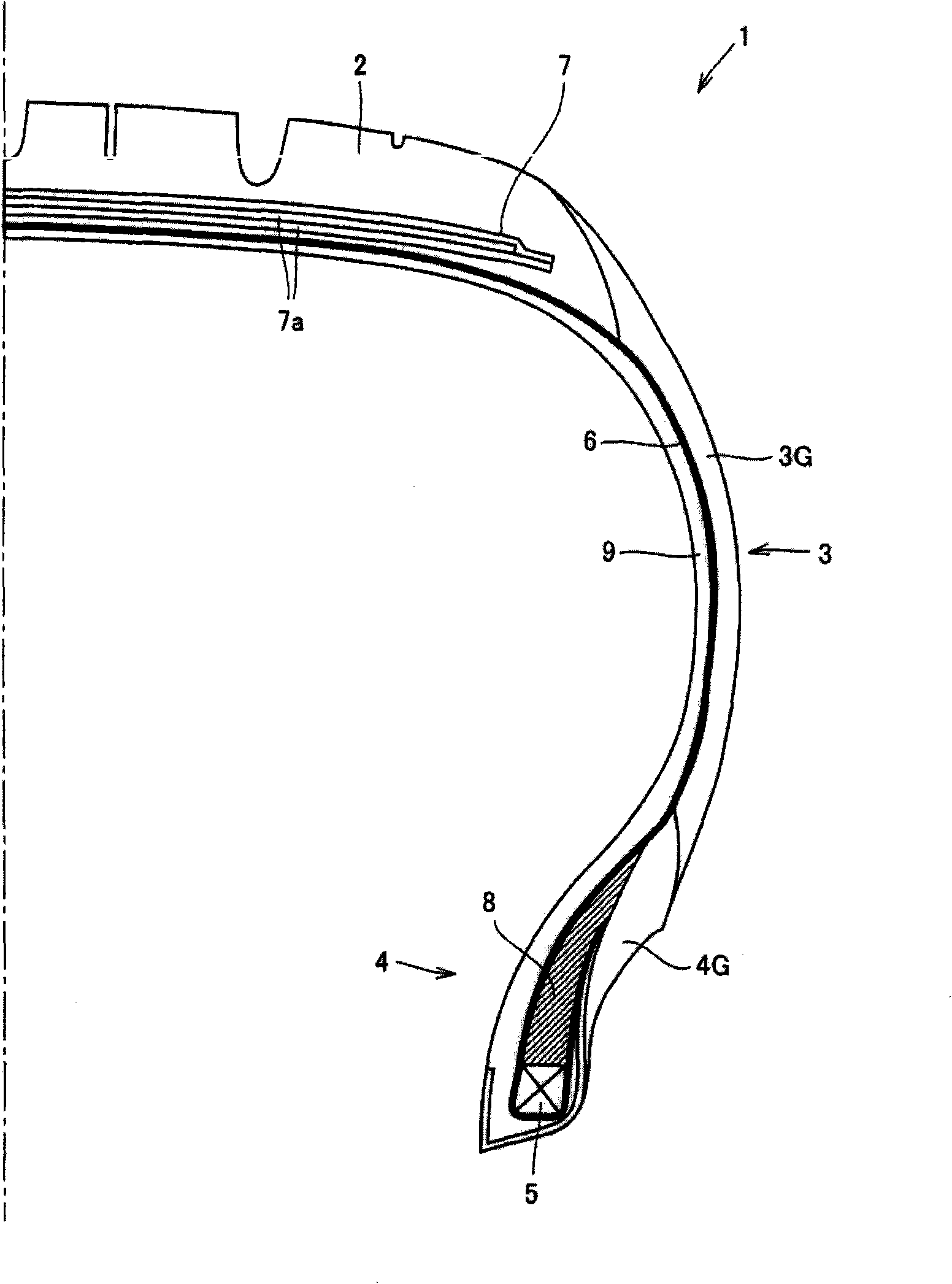

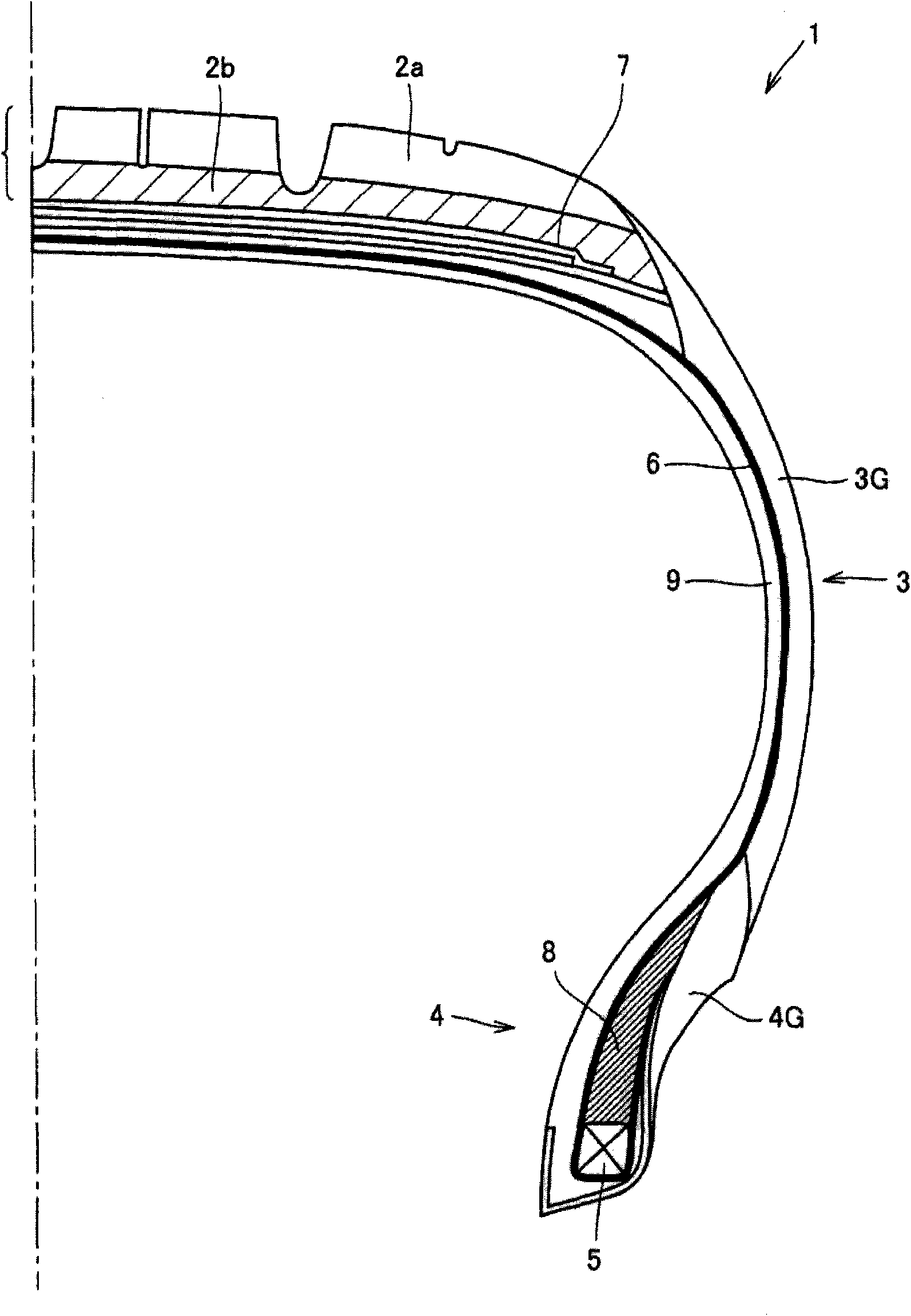

Ply, clinch and tread formed using specified rubber composition, and pneumatic tire utilizing them

A technology of rubber composition and lap joint, which is applied to special tires, tire treads/tread patterns, tire parts, etc., can solve the problem of not considering the performance of rubber composition, etc., and achieve improved mechanical strength and excellent processability , excellent durability and rolling resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

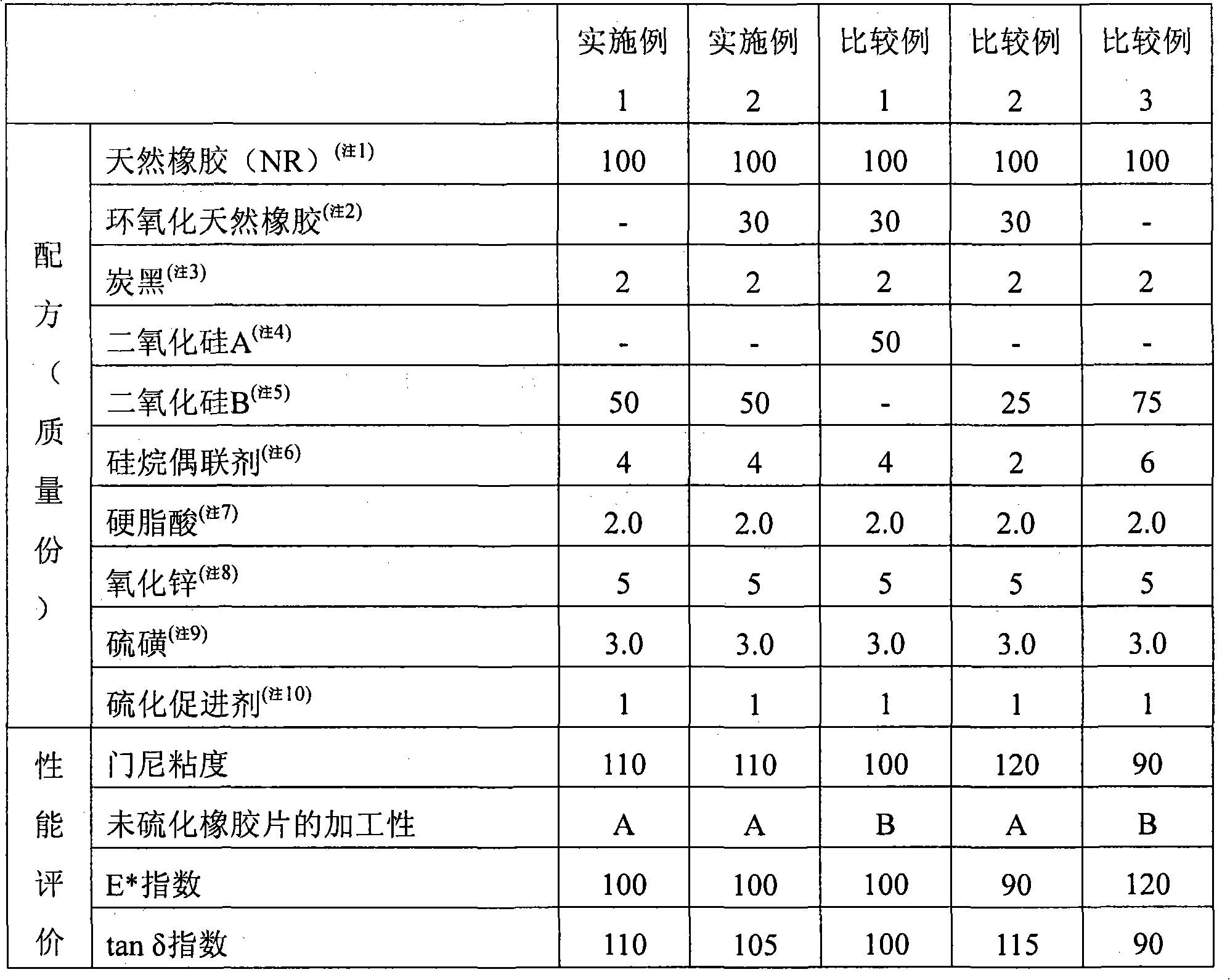

Embodiment 1、2 and comparative example 1~3

[0123] According to the formulation shown in Table 1, the formulation components other than sulfur and the vulcanization accelerator were kneaded at 150° C. for 5 minutes using a 1.7 L Banbury Kneader manufactured by Kobe Steel to obtain a kneaded product. The formulation amounts of sulfur and vulcanization accelerator shown in Table 1 were added thereto, and kneaded at 90° C. for 5 minutes using an open mill to prepare an unvulcanized rubber composition.

[0124] The unvulcanized rubber composition obtained above was extruded to produce an unvulcanized rubber sheet of a certain thickness. The unvulcanized rubber sheet was vulcanized at 150° C. for 30 minutes to produce a vulcanized rubber sheet with a certain thickness.

[0125] (Mooney Viscosity Index)

[0126] For the above-mentioned unvulcanized rubber composition, the Mooney viscosity at 130°C was measured according to JIS K6300, and according to the following formula,

[0127] Mooney viscosity index=(Mooney viscosity o...

Embodiment 3~5 and comparative example 4、5

[0149] According to the formula shown in Table 1, use a 1.7L Banbury mixer manufactured by Kobe Steel Works, fill the formula components except sulfur and vulcanization accelerator so that the filling rate is 58%, and mix with a rotating speed of 80rpm Refined for 3 minutes to reach 140°C. Finally, after adding the formula amounts of sulfur and vulcanization accelerator shown in Table 2 to the obtained kneaded product, using an open mill, kneaded at 80° C. for 5 minutes to obtain the unfinished product of the formula shown in each embodiment and comparative example. Vulcanized rubber composition.

[0150] (Mooney Viscosity Index)

[0151] According to JIS K6300, the Mooney viscosity of the unvulcanized rubber composition was measured at 130°C, and the Mooney viscosity of Comparative Example 1 was 100, according to the following calculation formula,

[0152] Mooney viscosity index=(Mooney viscosity of Comparative Example 1)÷(Mooney viscosity of each Example and each Comparati...

Embodiment 6、7 and comparative example 6、7

[0178] According to the formula shown in Table 3, use a 1.7L Banbury mixer made by Kobe Steel Works, fill the formula components except sulfur and vulcanization accelerator so that the filling rate is 58%, and mix with a rotating speed of 80rpm Refined for 3 minutes to reach 140°C. Add the formula amounts of sulfur and vulcanization accelerator shown in Table 3 to the obtained kneaded product, and knead at 80°C for 5 minutes using an open mill to obtain unvulcanized rubber compositions with the formulas shown in each example and comparative example. .

[0179] (Mooney Viscosity Index)

[0180] According to JIS K6300, the Mooney viscosity of the unvulcanized rubber composition was measured at 130°C, and the Mooney viscosity of Comparative Example 1 was 100, according to the following calculation formula,

[0181] Mooney viscosity index=(Mooney viscosity of Comparative Example 1)÷(Mooney viscosity of each Example and each Comparative Example)×100 represents an index. The larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com