Novel locomotive traction transmission device

A technology for traction transmission and locomotives, applied in the direction of power units, electric power units, vehicle components, etc., can solve the problems of uneven impact load, increase the wall thickness of armature hollow shaft, and corrugated wear of rails, etc., and achieve simplified processing and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

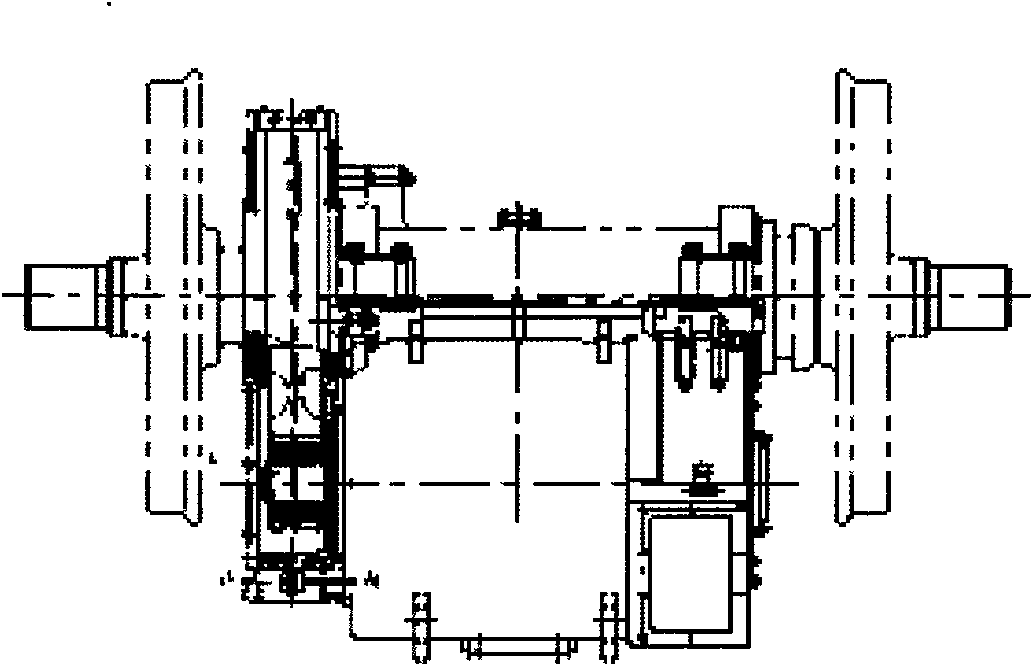

[0098] Now in conjunction with accompanying drawing, the present invention is described in further detail:

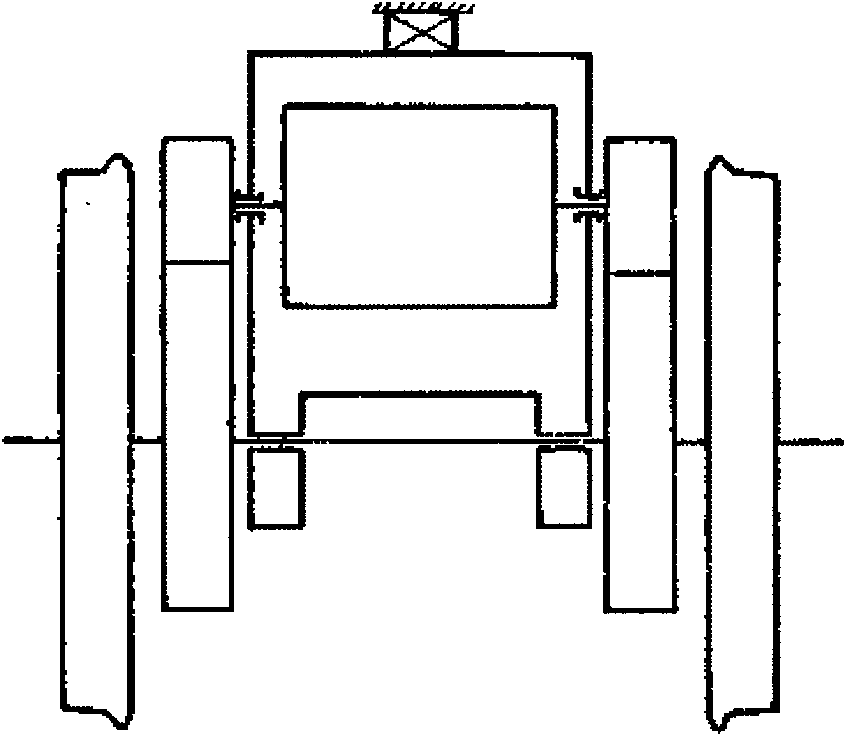

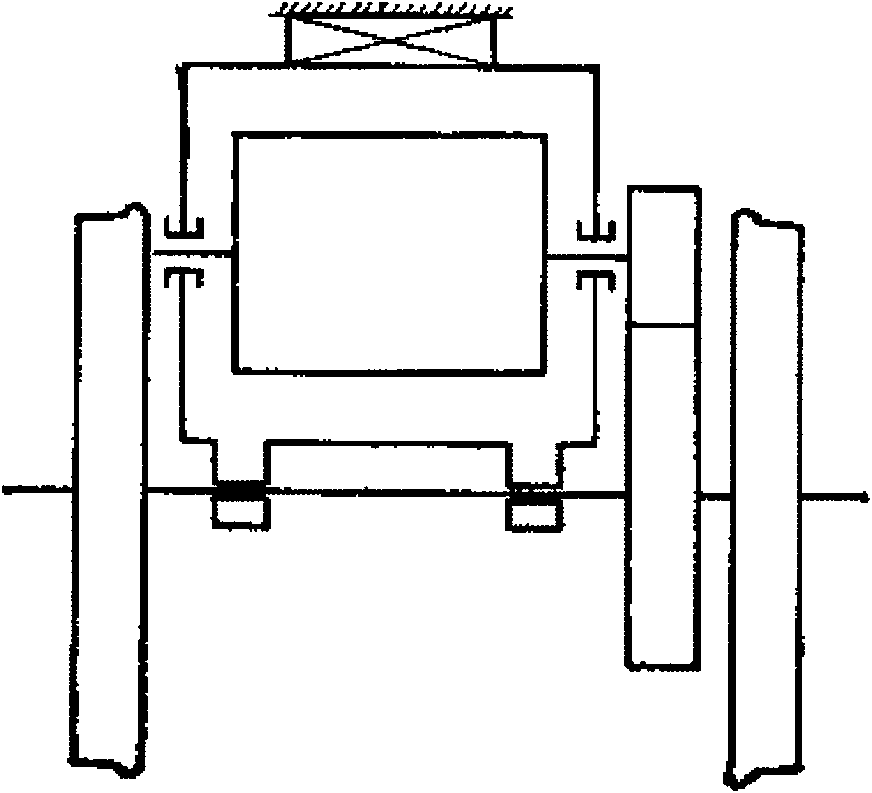

[0099] Such as Figure 20 As shown, it has the advantages of both bearing type and frame type. When the road condition is good and the locomotive runs at high speed, the vertical impact of the line on the wheel set is small, but the vibration frequency is relatively high. Therefore, frame type should be used. However, when the road conditions are poor and the locomotive must be slowed down, the vertical impact on the wheel set is severe, but the vibration frequency is low, so in this case, the bearing-type traction transmission scheme should be adopted.

[0100] To achieve the above scheme, if Figure 21 The new locomotive traction drive shown includes bogie frame 4, bearing 6, traction motor 7 (including motor stator 7(a), hollow shaft 7(b), motor rotor 7(c)), wheel set 10, locomotive The moving shaft 5 and the traction motor 7 are located between the wheel set 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com