Mechanical property test method for fabric and textile structural composite materials

A technology of composite materials and fiber fabrics, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficult performance evaluation of fiber fabrics and textile structure composite materials, and achieve the effect of accurate force performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

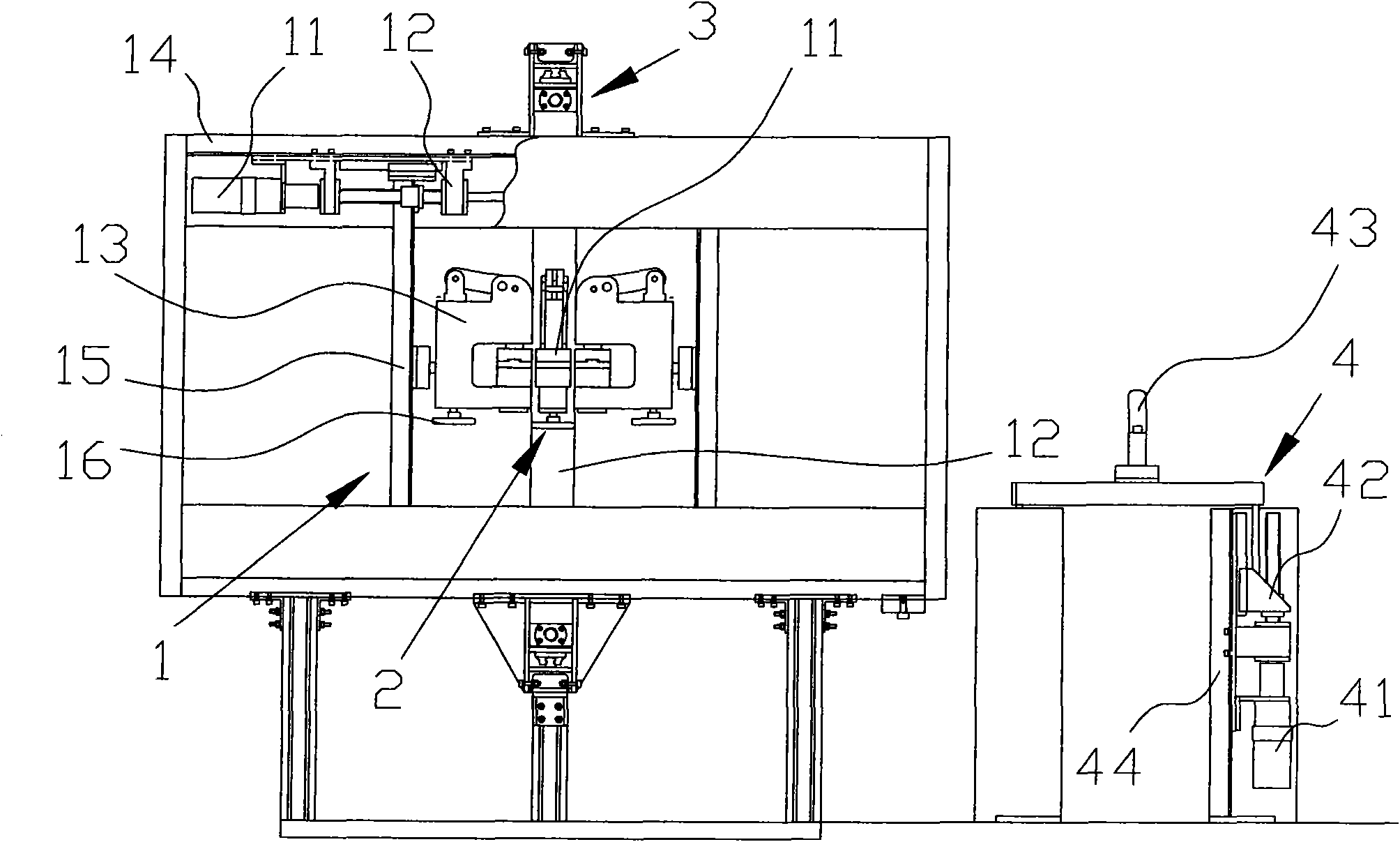

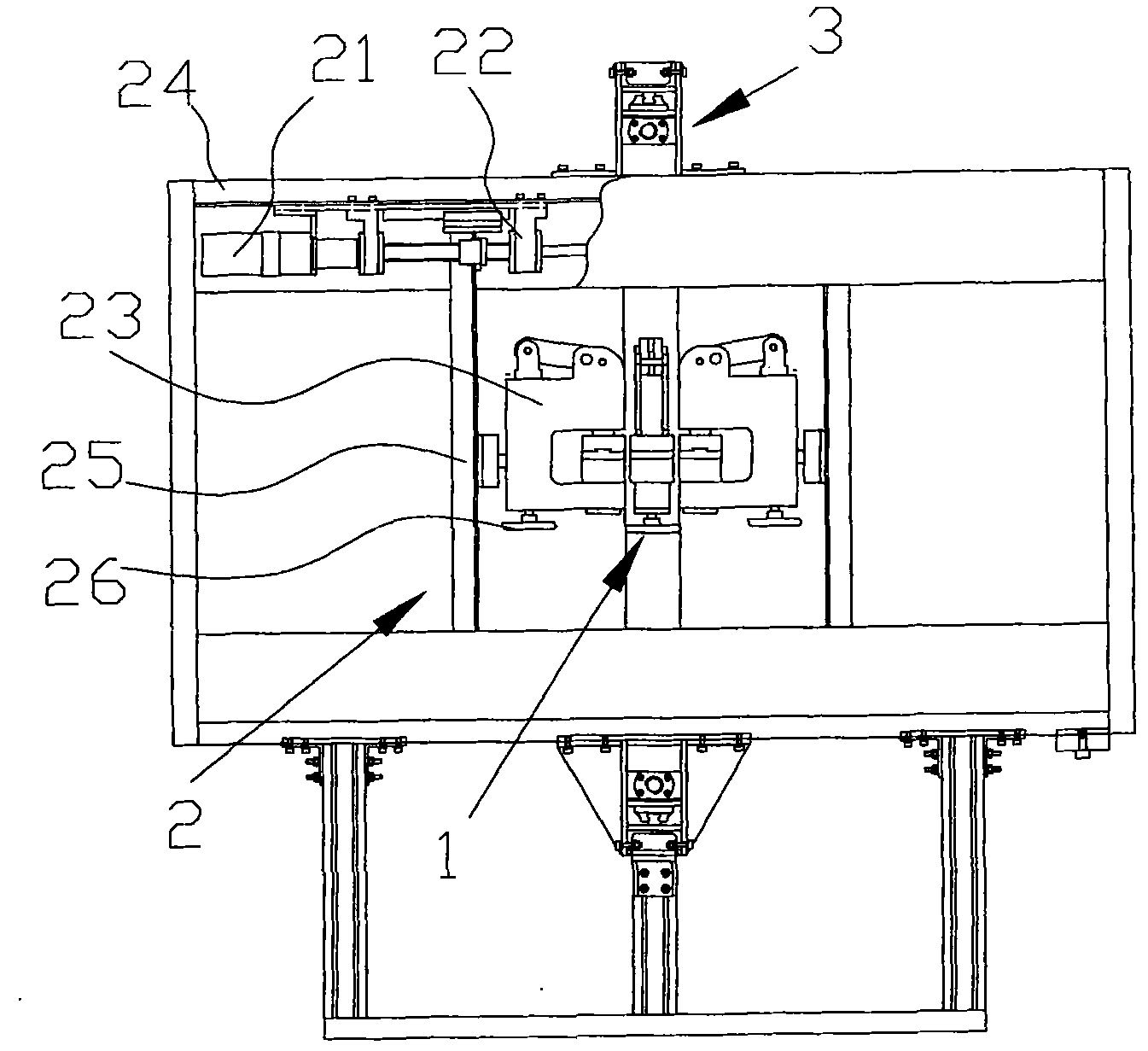

[0018] like figure 1 As shown, the test device adopted in the present invention includes: X-axis tension-compression unit 1, Y-axis tension-compression unit 2, vertical bursting unit 4 and digital speckle (DSCM) test unit 3; wherein, X-axis tension-compression unit 1 is used For the material to be tested in the X-axis (in figure 1 In the left and right directions) tension and compression; Y-axis tension and compression unit 2 is used to carry out the Y-axis (in the figure 1 (middle is the front-to-back direction) tension and compression; the vertical bursting unit 4 is used when the material to be tested is stretched along the X-axis and the Y-axis, and the material to be tested is applied along the plane perpendicular to the X-axis and the Y-axis. The abutting force in the direction (that is, the direction that forms an angle of 90° with the plane of the X-axis and the Y-axis); the digital speckle (DSCM) test unit 3 is used to measure the deformation process of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com