Large deflection loose tube compensation joint

A technology for compensating joints and large deflection, which is applied in the direction of expansion compensation devices for pipes/pipe joints/fittings, pipelines, adjustable connections, etc., which can solve the problems of large material consumption, easy dripping, and small compensation amount of wave compensators And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

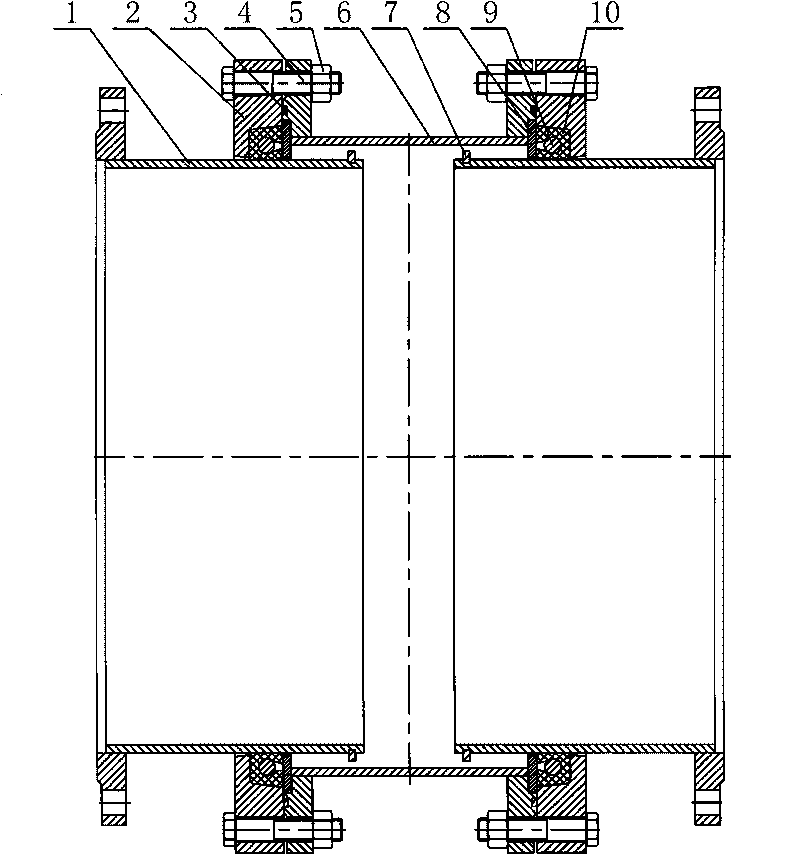

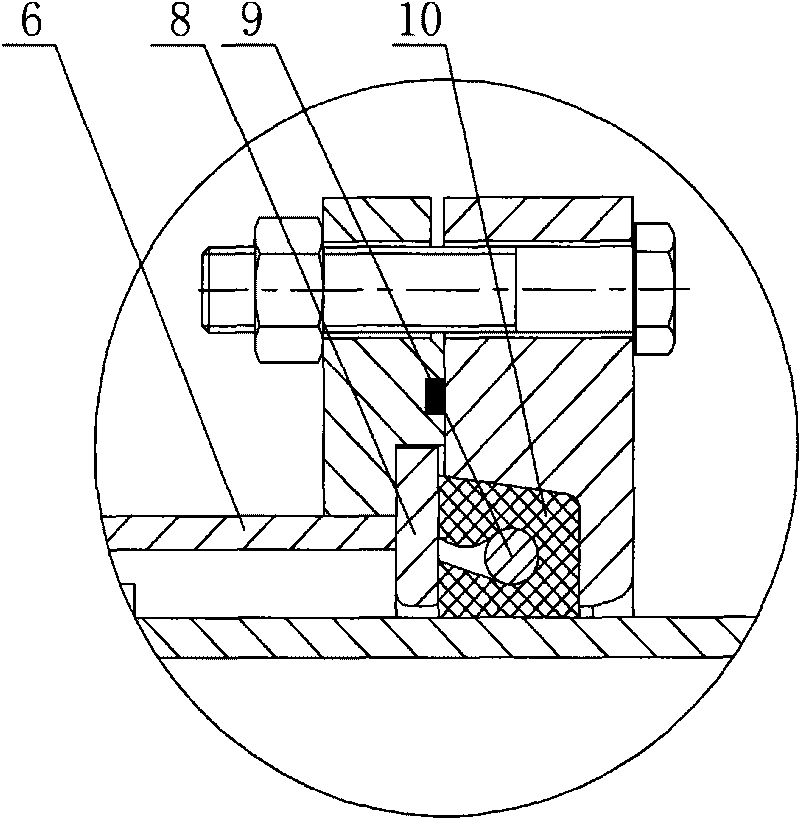

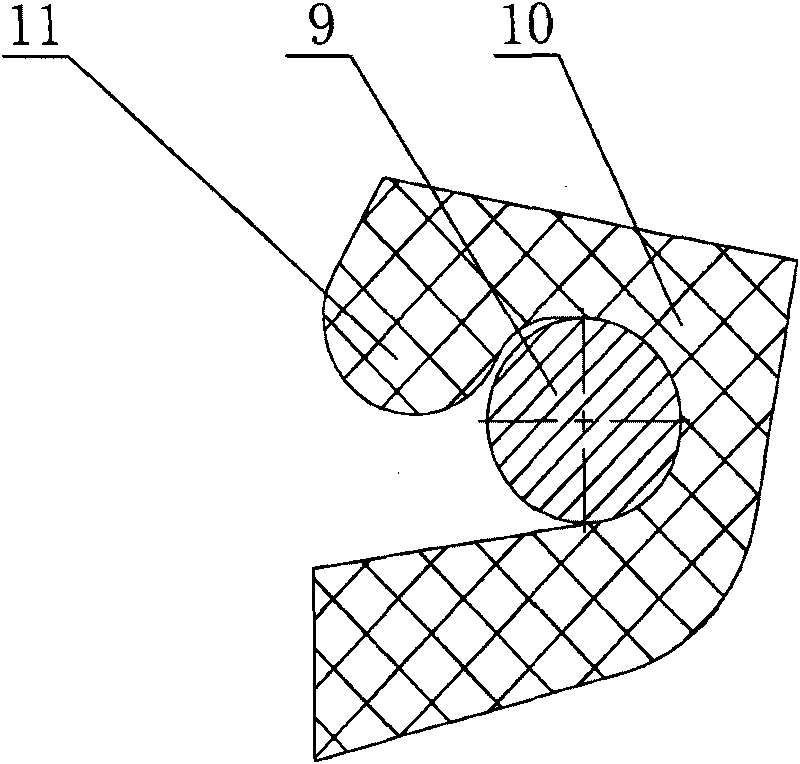

[0012] Such as figure 1 , 2 As shown, a large deflection loose sleeve compensating joint according to the present invention includes a cylindrical body 6, and the inside of the body 6 passes through two movable short pipes 1 with flanges, and the flanges are located at the ends of the short pipes 1 Both ends; the connection ends on both sides of the body 6 are respectively connected to a gland with bolts 4 and tightened with nuts 5. A ring of sealing strips 3 is provided on the connection surface between the body 6 and the gland 2; the inner sides of the two ends of the body 6 are respectively A retaining ring 8 is installed, and the retaining ring 8 is sleeved on the outside of the short pipe 1, and a limit block 7 is installed on the short pipe 1, and the limit block 7 interferes with the retaining ring 8, thereby preventing the short pipe from 1 slips off from the body 6; a sealing ring 10 is installed between the retaining ring 8 and the gland 2, the sealing ring 10 is U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com