Round intelligent fuel cell humidifier and humidifying method thereof

A fuel cell and fuel cell stack technology, applied in the field of humidification system, can solve the problems of insufficient intelligent humidification adjustment of humidifier, increased cost of fuel cell system, inability to adjust the humidity of fuel gas, etc., so as to improve humidification effect and improve humidification. Efficiency, Conducive to Stabilization and Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

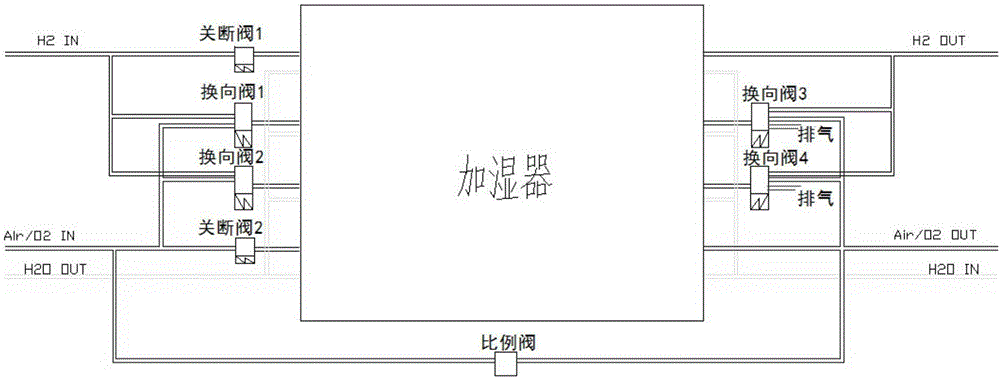

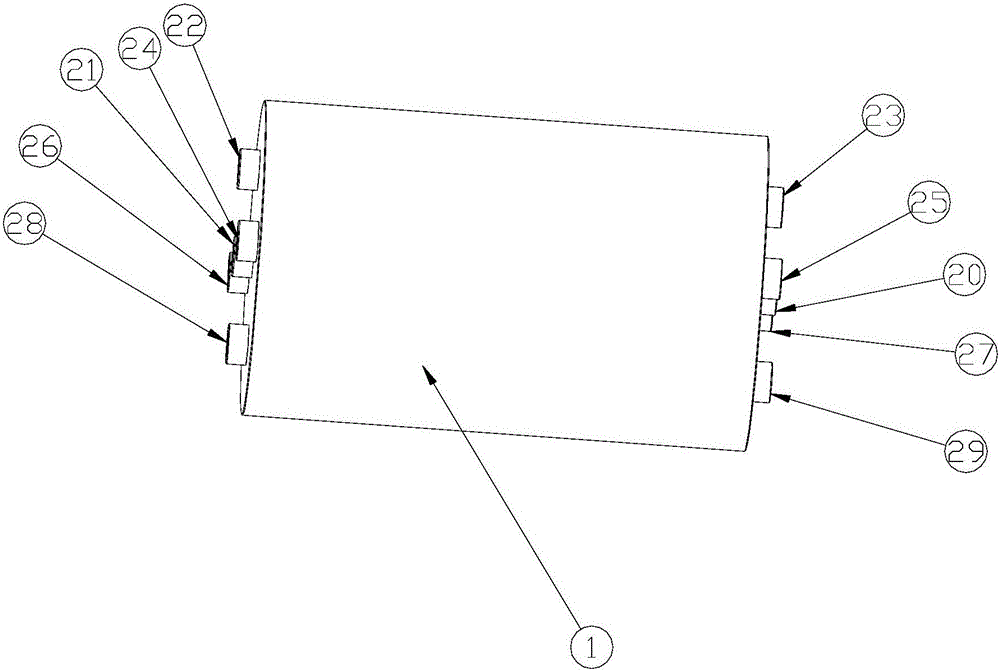

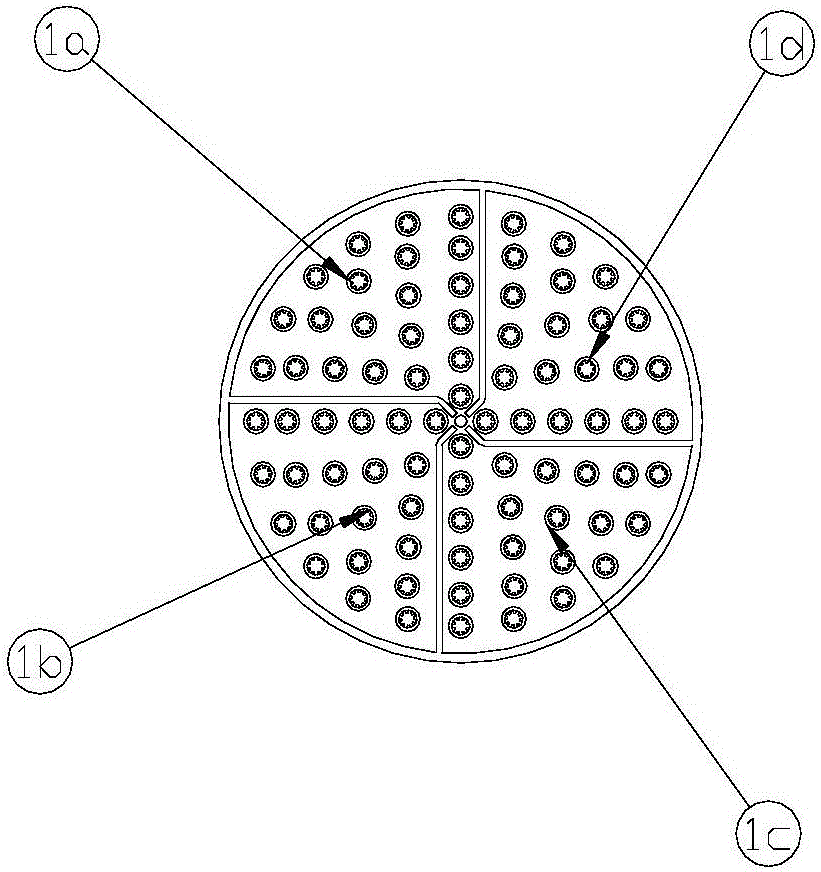

[0042] Embodiment: a kind of circular intelligent fuel cell humidifier, such as figure 1 shown. It includes a cylindrical humidifier main body 1, and four humidification areas are arranged in the humidifier main body 1 along the circumference of the axis, such as figure 2 As shown, the A humidification area 1a is the fuel gas humidification area, B and C humidification areas 1b and 1c are the common humidification areas for the fuel gas and oxidant gas, and the D humidification area 1d is the oxidant gas humidification area. The end plate of the device is sealed, and the axis of the two end plates is also provided with a humidification medium inlet 20 and a humidification medium outlet 21. The humidification medium flow channels in each humidification area share the humidification medium inlet 20 and the humidification medium outlet 21. A humidification Both ends of area 1a are provided with dry fuel gas inlet 22 and wet fuel gas outlet 23, both ends of D humidification area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com