Current vector control device and control method of power return

A technology of current vector and control device, applied in AC motor control, control system, irreversible DC power input conversion into AC power output and other directions, can solve the problem of difficulty in ensuring the accuracy and quality of feedback current control, system dynamic performance and anti-interference Poor performance, affecting the system control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

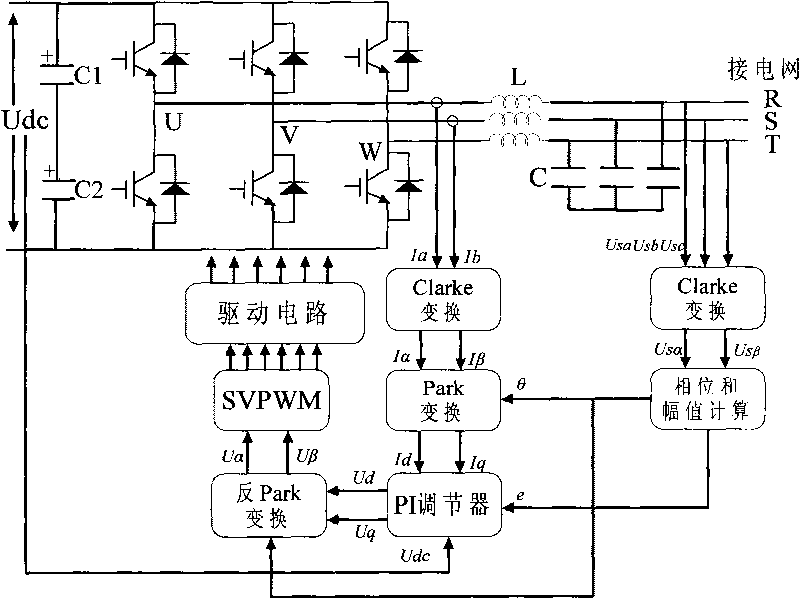

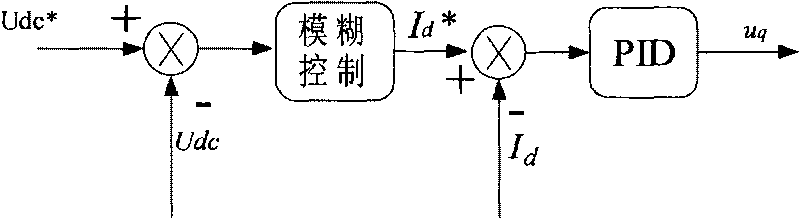

[0038] Embodiment 1: refer to Figure 1~3 . The current vector control device for energy feedback includes an inverter circuit, the output voltage U, V, W of the inverter circuit is respectively connected to one end of the reactor L, and the three-phase voltage R, S, T of the power grid is respectively connected to the reactor L The other end is connected, and the high-frequency filter capacitor C is connected to the connection between the filter reactor L and the three-phase voltage R, S, and T of the grid. The current vector control device also includes a clarke transformation module, a phase and amplitude calculation module, and a Park Transformation module, PI regulator, inverse Park transformation module, space voltage vector modulation module and drive circuit, the U of the three-phase voltage of the power grid sa , U sb and U sc The voltage output terminals of the Clarke transformation module are respectively connected with the Clarke transformation module, and the o...

Embodiment 2

[0039] Embodiment 2: refer to Figure 1~4 . The current vector control method of energy feedback, its whole processing sampling includes the following steps:

[0040] 1) U sa , U sb and U sc is the three-phase voltage of the power grid, and after Clarke transformation, U in the static coordinate system is obtained sα and U sβ :

[0041] U sα U sβ = 2 3 1 - 1 2 - 1 2 0 ...

Embodiment 3

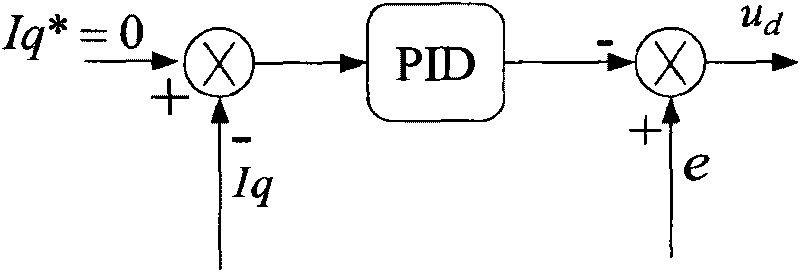

[0060] Embodiment 3: refer to Figure 4 . Because the reactor ignores the internal resistance, the current lags the voltage by 90°, where is the inverter output voltage, is the grid voltage. The d-axis component of the voltage output by the inverter U d and When equal, I q =0; at this time by adjusting U q , you can control the I d size. This enables independent control of active and reactive currents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com