Fixing device of optical detector

An optical detector and fixing device technology, applied in measuring devices, scientific instruments, material analysis by optical means, etc., can solve the problems of low detection accuracy and easy shaking of various components, so as to improve detection accuracy, reduce shaking, enhance The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

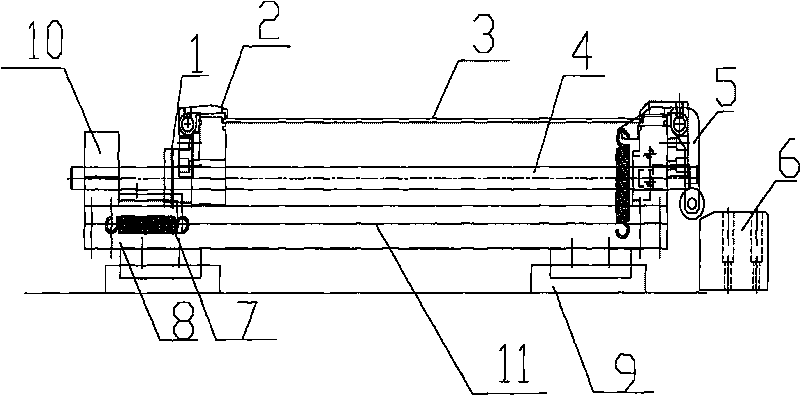

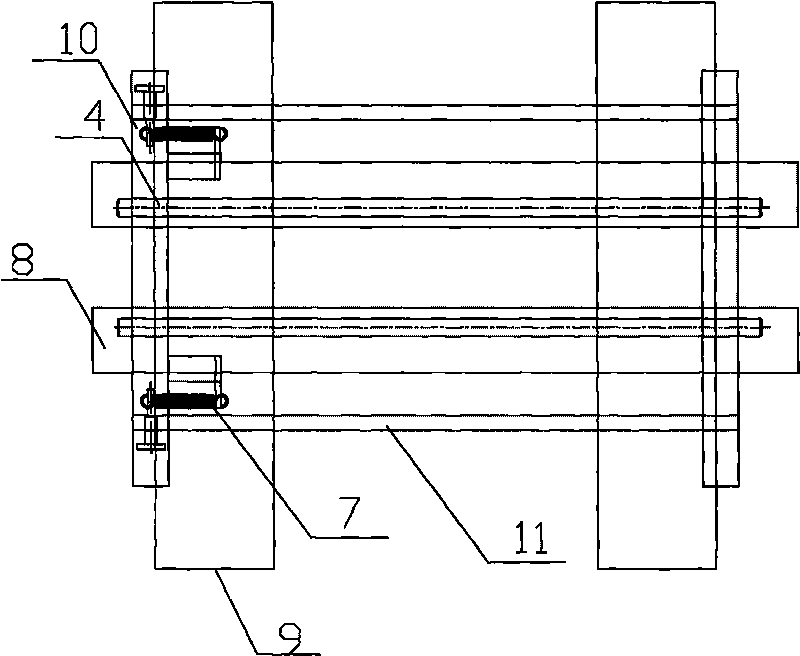

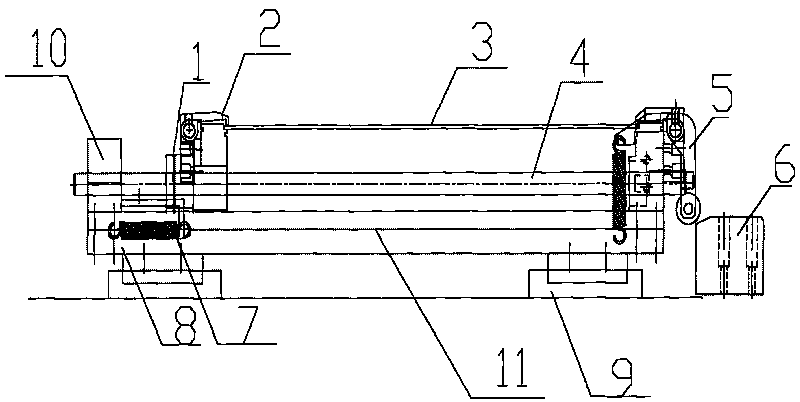

[0014] like figure 1 and figure 2 Shown are a schematic structural view and a top view of the optical detector including the fixing device of the present invention, respectively.

[0015] The fixing device of the optical detector of the present invention includes two parallel slide rails 8 positioned on the base 9 and perpendicular to the base 9, a fixture body 1 and a fixture backstage located on the parallel slide rails 8 and connected by a long connecting rod 4 and a guide rod 11 10. The pressure jaw 2 for fixing the PCB board 3 on the clamp body 1, the connecting rod 5 on the clamp body 1 and the blocking seat 6 located at the front end of the optical detector, wherein, between the clamp backstage 10 and the guide rod 11, there are Extension spring 7. The extension spring 7 is parallel to the guide rod 11 and is fixed between the fixture backstage 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com