Low-noise electromagnetic valve

A solenoid valve, low noise technology, applied in the field of solenoid valve, can solve the problems of slow volume, complex fluid path, complex process, etc., to achieve the effect of rapid opening and closing, broad application prospects, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

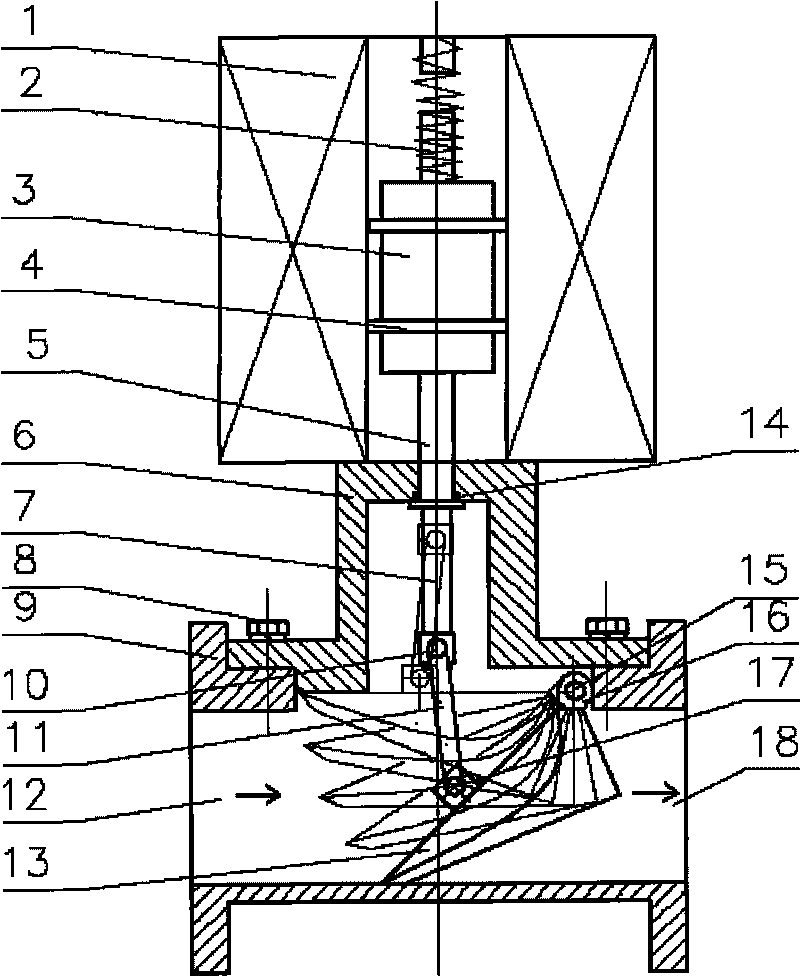

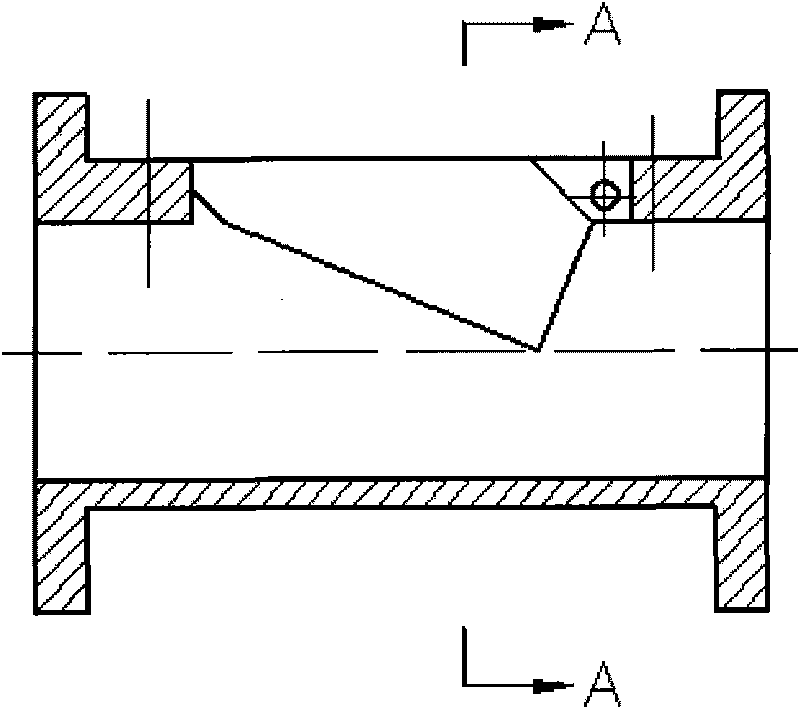

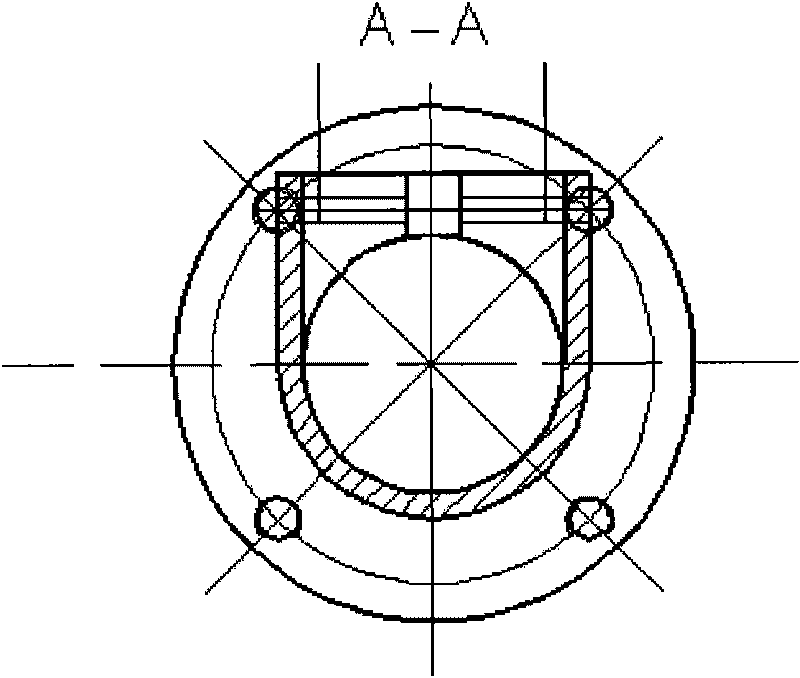

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] combine Figure 1-Figure 4 , the solenoid valve is mainly composed of coil 1, spring 2, armature 3, bearing ring 4, push rod 5, upper cover 6, pull rod 7, connecting bolt 8, connecting flange 9, connecting block 10, pull plate 11, inlet 12, Spool 13, sealing ring 14, shaft 15, connecting wheel 16, pulling seat 17 and outlet 18 are composed of structures. The main structure of the valve is: the electromagnet is connected with the upper cover 6, the upper cover 6 is fixed with the valve body through the connecting bolt 8, and the upper cover can play a sealing role. The mechanism of the internal traction mechanism is: the push rod 5 of the electromagnet is connected to the connection block 10, the pull plate 11 is hinged with the connection block 10 and the pull seat 17, and the pull seat 17 is fixed on the valve core 13, so that the electromagnet can be gua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com