Rotary telescopic boom forklift

A technology for telescopic arms and forklift trucks, applied in the direction of lifting devices, etc., can solve the problems that telescopic arms can only work directly in front, poor environmental applicability, and small working range, so as to increase the operating range, good environmental applicability, and work wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

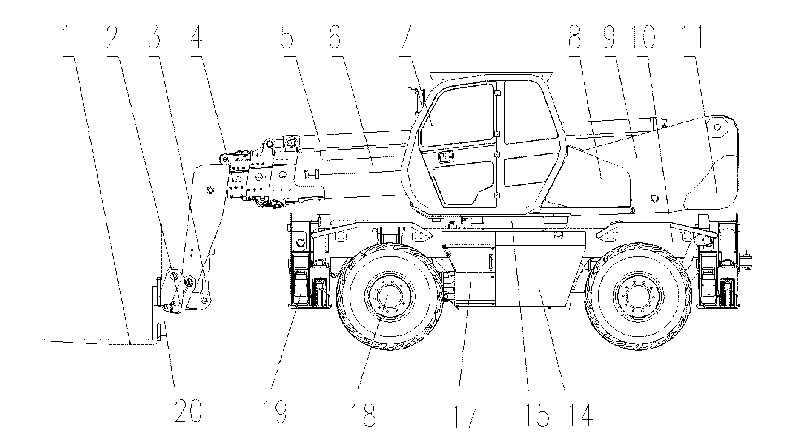

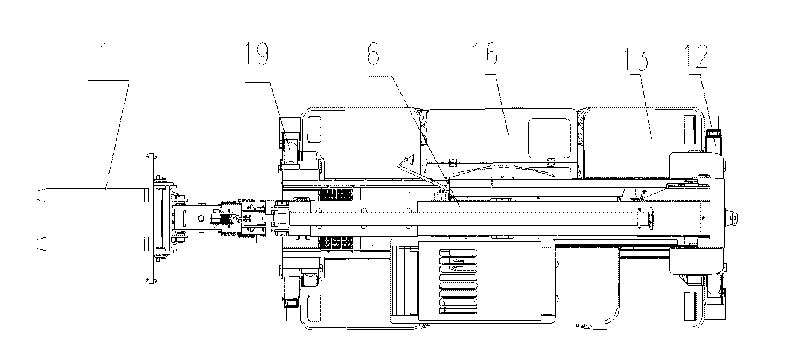

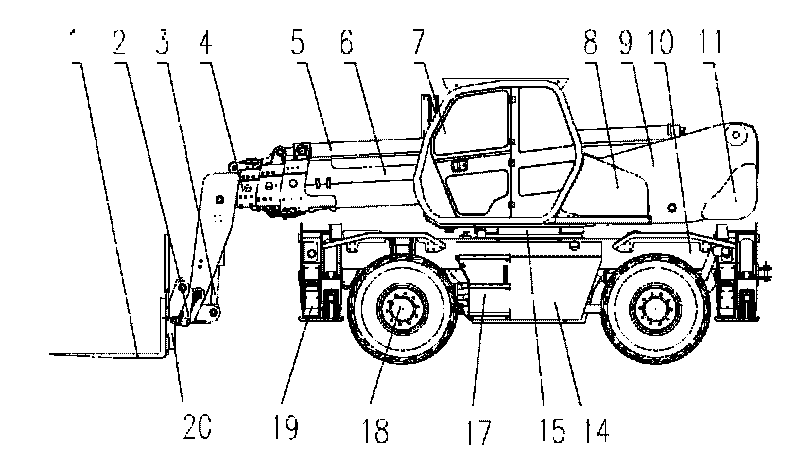

[0010] see figure 1 and figure 2 The front end of the vehicle frame 10 is provided with a front X-shaped leg 19, and the rear end is provided with a rear X-shaped leg 12. When the front X-shaped leg 19 and the rear X-shaped leg 12 support the ground, the whole machine can be supported. off the ground. The right side of the vehicle frame 10 is an engine and a cover 16 , and the left side of the vehicle frame 10 is a fuel tank 14 and a hydraulic oil tank 17 . The front and rear tires 18 are all provided with rain shields 13 . A slewing bearing 15 is arranged above the vehicle frame 10, and a slewing platform 9 is arranged above the slewing bearing 15, and the slewing platform 9 can continuously rotate 360 degrees around the vehicle frame. A driver's cab 7 is installed on the left side of the rotary platform 9, a toolbox 8 is arranged behin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com