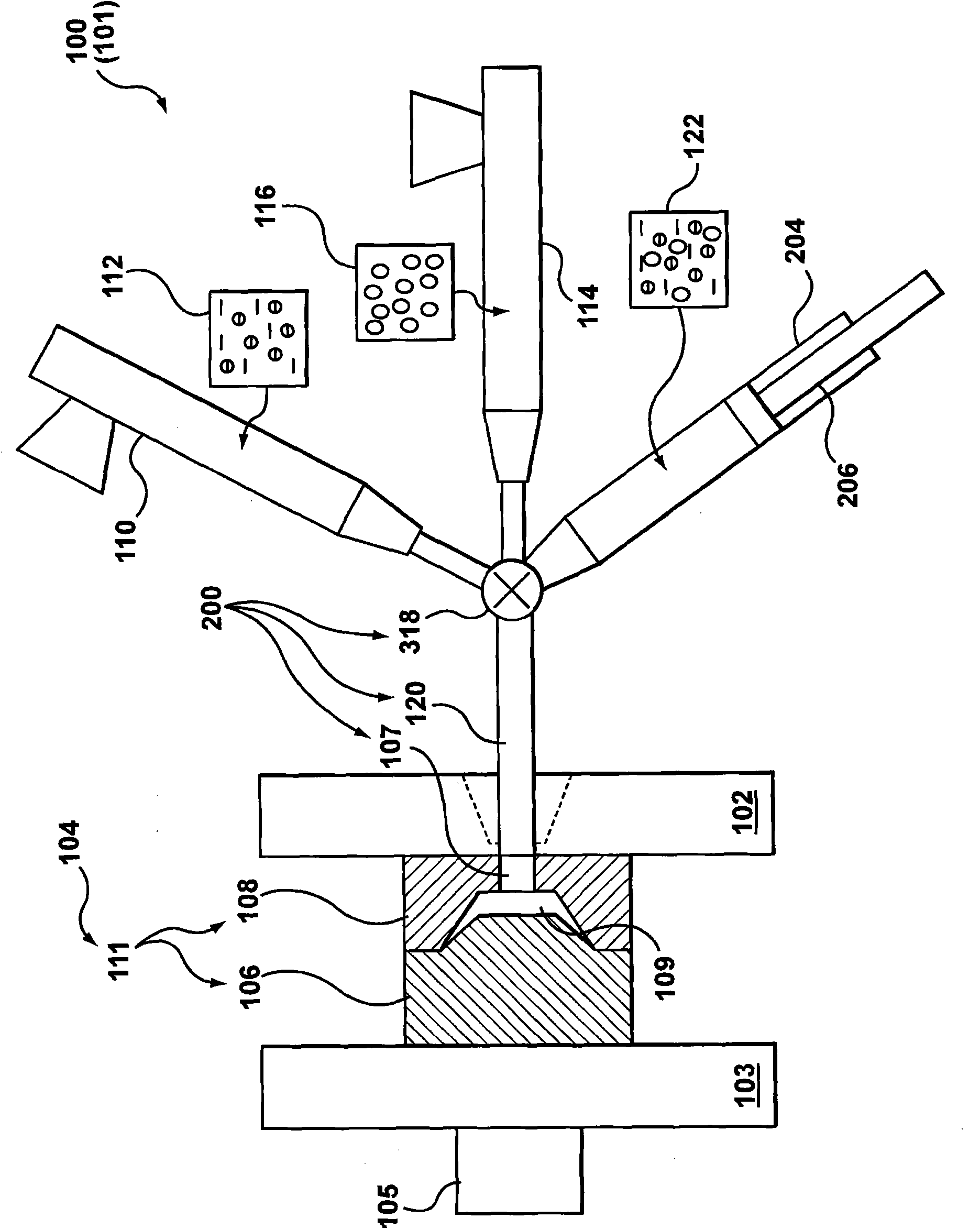

[0065] figure 1 A schematic representation of a metal injection molding system 100 (hereinafter referred to as "system 100") according to a first non-limiting embodiment is depicted. Preferably, the system 100 includes a metal injection molding system 101. The system 100 may include some components known to those skilled in the art, and these known components will not be described here; these known components are at least partially described in the following textbooks (for example): (i) Oss Wald / Turng / Gramann (Osswald / Turng / Gramann)" Injection Molding Manual "(ISBN: 3-446-21669-2; Publisher: Hanser); (ii) "Rosato" and "Rosato" Injection Molding Manual "(ISBN: 0-412-99381-3; Publisher: Chapman & Hill); and / or (iii) Johannaber's " Injection molding system "The third edition (ISBN 3-446-17733-7).

[0066] According to a first non-limiting embodiment, the system 100 includes a first injection mechanism 110 (hereinafter referred to as "mechanism 110") which is configured to proce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap