Tape drive

A driving device, driving belt technology, applied in the direction of inking device, non-electric variable control, comparison unit, etc., can solve problems such as difficult to obtain performance, and achieve the effect of large acceleration and deceleration, simple mechanical assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

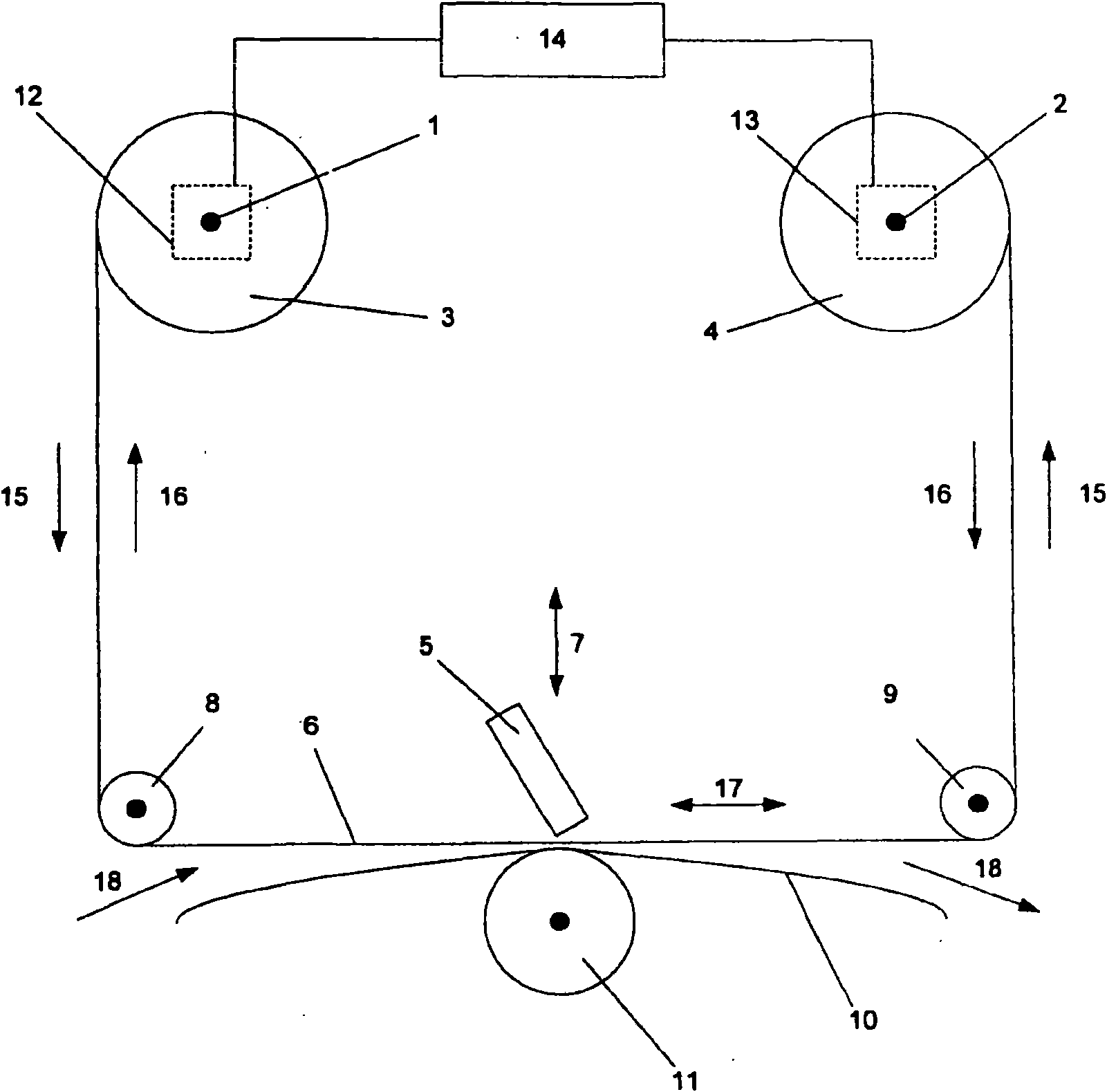

[0029] [29] cf. figure 1 , which schematically illustrates a belt drive suitable for use in a thermal transfer printer according to the present invention. The first shaft 1 and the second shaft 2 support a supply reel 3 and a take-up reel 4, respectively. The supply reel 3 is initially wound with a roll of unused tape, while the take-up reel 4 is initially not carrying any tape. As the tape is used, the used portion of the tape is transferred from the supply reel 3 to the take-up reel 4 . A movable print head 5 is provided which is movable relative to the belt 6 at least in a first direction indicated by arrow 7 . Belt 6 extends from supply reel 3 to take-up reel 4 around rollers 8 , 9 . The path followed by the belt 6 between the rollers 8 and 9 passes in front of the print head 5 . The substrate 10 on which the printed pattern is deposited comes into contact with the belt 6 between the rollers 8 and 9 and the belt 6 is inserted between the print head 5 and the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com