Roll paper on-line humidifying device

A technology of humidifying device and web, which is applied in printing, printing machines, general parts of printing machinery, etc. It can solve the problems of inconsistent water content, waste of the whole roll of paper, long time, etc., and achieve controllable humidification degree and humidification quality Good, high humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

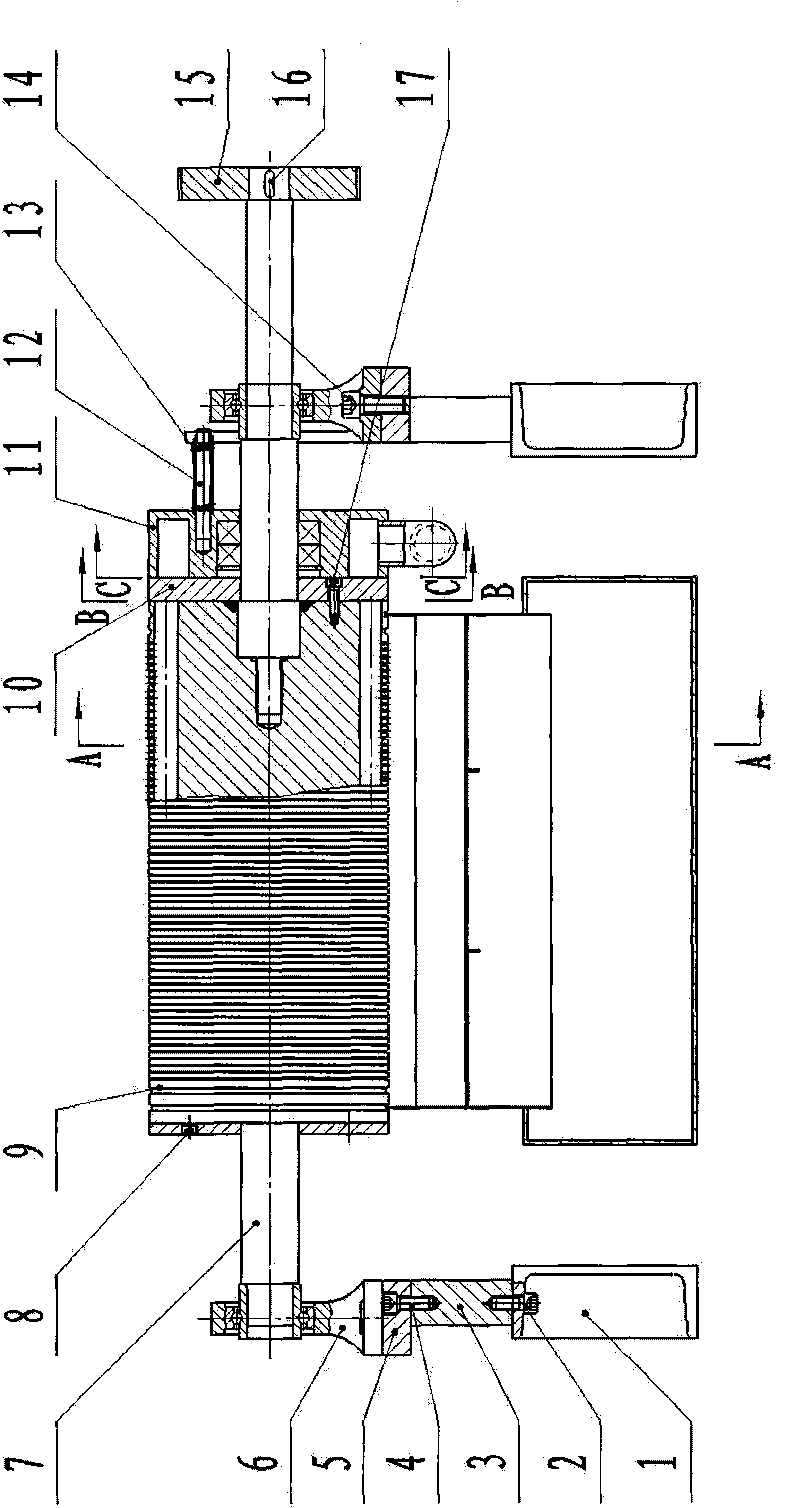

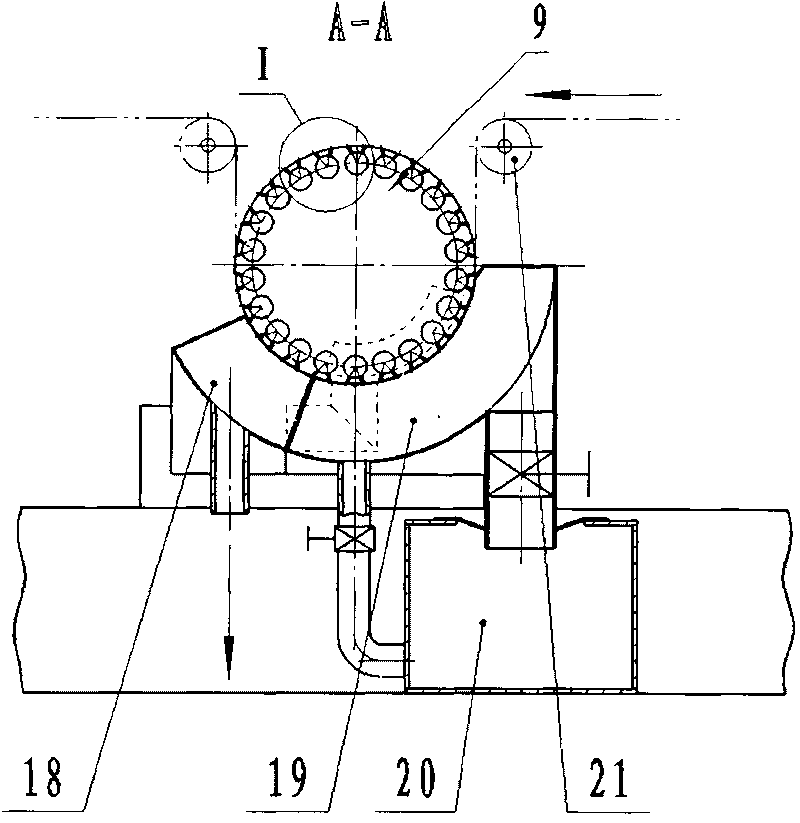

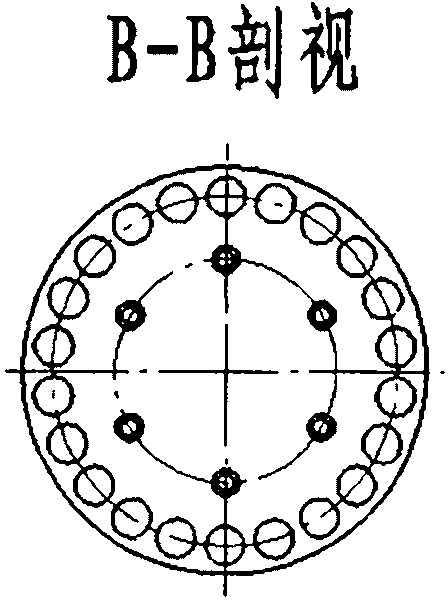

[0019] figure 1 The humidifying roller of the web online humidifying device shown is composed of a left end plate left end shaft assembly 7, a cylinder body 9, a right end plate right end shaft assembly 10 connected by screws 8, 17, a left end plate left end shaft assembly 7 and a right end plate right end The shaft assemblies 10 are mounted on the frame 1 through bearings, bearing blocks 6, support plates 5, base 3 and screws 2, 4, 14, and the right end shaft assembly 10 is connected with a key 16 to rotate synchronously with the printing production line. The belt pulley 15, the cylinder 9 of the humidifying roller is made of a cylinder, in which 22 axially arranged holes are drilled as air suction channels, and these air suction channels are densely distributed on the cylinder 9. The hole communicates with the outside of the cylinder 9, such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com