Cone pulley plate mechanism on water tank wire-drawing machine

A water tank wire drawing machine and the technology of the tower wheel, which is applied in the wire drawing field in the production of metal products, can solve the problems of scrapping and irreparable tower wheels, etc., and achieve the effects of ensuring the quality of wire drawing, overcoming irreparability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

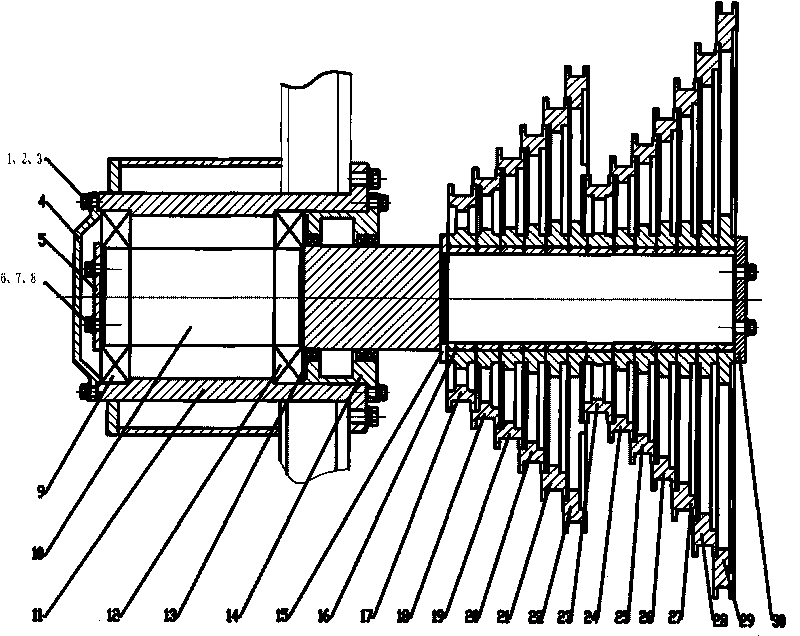

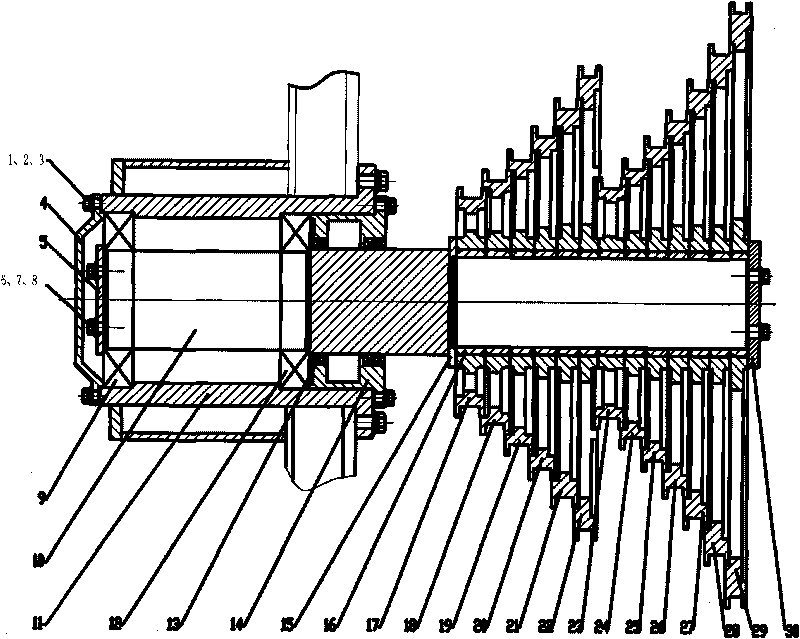

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0009] Such as figure 1 As shown, it includes: bolt 1, flat washer 2, spring washer 3, tower wheel sleeve cover 4, bearing pressure plate 5, flat washer 6, spring washer 7, bolt 8, first bearing 9, tower wheel shaft 10, Movable tower wheel bearing seat 11, second bearing 12, oil seal 13, movable tower wheel shaft oil seal seat 14, tower wheel spacer 15, copper sleeve 16, first tower wheel 17, second tower wheel 18, The third tower wheel 19, the fourth tower wheel 20, the fifth tower wheel 21, the sixth tower wheel 22, the seventh tower wheel 23, the eighth tower wheel 24, the ninth tower wheel 25, the sixth tower wheel The tenth tower wheel piece 26, the eleventh tower wheel piece 27, the twelfth tower wheel piece 28, the thirteenth tower wheel piece 29, the tower wheel piece shaft end pressure plate 30.

[0010] In the present invention, the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com