Extruder arrangement

A technology of extrusion equipment and extruder, applied in mechanical equipment, gear transmission device, material forming press, etc., can solve the problems of vibration sensitivity and high wear of shift sleeve, and achieve the effect of simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

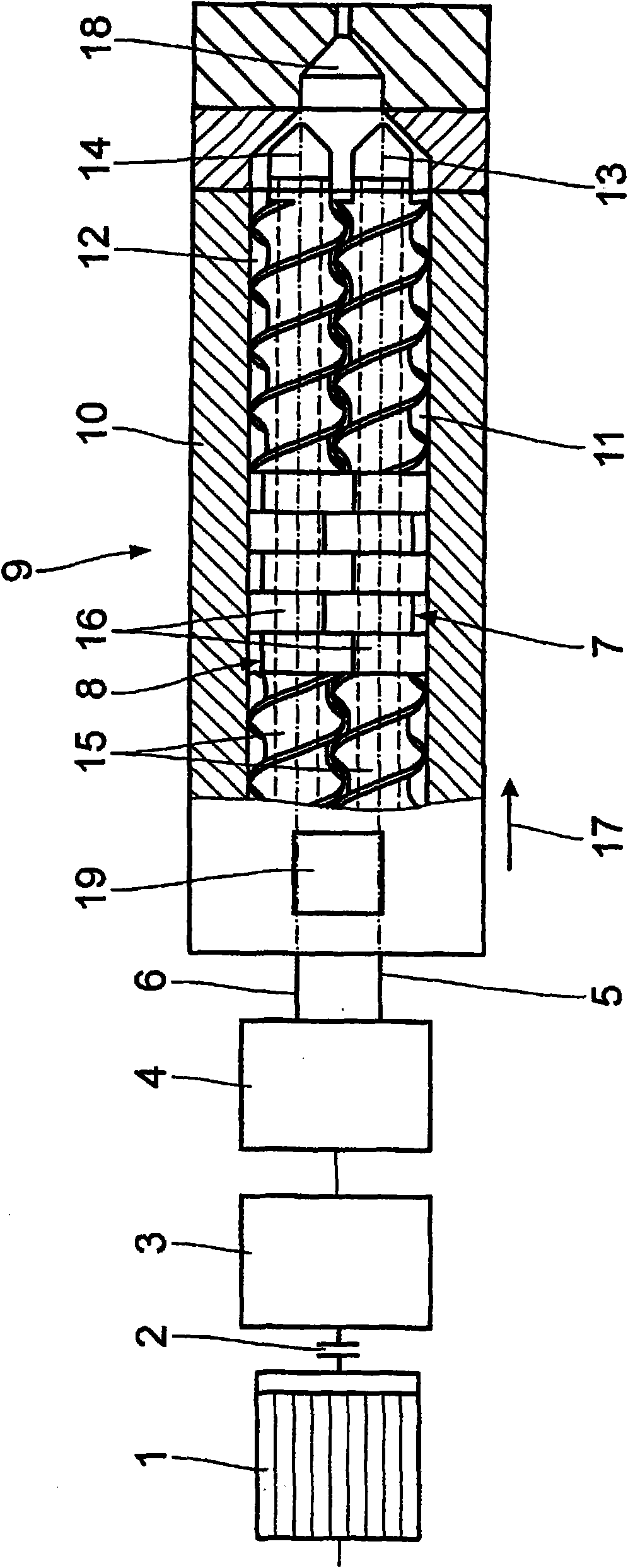

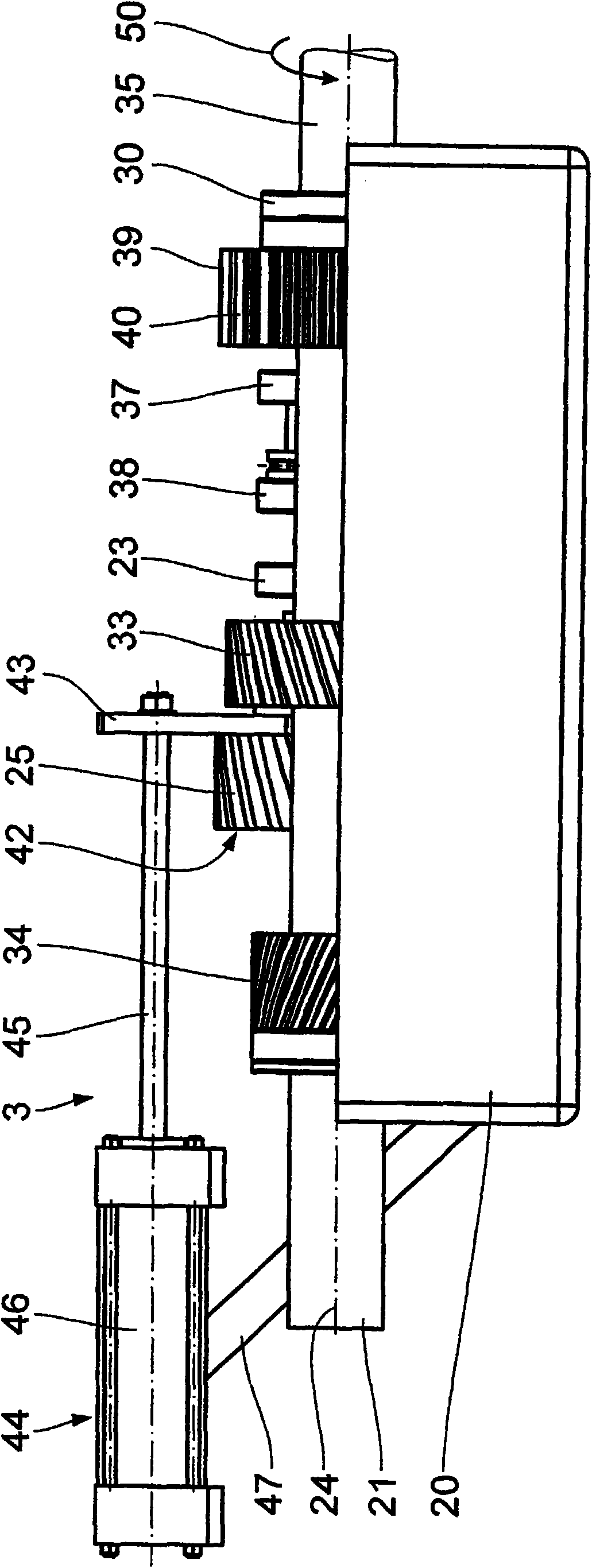

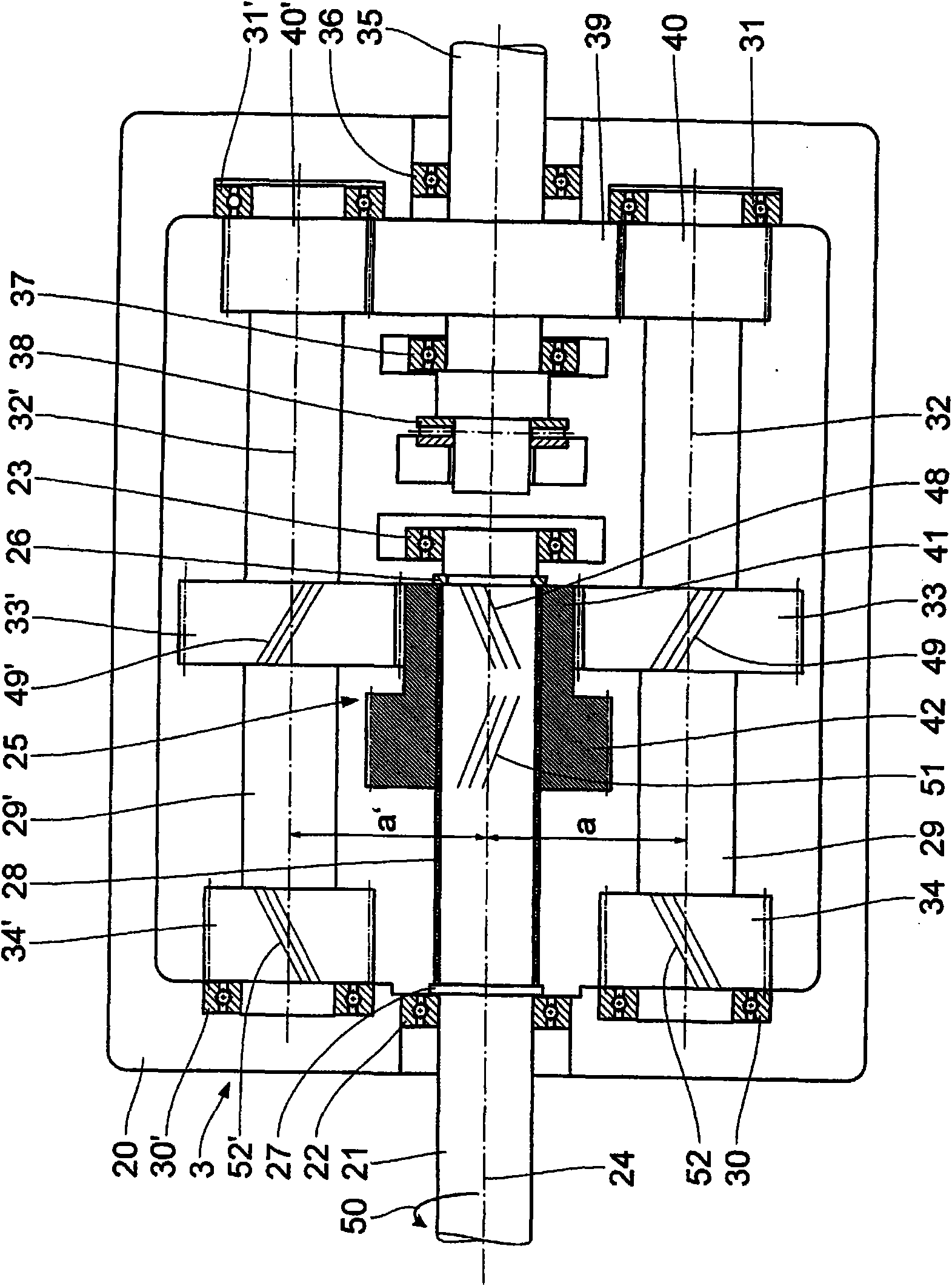

[0016] exist figure 1 The extrusion system shown in has a drive motor 1 which is connected downstream via a clutch / engagement device 2 to a transmission 3 . A conventional transfer case 4 is connected on the speed changer 3, and two co-rotating output shafts 5, 6 are drawn from the transfer case, and the output shafts are connected with the screw shaft / worm screw 7, 8 of an extruder 9 connect. The extruder 9 has a housing 10, in which two 8-shaped staggered holes 11, 12 are arranged, and the holes 11, 12 are connected with the output shafts 5, 6 and the screw shafts 7, 8 in the housing 10. The axes 13, 14 are coaxial. On the screw shafts 7 and 8, a screw part 15 and a molding / mixing part 16 are provided in pairs, respectively. At the downstream end of the housing 10 in the conveying direction 17 of the screw shafts 7 , 8 there is provided a discharge opening 18 for (discharging) the product processed in the extruder 9 in the transfer case. 4 Nearby the material input throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com