Multifunctional drink extraction device and application thereof

An extraction device and multi-functional technology, which is applied in the field of multi-functional beverage extraction devices, can solve the problems of bulky, complex manufacturing process, use conditions and portability limitations, and achieve the effect of simple mechanical structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

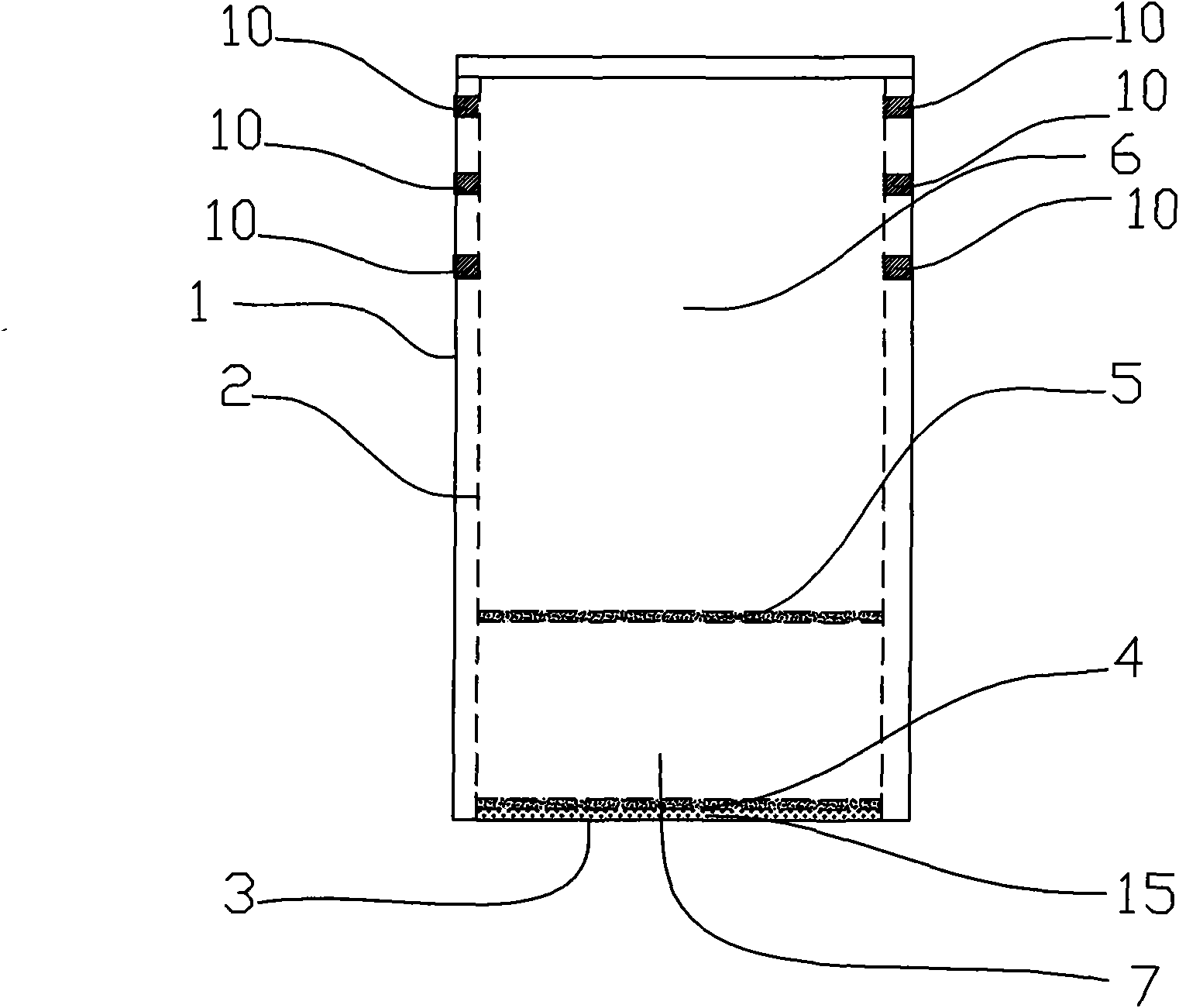

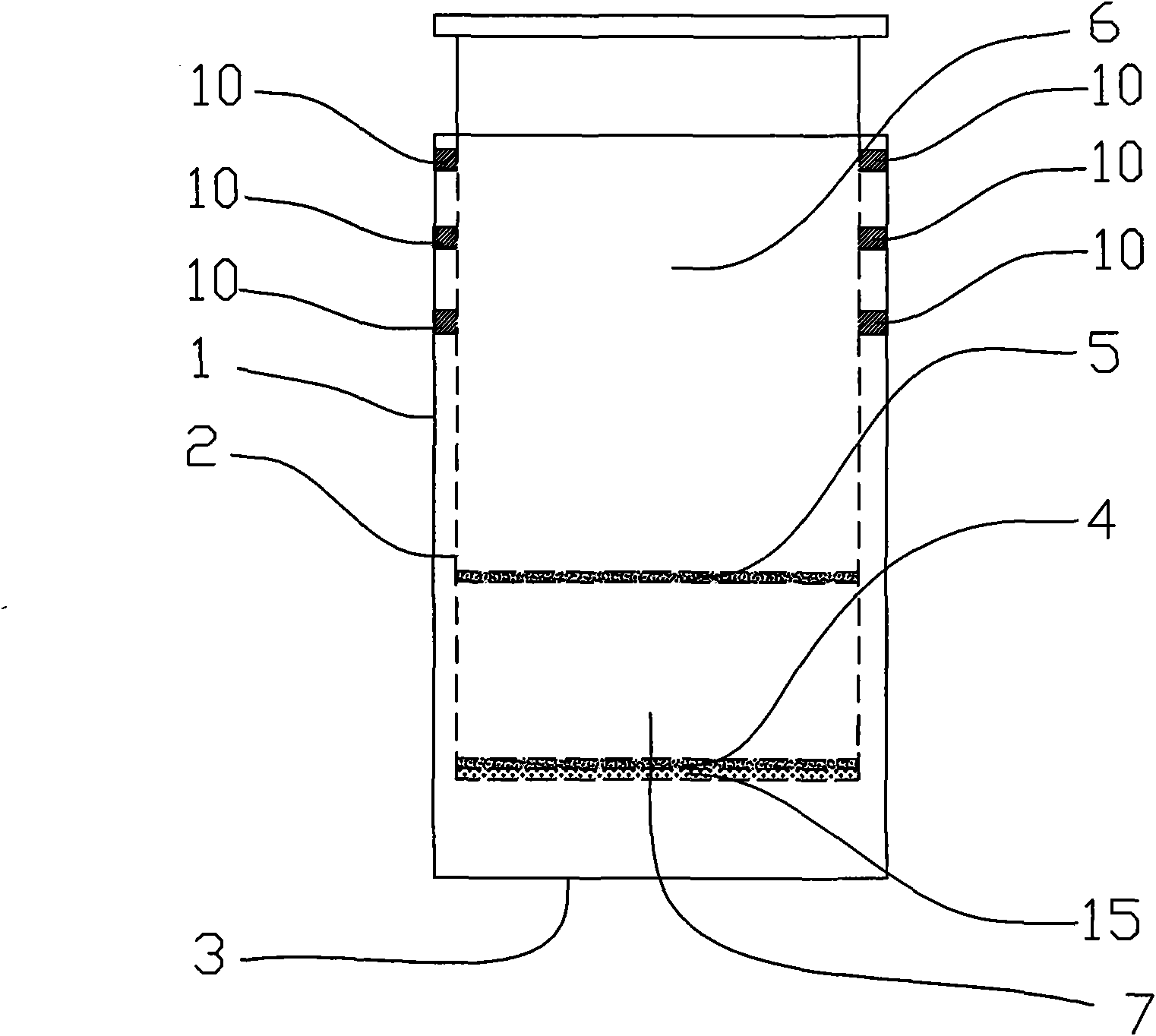

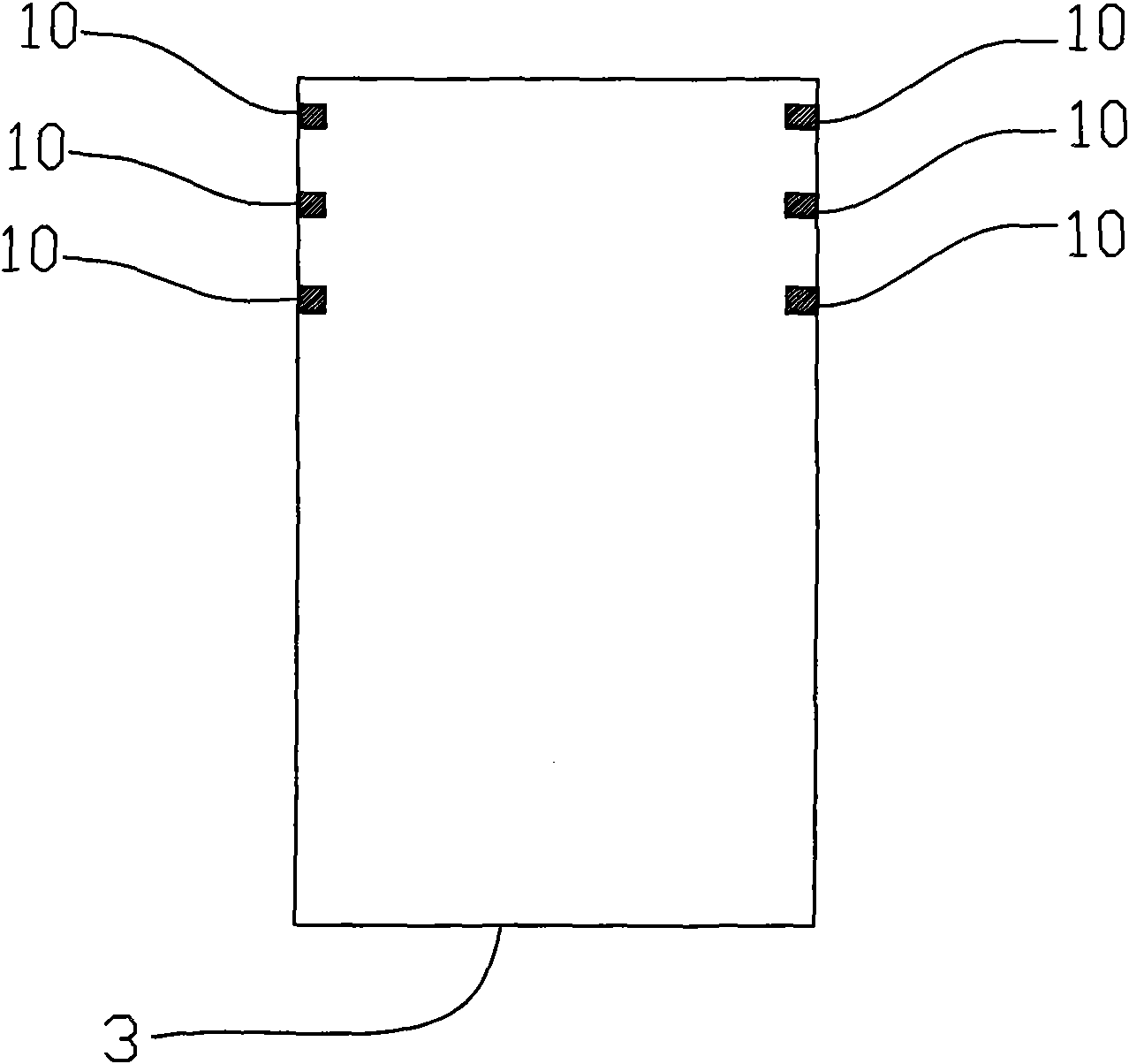

[0067] Such as figure 1 and 2 The multifunctional beverage extracting device A shown includes an outer container 1 (such as image 3 shown) and inner container 2 (as Figure 4 As shown), the inner container 2 is placed in the outer container 1, and the outer container 1 and the inner container 2 are movably socketed and detachable. The outer container includes a sealed bottom surface 3, and the bottom surface of the inner container is provided with a bottom filter 4. The lower side of the container is provided with a water retaining sheet 15, and a hole is arranged on the water retaining sheet. The inner cavity of the inner container is divided into an upper cavity 6 and a lower cavity 7 by a porous baffle 5. The inner wall of the outer container is provided with a sealing ring 10, and the filter screen on the bottom surface 4 and porous baffle 5 are detachable.

[0068] Realization of multiple extraction methods:

[0069] Espresso pressurized extraction:

[0070] Inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com