Hollow core rod used for planetary rolling mill

A planetary rolling mill, hollow core technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of wasting pipes, increasing production costs, and low service life of mandrels, and achieving the effect of smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

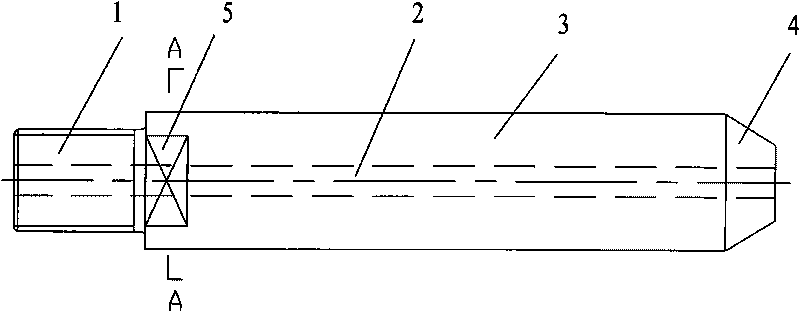

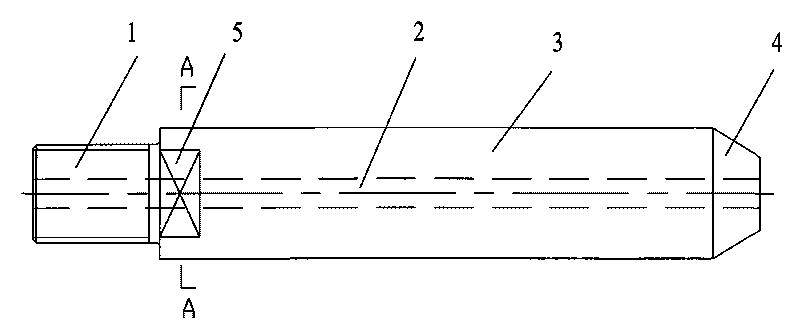

[0009] A hollow mandrel rod for a planetary rolling mill, including a rod body 3, a threaded section 1 located at the left end of the rod body 3, and a tapered section 4 located at the right end of the rod body 3. The rod body 3 is also tapered, so that the left end of the rod body 3 is larger than The right end of rod body 3.

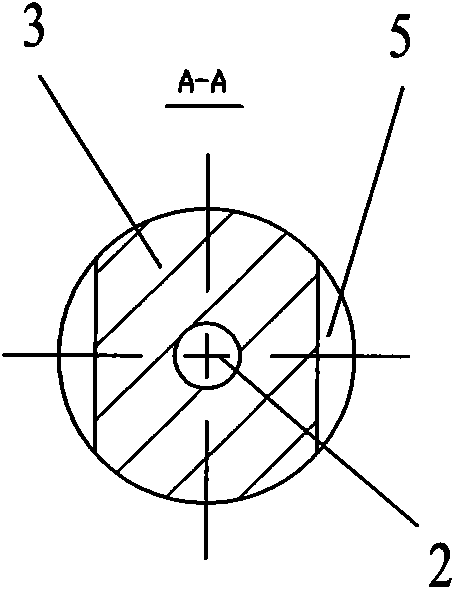

[0010] Through holes 2 communicating with each other and located on the same axis are provided in the rod body 3 , the threaded section 1 and the tapered section 4 . Two planes 5 are provided on the outer surface of the rod body 3 close to the threaded section 1 , and the two planes 5 are parallel to each other and symmetrical to the axis of the rod body 3 .

[0011] The taper of the rod body 3 is 150:0.08. The material of the hollow mandrel is H13, and the hardness of the hollow mandrel is HRC53-55.

[0012] Through the above process innovation, the service life of a mandrel has been greatly improved. Each mandrel can be rolled 8 to 10 tons at a tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com