Sealed micro-pressure pneumatic stirring soybean milk boiling tank

A technology of a slurry cooking tank and a stirring device, which is applied in the field of devices for heating soy milk, can solve the problems that harmful substances cannot be completely killed, it is not boiled in the true sense, and the temperature of soybean protein is not enough, so as to shorten the cooking time. , the effect of shortening the heating time and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

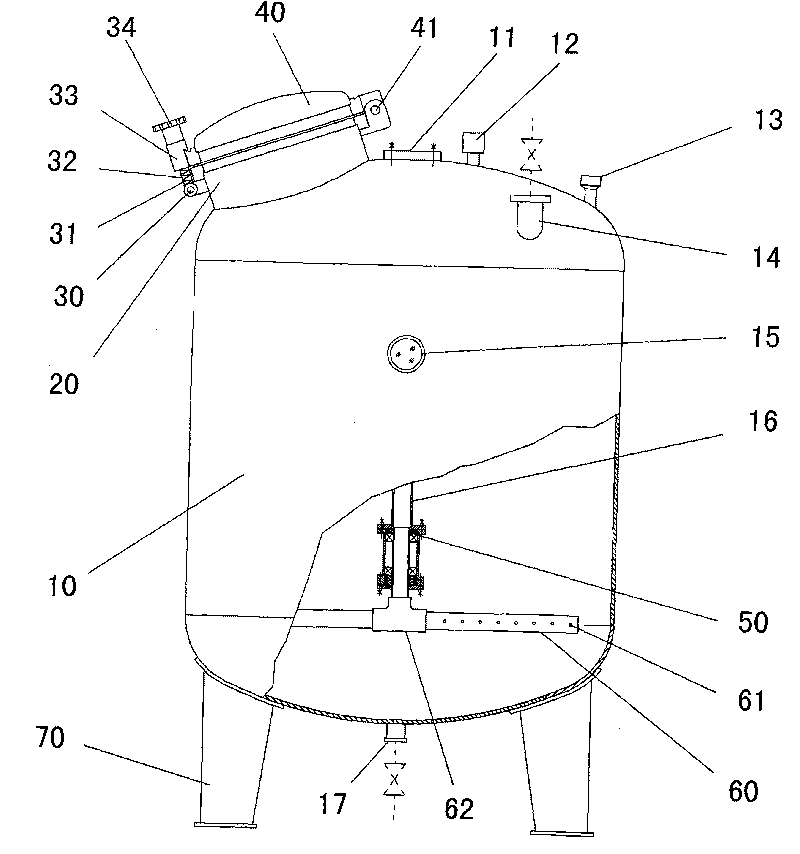

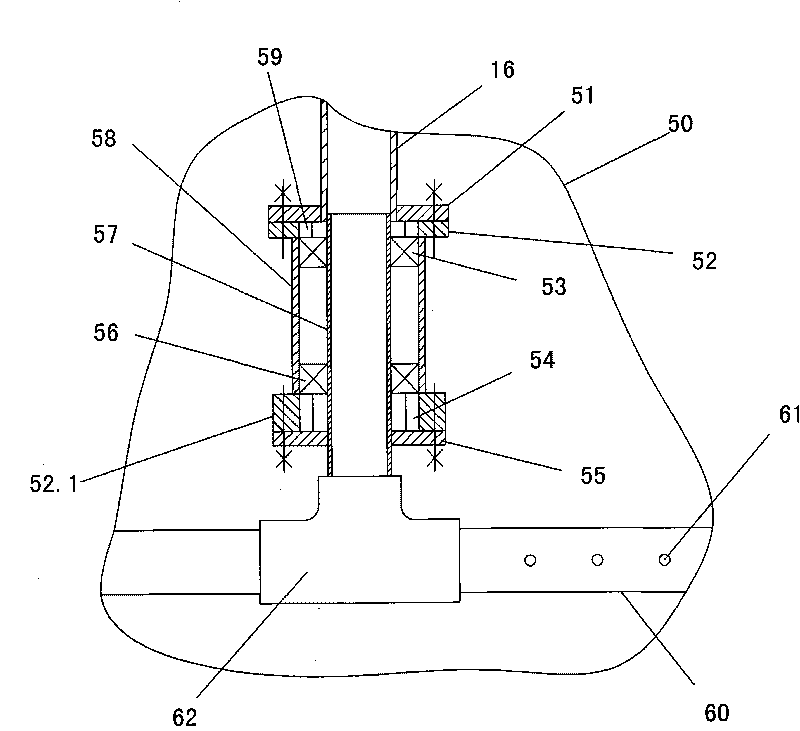

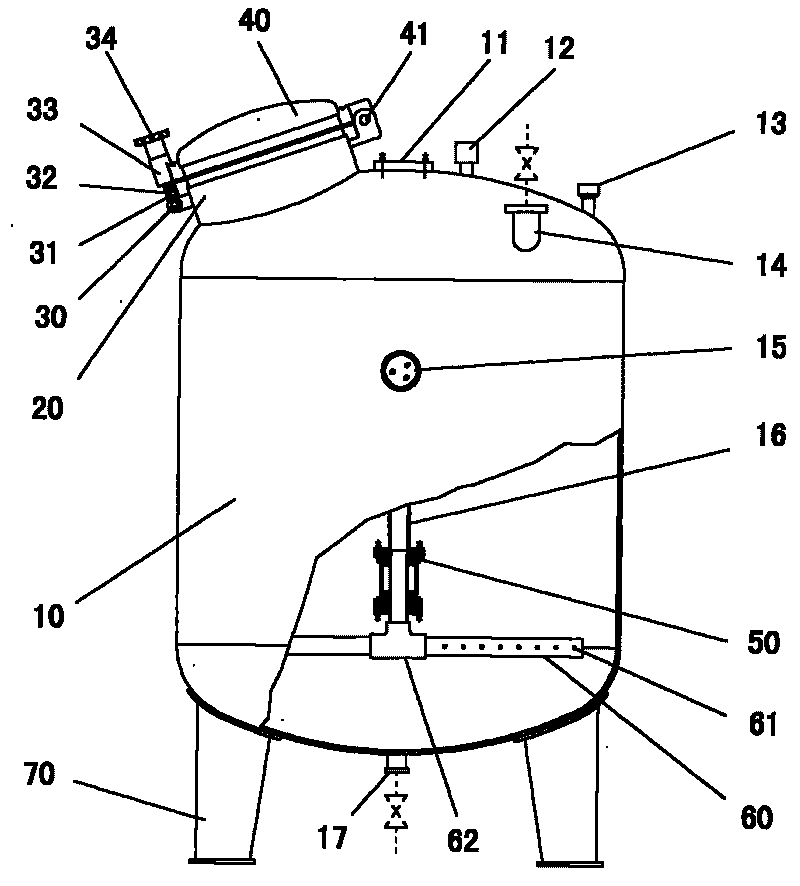

[0009] see figure 1 , the shape of the tank body 10 is a middle cylinder and a hemispherical cylinder with two ends, the inspection port 20 is arranged on the top of the tank body 10, the inspection port 20 and the sealing cover 40 are hinged by a pin 41, and the sealing cover 40 A sealing gasket and a fastening device are arranged between the inspection port 20, and the fastening device includes a rotating shaft 30, a screw rod 32, a slider 33, a spring 31 and a handle 34. The spring 31 and the slider 33 are worn on the screw rod 32, and the handle 34 and the screw rod 32 are threaded, the spring 31 lifts the slider 33 up and connects with the handle 34, the screw rod 32 is hinged on the inspection port 20 through the rotating shaft 30, when working, turn the screw rod 32, and the slider 33 is stuck on the sealing cover 40 Tighten the handle 34 to fasten the sealing cover 40 on the inspection port 20 of the tank body 10 to realize the sealing of the tank body 10. When mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com