Capacitive electromagnetic flow meter used for non full package flow measurement

An electromagnetic flowmeter and flow measurement technology, applied in the application of electromagnetic flowmeters to detect fluid flow, measure flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as sensitive distribution, corrosion, and easy pollution of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The patent embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

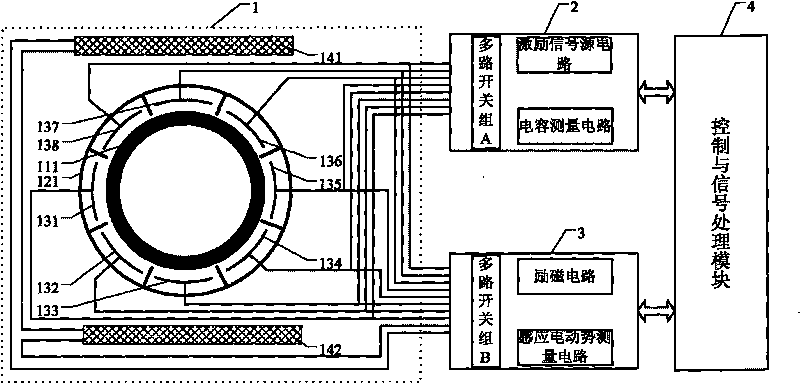

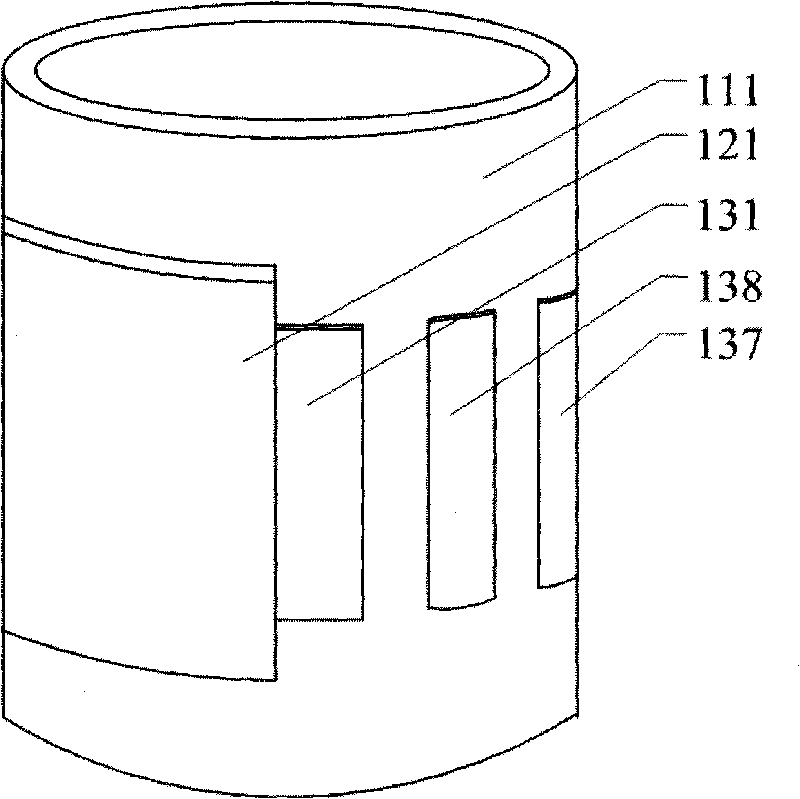

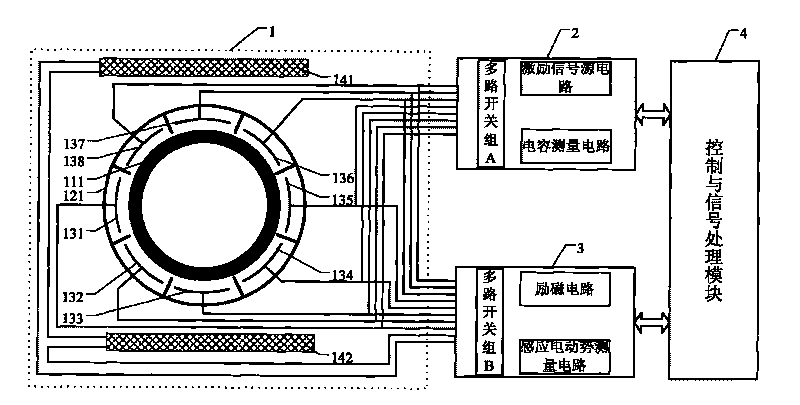

[0016] attached figure 1 It is a structural schematic diagram of a capacitive electromagnetic flowmeter that can be used for partial pipe flow measurement. The electromagnetic flow sensor 1 includes a measuring tube 111, electrodes 131 to 138, shielding electrodes 121, and excitation coils 141 and 142; the measuring tube is a circular tube structure, and its manufacturing material is insulating material; the electrodes 131 to 138 are rectangular metal sheets , evenly attached to the outside of the measuring tube 111, without direct contact with the fluid to be measured, wherein the central connection line of the electrode 131 and the electrode 135 is parallel to the horizontal plane and perpendicular to the central connection line of the coil; the shielding electrode 121 is located between the electrodes 131 to 138 On the outside, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com