Mounting method and mounting device for replacing valve under pressure

A technology with pressure-switching valves and installation devices, which is applied in wellbore/well valve devices, earthwork drilling, wellbore/well components, etc., and can solve the problem of poor sealing of plugs, failure of seating seals, and blocking of plugs Eliminate seat leakage and other problems, achieve the effect of low production and maintenance costs and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

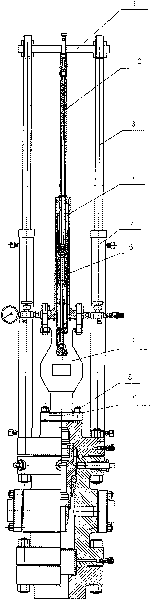

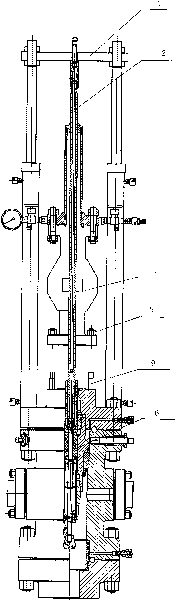

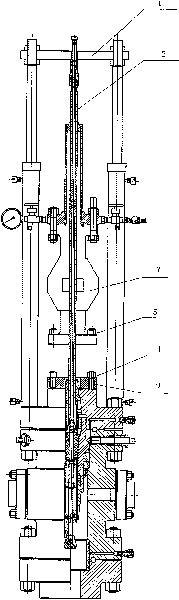

[0026] In a specific embodiment of the present invention, an installation device for a pressure-switching valve is used to implement the installation method for a pressure-switching valve of the present invention, such as figure 1 As shown, it includes a motor, an oil pump, a mounting frame, a clamping plate 11 and a positioning bolt 12; wherein the mounting frame includes a hydraulic cylinder 5, a connecting plate 1 is installed on the liquid rod 3 of the hydraulic cylinder 5, and a plug is installed on the connecting plate 1. The plug liquid rod 2 and the bottom of the plug liquid rod 2 are detachably installed with a plug 6, and the anti-blowout box 4 is covered on the plug liquid rod 2. In order to optimize the structure and force design, the liquid cylinder 5 can be set to two , the two hydraulic cylinders 5 are symmetrically arranged with respect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com