Spectacles, telescopic spectacles and stereoscopic vision spectacle frame components

A stereoscopic vision and spectacle frame technology, applied in telescopes, glasses/goggles, optical components, etc., can solve problems such as unfavorable production, inconvenient use, complex production processes, etc., to prevent external impact, avoid relative motion, and expand functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The purpose is to use the principle of magnetic attraction to provide eyewear manufacturers with a simple process and flexible assembly eyewear system; at the same time, it also provides users with a multi-purpose eyewear system that can be flexibly assembled and disassembled and freely matched.

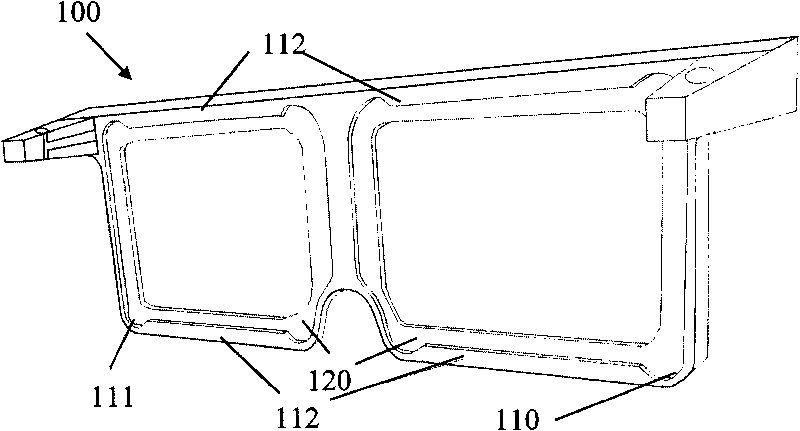

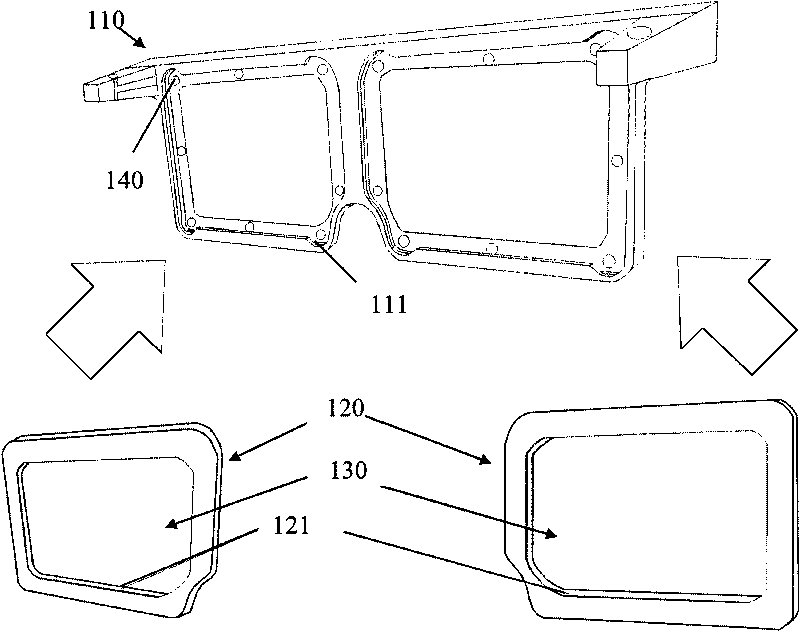

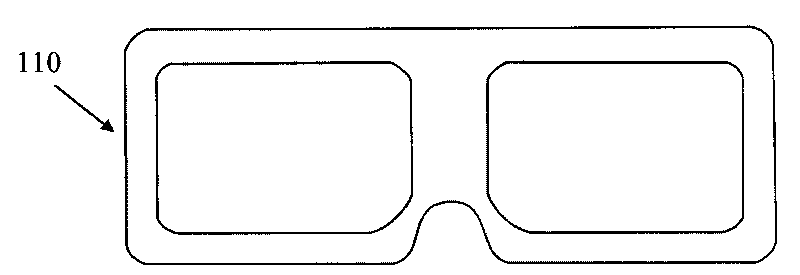

[0045] see also figure 1 , figure 2 , is an ordinary spectacle frame assembly 100, including a frame mother frame 110 and a lens sub-frame 120, wherein:

[0046] The lens sub-frame 120 is provided with inner grooves 121, in which the lenses 130 are respectively embedded;

[0047] The mother frame 110 of the mirror frame offers an inner groove 111, which is inserted into the lens sub-frame 120; a guide baffle 112 is also arranged outside the inner groove 111, so that the lens sub-frame 120 is fixed in the groove 111 of the mother frame of the mirror frame, and will not fall inward or outward;

[0048] At the same time, a magnetic attraction structure is provided at the junc...

Embodiment 2

[0063] The aim is to provide users with an interchangeable eyepiece, objective lens, adjustable telephoto distance, and a multi-purpose telescopic system that is easy to wear.

[0064] see Figure 8 , the telescope adopts Galileo optical system or Kepler optical system, and its telescope frame assembly 200 includes a mirror frame mother frame 210, an eyepiece frame 220 and an objective mirror seat 230, wherein: the eyepiece frame 220 has an inner groove of the eyepiece , wherein the eyepiece (concave lens or convex lens) 240 is embedded; the objective mirror seat 230 is a cylindrical structure, the rear end is provided with a mounting plate 231, and the front end is provided with an inner groove 232, wherein the objective lens (convex lens or plano-convex lens) 250 is embedded; the frame mother frame 210 is provided with double inner grooves 211, which are respectively inserted into the eyepiece mirror frame 220 and the objective mirror holder mounting plate 231. Simultaneous...

Embodiment 3

[0068] The purpose is to provide users with a kind of multi-functional stereoscopic video glasses that are easy to operate, multi-functional, and can be used to watch stereoscopic images in left and right formats, stereoscopic images in top and bottom formats, stereoscopic photo negatives, stereoscopic images, etc. system.

[0069] see Figure 9 , which is a stereoscopic video glasses frame assembly 300, comprising a frame mother frame 310, an eyepiece holder 320 and an objective mirror holder 330, wherein:

[0070] The eyepiece holder 320 is a cylindrical structure, the bottom is provided with a mounting plate 321, the side is provided with a ring buckle (external protrusion) 322, and a flat mirror (eyepiece) 340 is embedded inside, and its mirror surface is 45 degrees from the bottom surface of the eyepiece holder 320. bevel.

[0071] The objective mirror seat 330 is a cylindrical hemispherical structure, and the inner side is provided with an annular draw-in groove (inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com