Bottle lifting method and bottle lifting mechanism for bottle unscrambler

A technology of a bottle unscrambler and a chain transmission mechanism, applied in the field of bottle unscramblers, can solve the problems of glass bottles lacking three-dimensional force bearing support, destroying the acid-base concentration of the bottle washing process, wasting resources, etc., and achieving a simple and ingenious structure and stable bottle lifting. Reliable, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

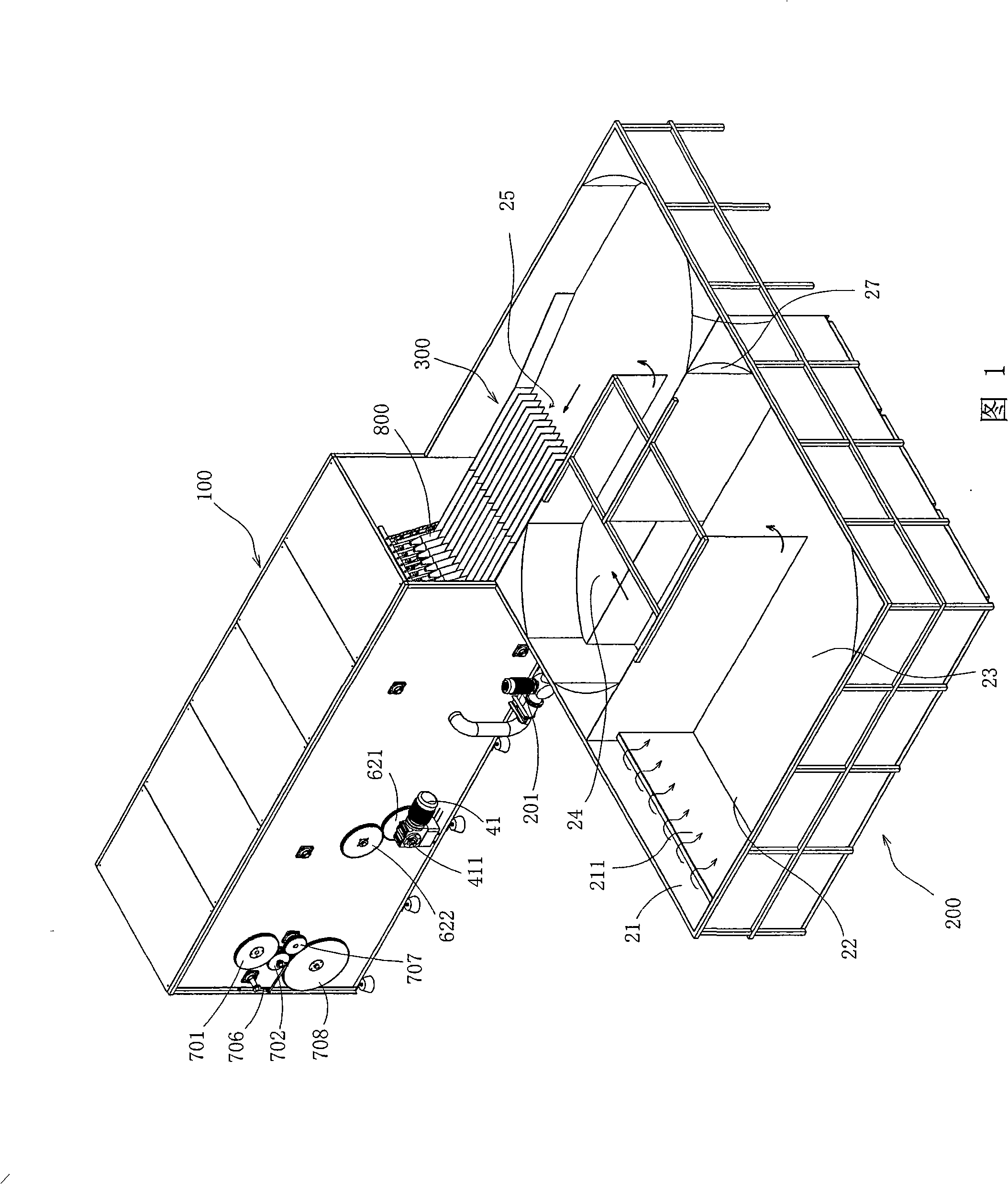

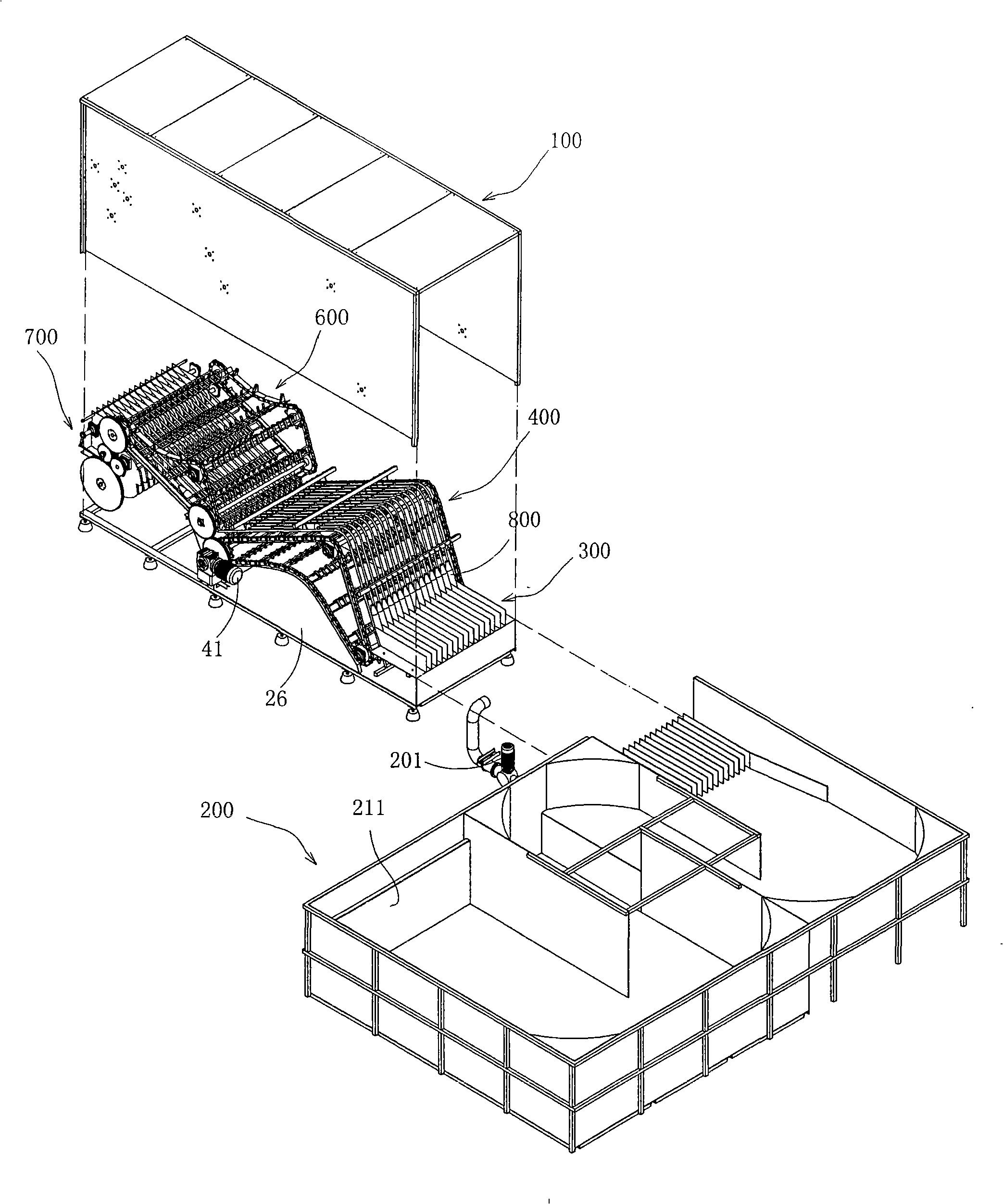

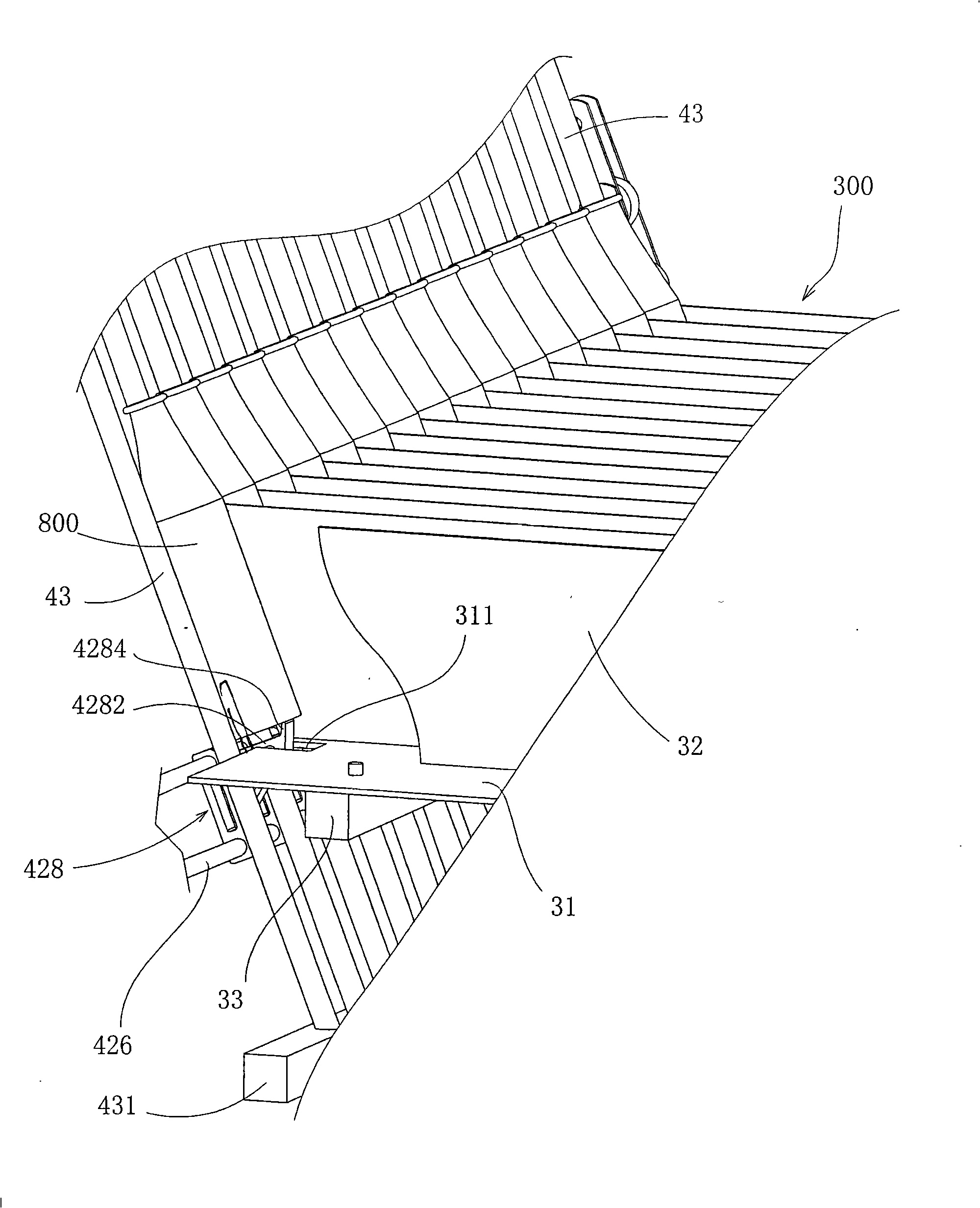

[0033] Such as figure 1 , 2 , 5, the bottle unscrambler of the present invention comprises a housing 100, a control box (not shown in the figure) of a control motor 41 and a pump 201, a liquid pool 200, and a pump that transports liquid to form a circulating fluid flow in the liquid pool 201 and the conveying pipe, the tail end of the liquid pool is connected with the shell, and a lane-dividing mechanism 300 is provided at the joint. The outer end of the lane-dividing mechanism is a bottle lifting mechanism 400, a liquid pouring mechanism, a bottle turning mechanism 600, and a bottle dropping mechanism 700. , wherein, the housing 100 is formed by a steel plate and a bracket structure, and the bottom end is provided with feet placed on the ground; the liquid in the liquid pool can be water, and the depth can be more than twice the height of the bottle. Preparation, the liquid can also be lye or acidic liquid to soak the bottle.

[0034] Such as figure 1 , figure 2 , the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com