Aluminum alloy lifting energy-saving sliding door

An aluminum alloy, door leaf technology, applied in windows/doors, door/window accessories, building components, etc., can solve the problems of wear and tear on the surface of the sealing tops, failure to achieve thermal insulation and broken bridges, and inability to ensure the safety of large open doors, etc. Achieve the effect of prolonging the service life, opening flexibly, and solving the problems of crack ventilation and anti-theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings.

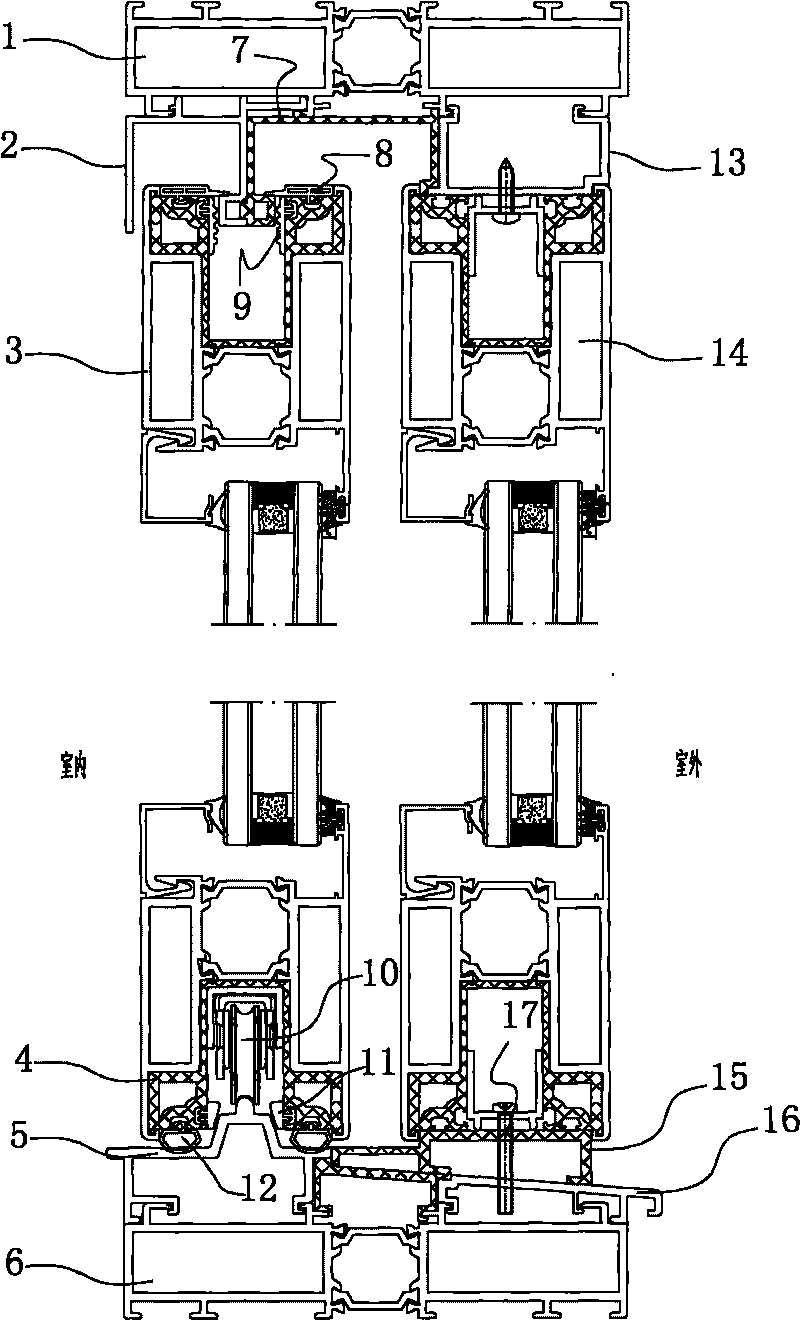

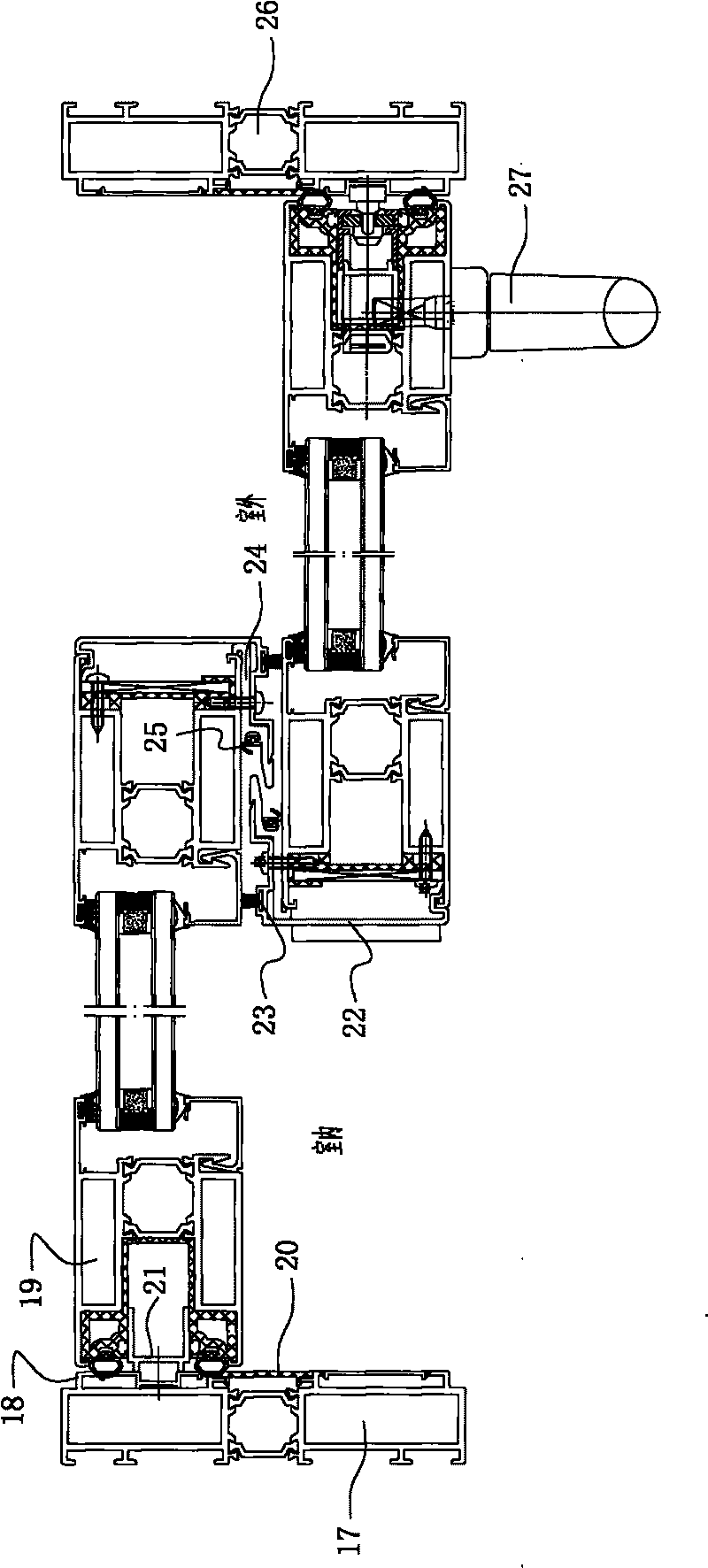

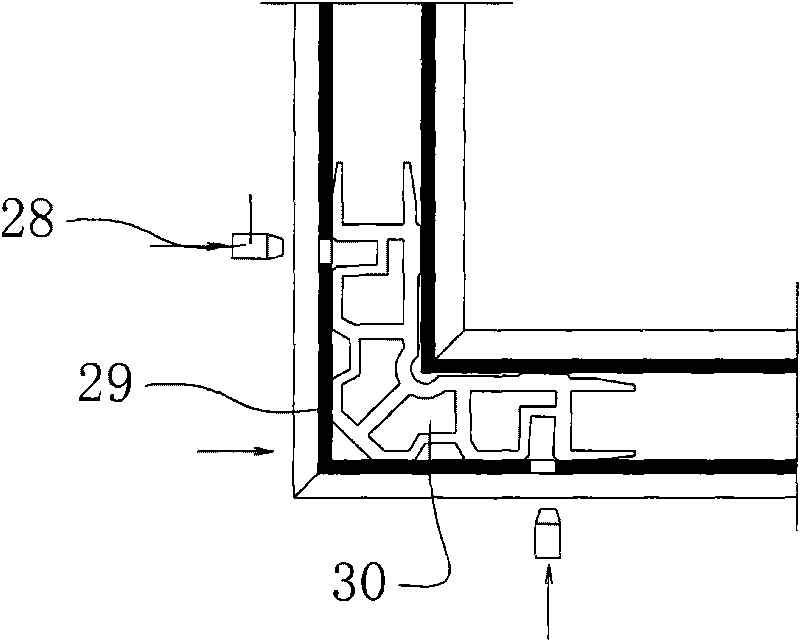

[0019] Such as figure 1 An aluminum alloy lifting sliding energy-saving door is shown. The sliding energy-saving door includes a plastic door frame and two door leaves. The plastic door frame is composed of two frame materials combined with heat insulation through strips. The fan frame of the door leaf is composed of two frame materials combined with heat insulation through strips. The two door leaves are a fixed door leaf 14 and a sliding door leaf 3, and the fixed door leaf 14 is arranged outside the sliding door leaf 3. The plastic door frame and the fan frame form three cavities or multiple cavities so that the profile has a very good thermal insulation effect.

[0020] Such as figure 1 As shown, the plastic door frame is composed of a plastic upper frame 1, a plastic lower frame 6, a plastic left frame 17 and a plastic right frame 26. The plastic upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com