Tail clamping and locking mechanism of low-frequency electric connector

A technology of electrical connectors and locking mechanisms, which is applied to parts, connections, circuits, etc. Diameter difference, anti-pull and other problems, to achieve good clamping effect, ensure electromagnetic compatibility, and high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

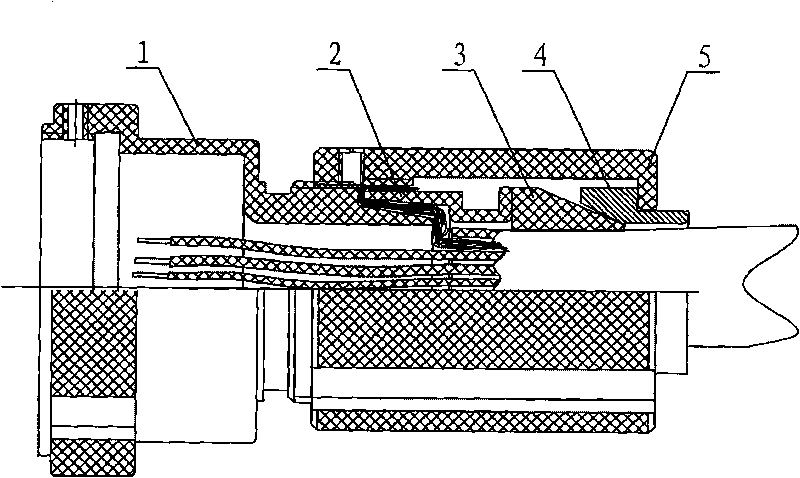

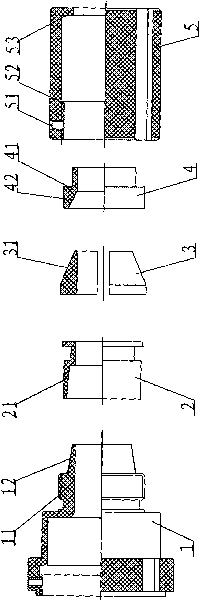

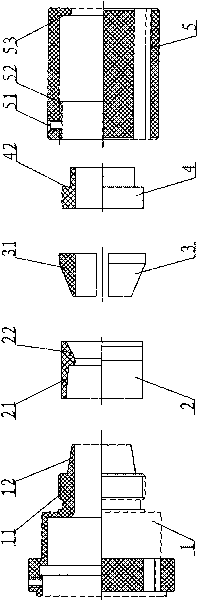

[0021] figure 1 , 2 In the first embodiment shown, a clamping and locking mechanism at the tail of a low-frequency electrical connector mainly includes a wire sheath 1 , a shielding sheath 2 , two clamping flaps 3 , a pressure ring 4 and a cable cover 5 . An outer conical surface 12 is provided on the tapered outer wall of the tail of the grommet 1, and the outer conical surface 12 is provided with an external thread 11. One end of the shielding sleeve 2 is provided with an inner conical hole 21 matching the outer conical surface 12, and the inner conical hole of the shielding sleeve 21 cooperates with the outer conical surface 12 of the wire sheath to press the cable shielding net, and the other end of the shielding sheath 2 abuts against one end face of the two clamping flaps 3, and the outer surface of the other end of the two clamping flaps 3 is a conical surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com