Locating locking fixture for preventing upper and lower static contact baffles in switch cabinet from being opened

A technology for static contacts and switch cabinets, which is applied to the guards/protective devices of switchgear, switchgear components, etc., can solve the problems of exposed high-voltage contacts, personal death, and hidden safety hazards of maintenance personnel, and achieves stable installation and safety. The effect of ensuring personal safety and avoiding electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

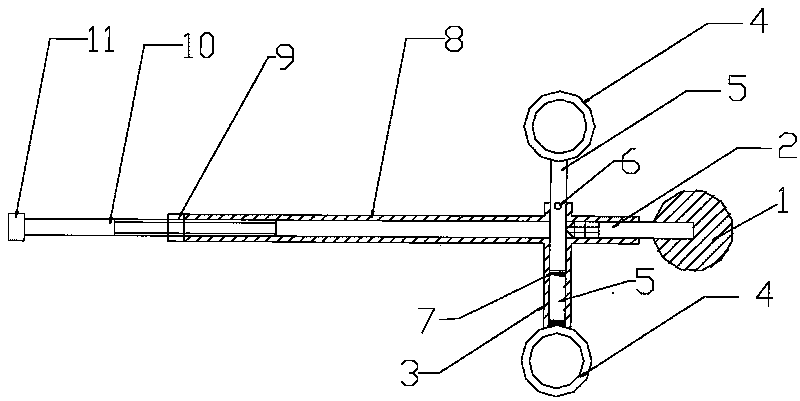

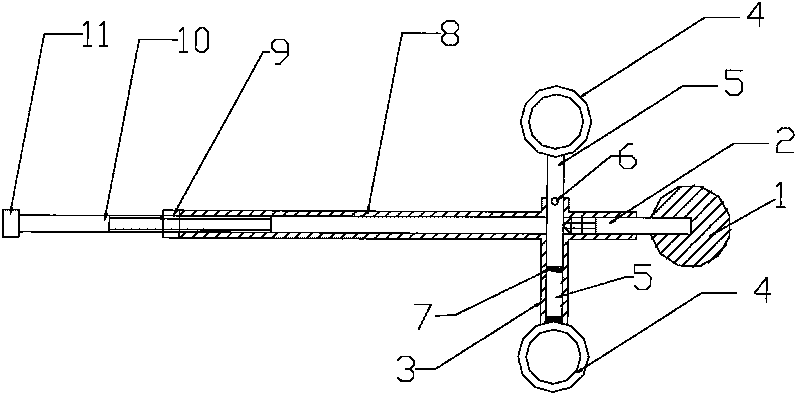

[0009] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

[0010] Embodiment: A positioning locking fixture (see attached drawing) for preventing the opening of the upper and lower static contact baffles in the switch cabinet, it has a rotating stop handle, and the rotating stop handle is an insulating handle 1 made of insulating material and a handle screw 2 connection structure, the handle screw 2 is threadedly connected to the positioning rod 8, the rear part of the positioning rod 8 is provided with a positioning tube 3, the positioning rod 8 and the positioning tube 3 are connected as one, and the positioning tube 3 is inserted with two relative ferrule adjustment screws 5. One of the ferrule adjusting screw 5 is covered with a spring 7, and the other ferrule adjusting screw 5 is provided with a stop pin 6. Each ferrule adjusting screw 5 is connected to an adjusting ferrule 4, and the front end of the positioning rod 8 A fixing nut 9 is provided and an adjusting screw 10 is inserted therein. The fixing nut 9 is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com