Reactor panel for catalytic processes

A reactor and panel technology, applied in the application field of heterogeneous catalytic exothermic or endothermic reactions, can solve the problems of high investment cost, uneven distribution of raw materials, tube blockage and other problems of multi-tubular reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

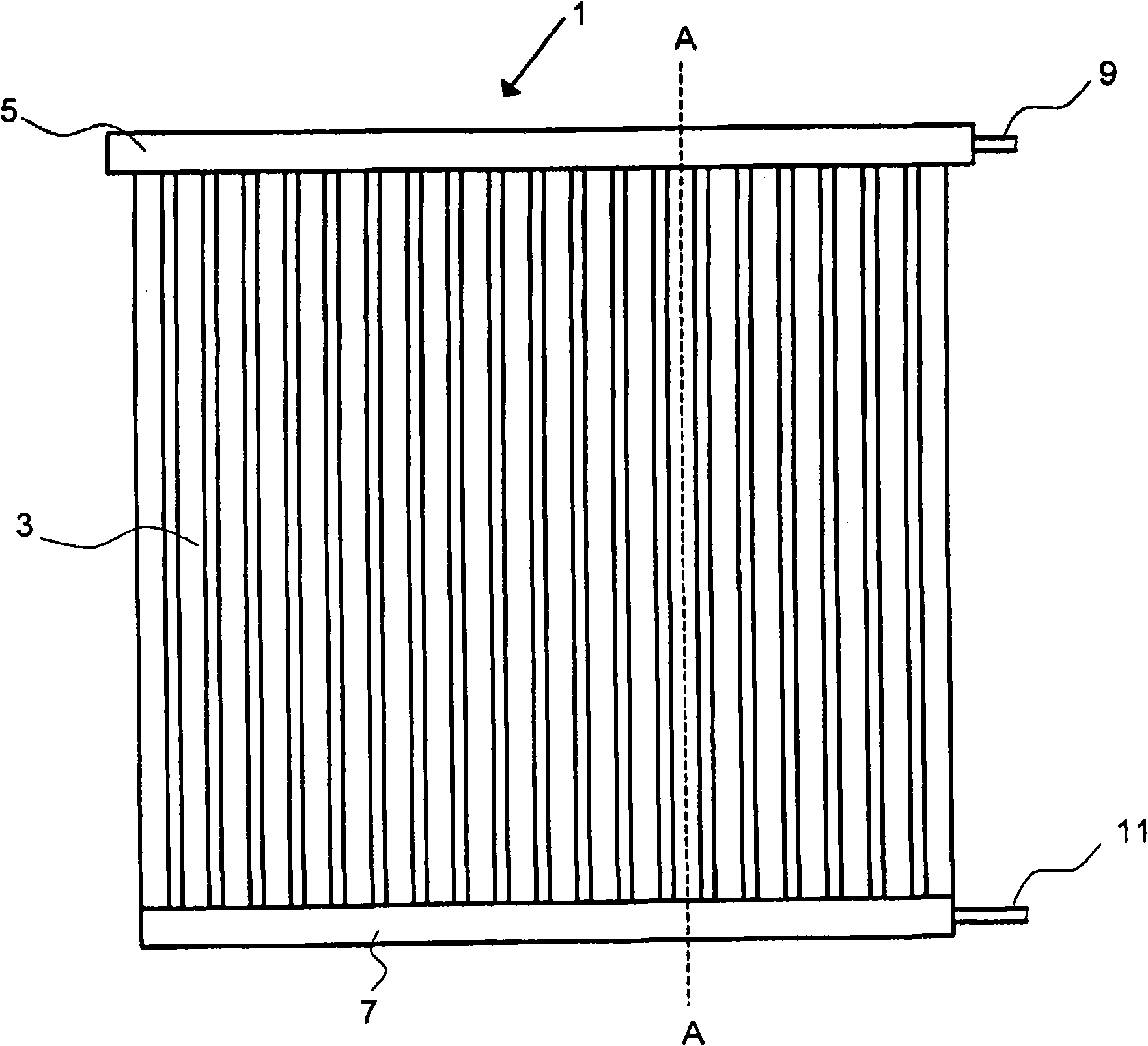

[0098] exist figure 1 shows a panel 1 consisting of tubes 3 as channels each connected to a feedstock header 5 and a product header 7 . The raw material header 5 has a connection portion 9 connected to a raw material line. The product header 7 has a connection 11 to the product line.

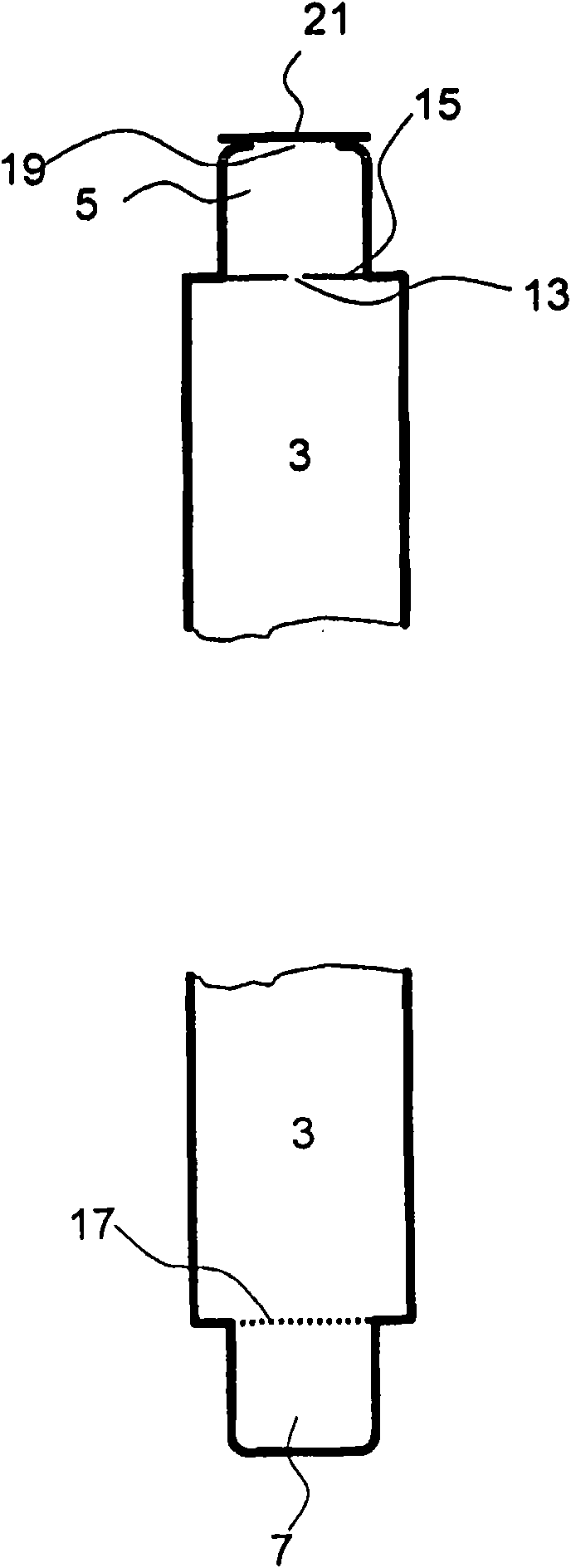

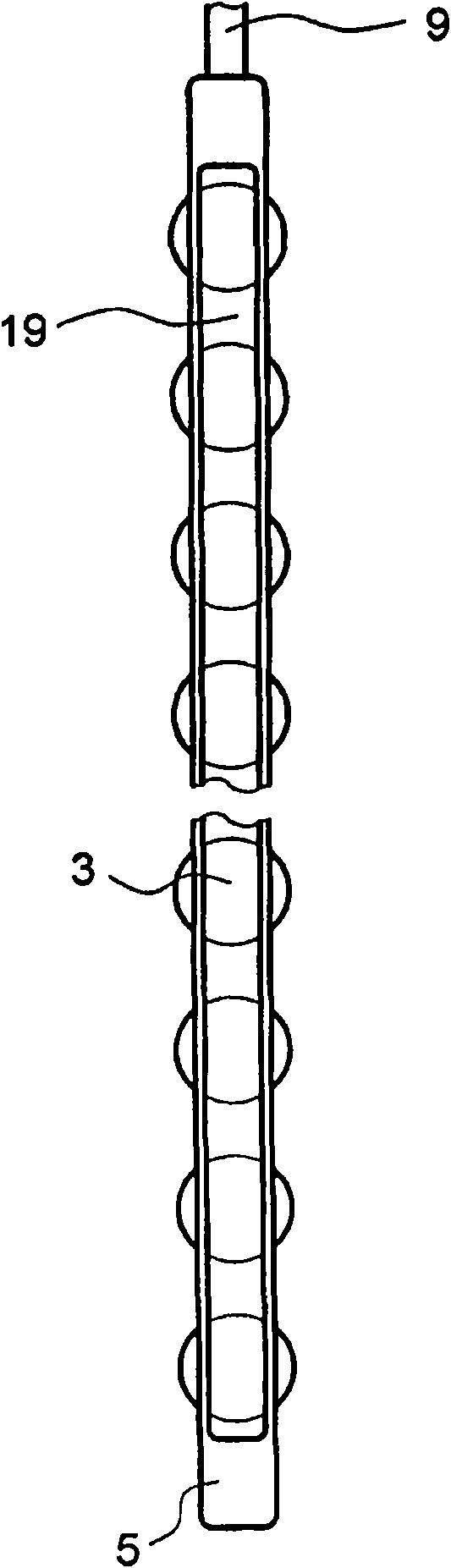

[0099] exist figure 2 Among them, the channel 3 communicates with the raw material header 5 through the hole 13 in the small plate 15 placed at the inlet end of the channel 3 . Channel 3 communicates with product header 7 through catalyst retention screen 17 . The opening 19 at the top of the feedstock header 5 is locked using a removable part or cover 21 .

[0100] exist image 3 , the opening 19 in the feedstock header 5 is unlocked (cover removed) and can be seen extending almost its entire length and giving access to the channel 3 .

[0101] exist Figure 4 Channel 3 in a is not connected. exist Figure 4 In b, the channels 3a-3d are connected two by two by individual flat belts 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com