Separator and flowmeter assembly with same

A separator and flow meter technology, applied in the liquid separation and gas fields, can solve the problems of high price, large volume of separation equipment, complicated adjustment and maintenance work, etc., and achieve the effects of low cost, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

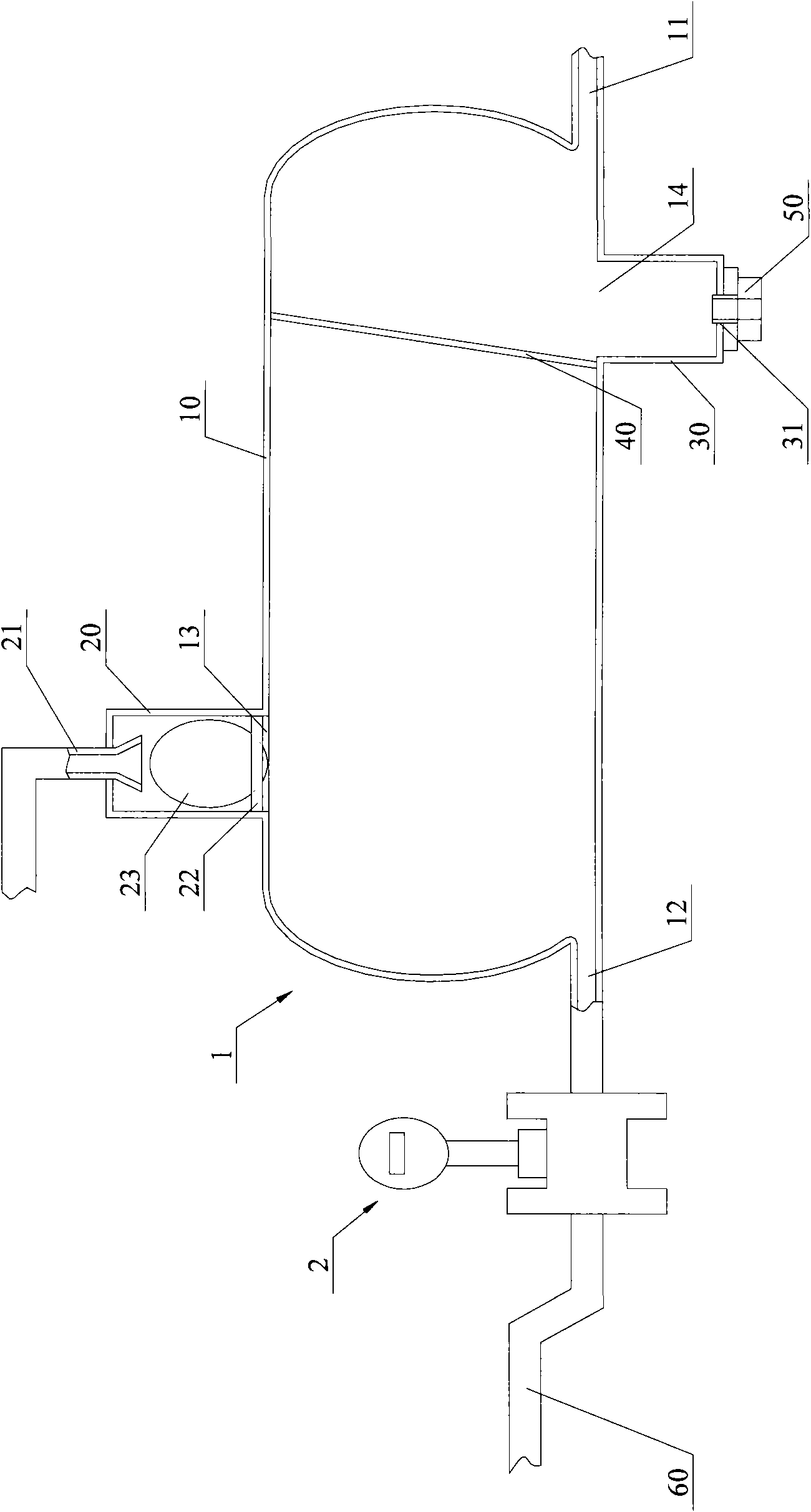

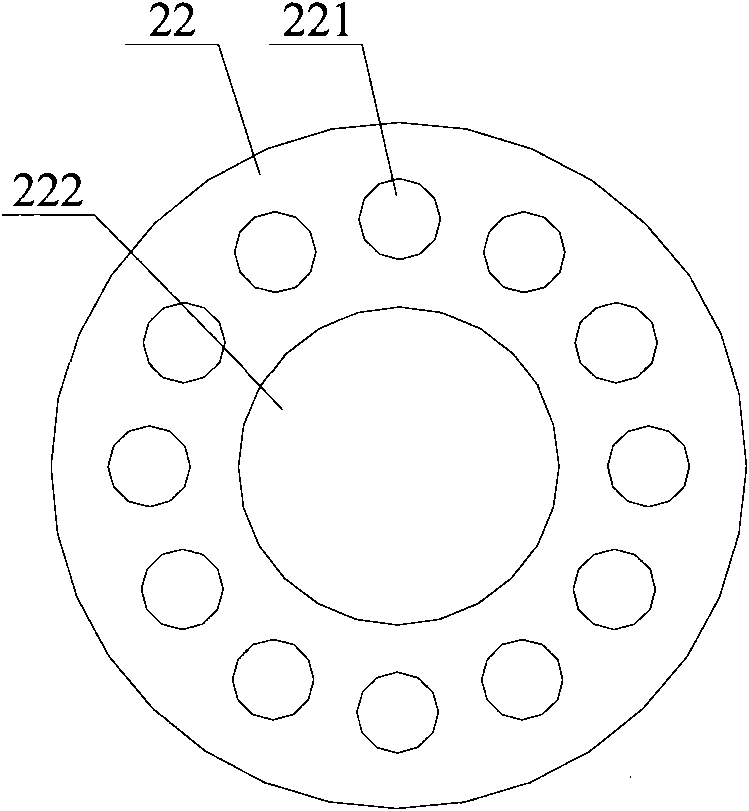

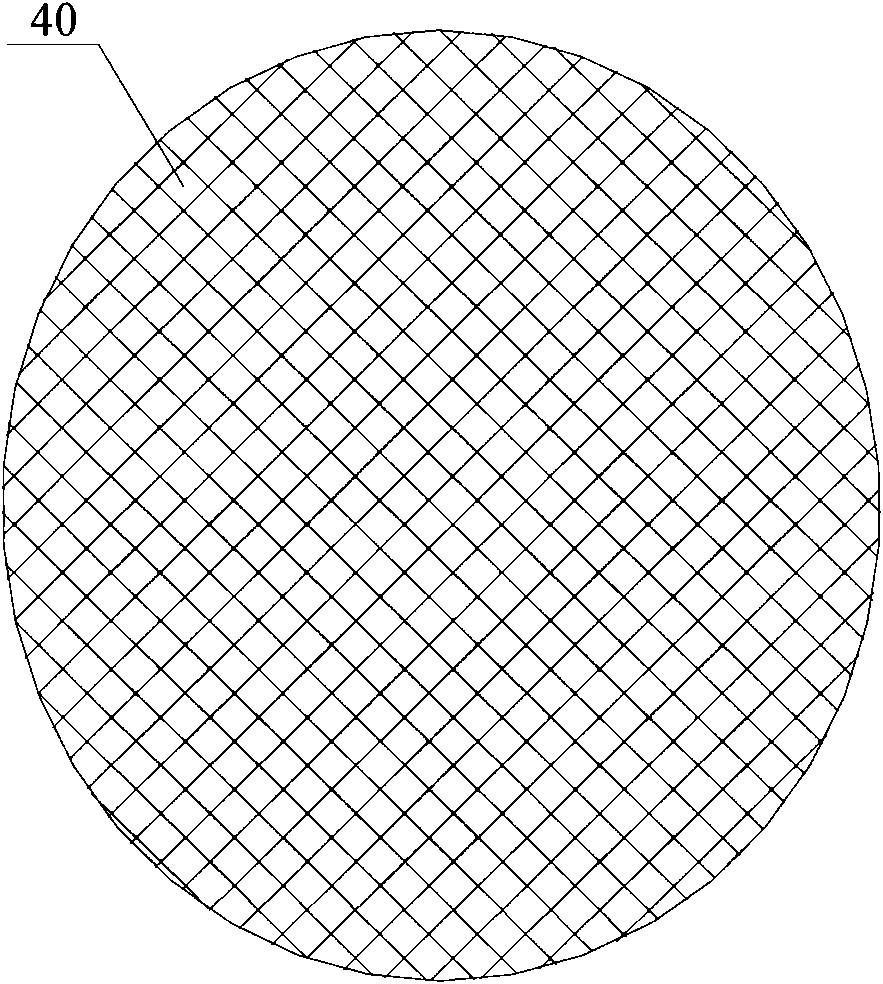

[0026] The core point of the present invention is to provide a separator, which includes a separation tank, a float chamber, an exhaust pipe, a float base and a float ball. Both sides of the separation tank have a liquid inlet and a liquid outlet respectively, and the separator The liquid outlet of the tank is set at the bottom of the separation tank; the float chamber is set at the top of the separation tank and communicates with the separation tank; the exhaust pipe is set at the top of the float chamber and communicates with the The float chamber is connected; the float base is arranged between the separation tank and the float chamber and the separation tank, and there are several ventilation holes on it; the float ball is placed in the float chamber above the float base. When the gas-liquid two-phase fluid enters the separation tank from the liquid inlet of the separation tank, the liquid sinks at the bottom of the separation tank and flows out through the liquid outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com