Prorated type brake master cylinder

A proportional distribution, brake master cylinder technology, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problem of insufficient rear wheel braking force, affecting the braking effect of the front wheel, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

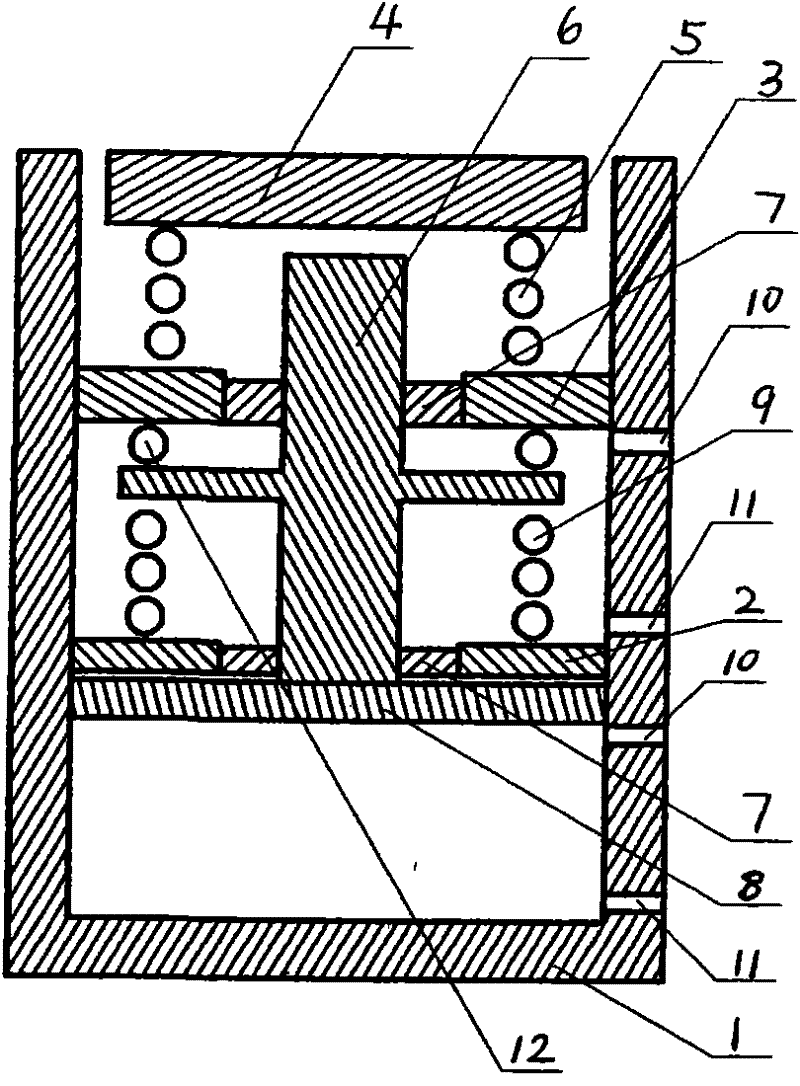

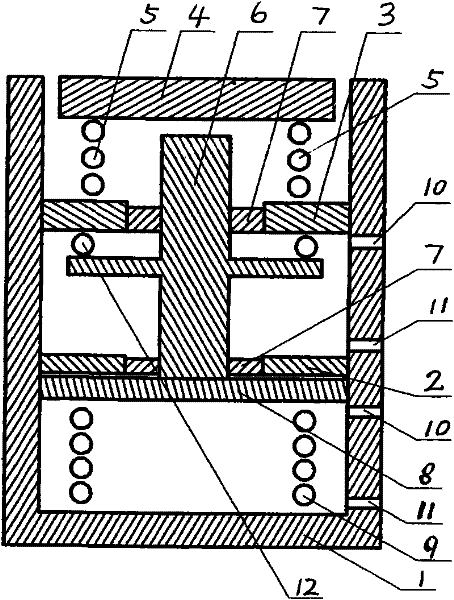

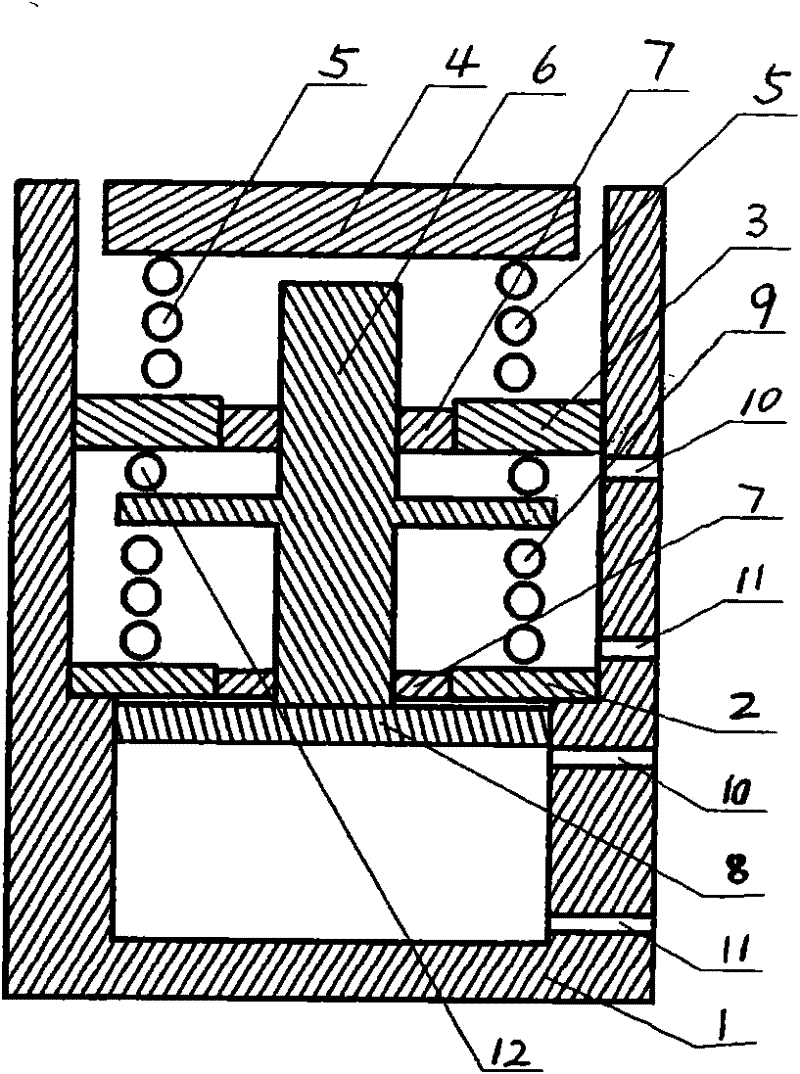

[0012] The oil outlet passage 11 of the first moving working chamber part of the proportional distribution type brake master cylinder of the present invention is connected with the front wheel brake wheel cylinder of the motor vehicle, and the oil outlet passage 11 of the driven working chamber part is connected with the rear wheel brake cylinder of the motor vehicle. Wheel cylinder connection. When the motor vehicle brakes, the ejector rod pushes the active push rod 4 to move forward, and the main component spring 5 drives the first-moving piston pair 3 to move forward, and the hydraulic oil in the first-moving working chamber is compressed to enter the front wheel brake wheel cylinder. Make the brake friction plate contact with the brake drum or the brake disc, at this moment the main force component spring 5 starts to compress. The active push rod 4 continues to move forward, pushes the driven push rod 6 and the driven piston 8 to move forward, and compresses the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com