Automatic placement machine for placing electrical and/or optical components on substrates

A technology of electrical components and optical components, applied in the direction of electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

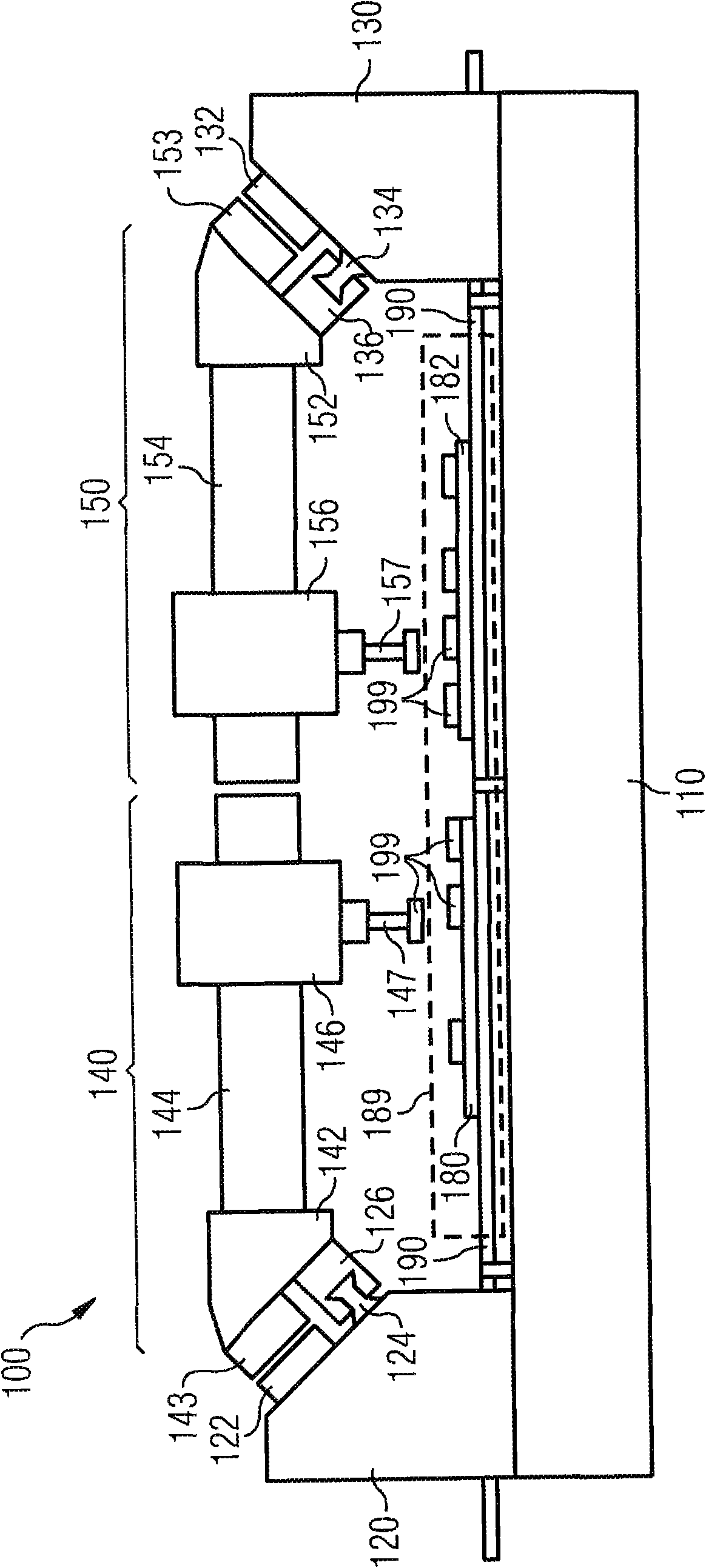

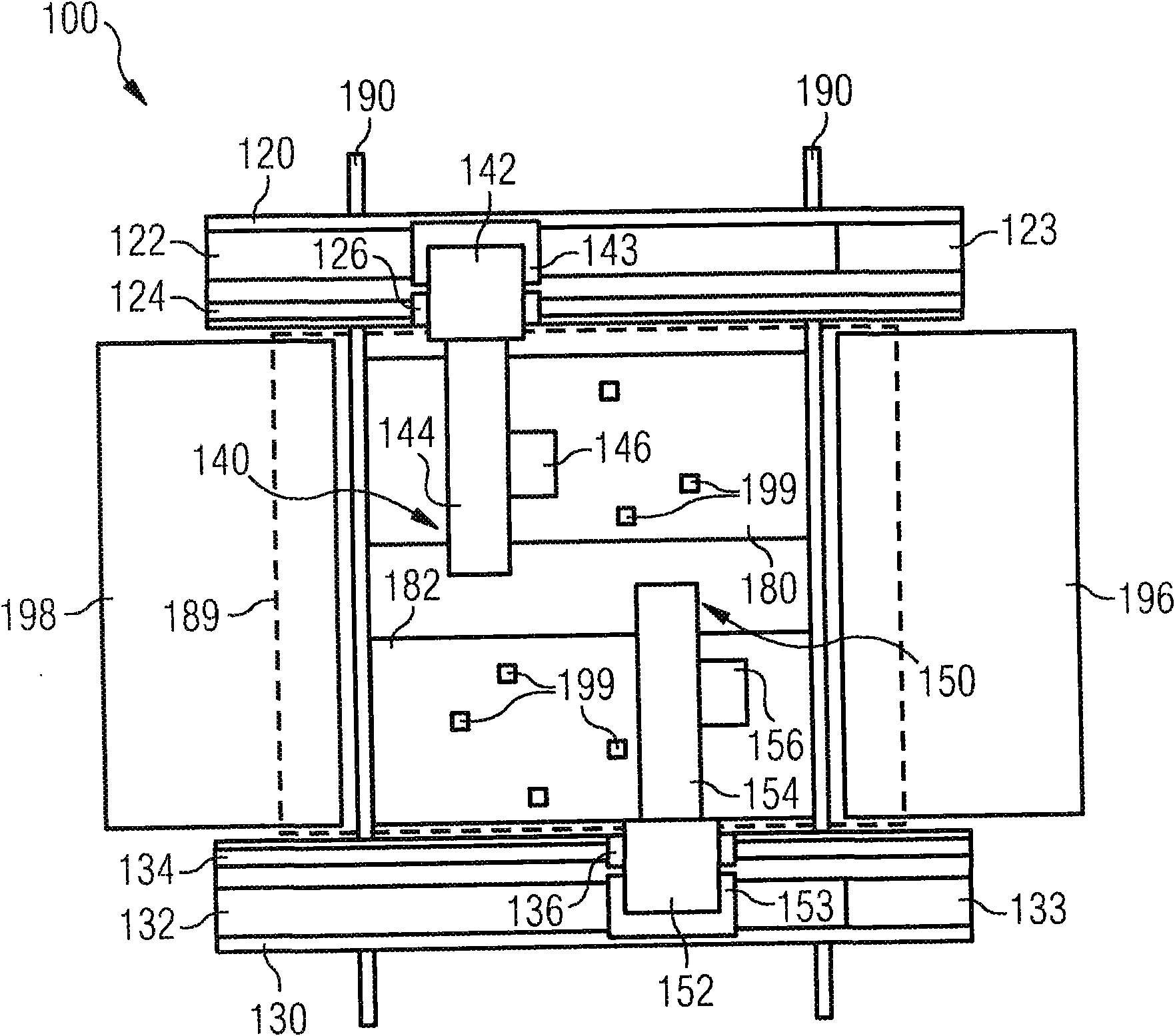

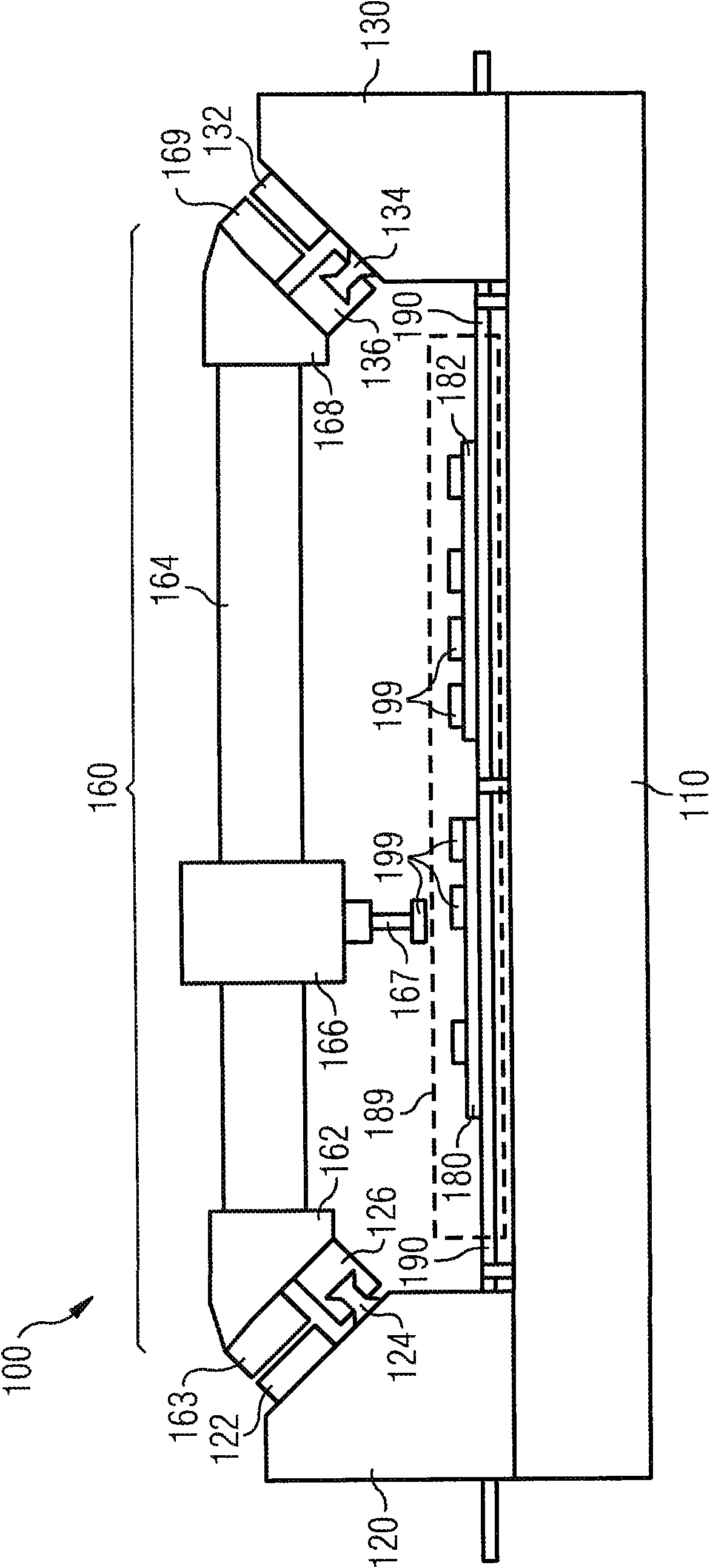

[0092] figure 1 An automatic assembly machine 100 is shown with a base unit 110 and two stands 120 , 130 . Guide rails 124 , 134 are respectively fixed on the brackets for guiding the door frame mounted on the automatic assembly machine 100 . In addition, magnetic rails 122 , 132 are installed on the brackets 120 , 130 respectively, which are used to drive the door frame of the automatic assembly machine 100 .

[0093] The automatic assembly machine 100 has a first door shelf unit 140 which is in figure 1 is shown in the left portion of the automatic assembly machine 100 . The first portal subunit 140 , which is also referred to below as first stub portal 140 , has an assembly head 146 with a suction duct 147 for picking up, transporting and setting down components 199 . The drive of the first cropping gantry 140 takes place via a linear motor drive unit 143 mounted on the gantry head 142 of the cropping gantry 140 and interacting with the left-hand magnetic rail 122 . The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap