Factory three-dimensional seedling raising bedstead

A technology of planting seedlings and industrialization, applied in the application, cultivation, agriculture and other directions, can solve the problems of low production efficiency and low space utilization rate, and achieve the effect of improving production efficiency, reducing seedling cost and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

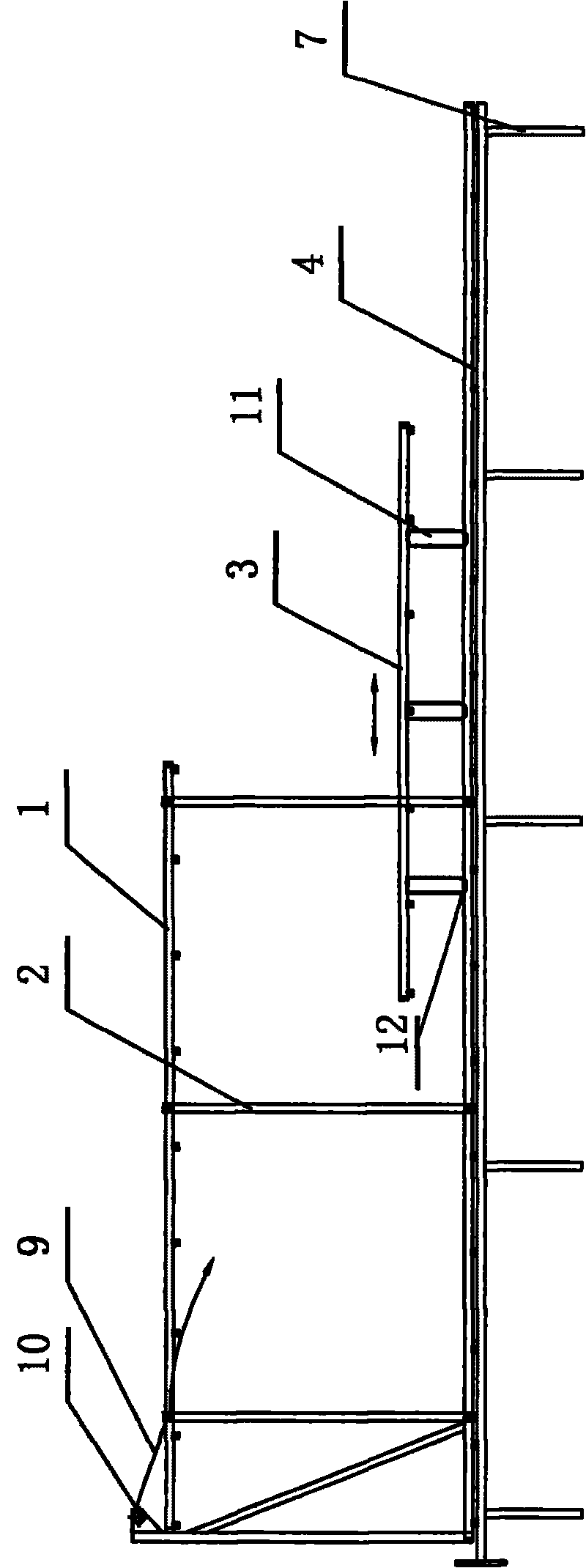

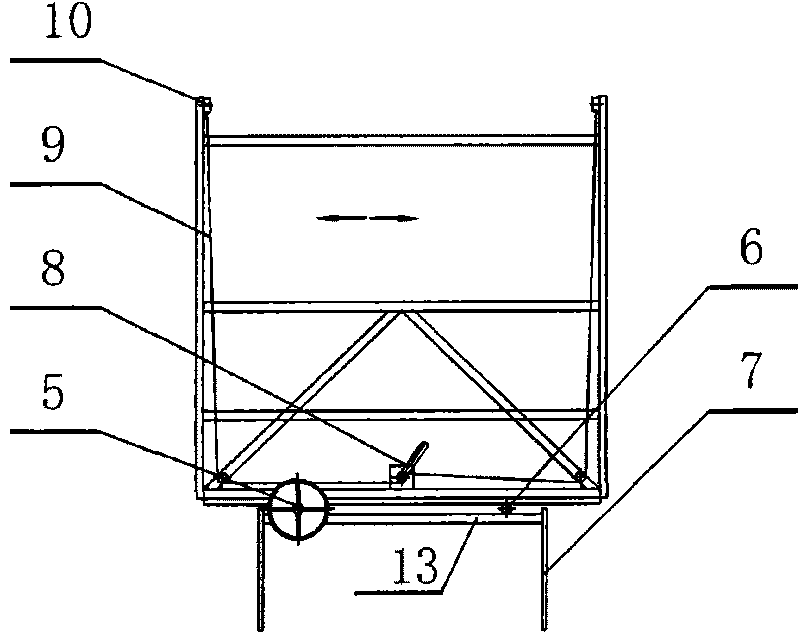

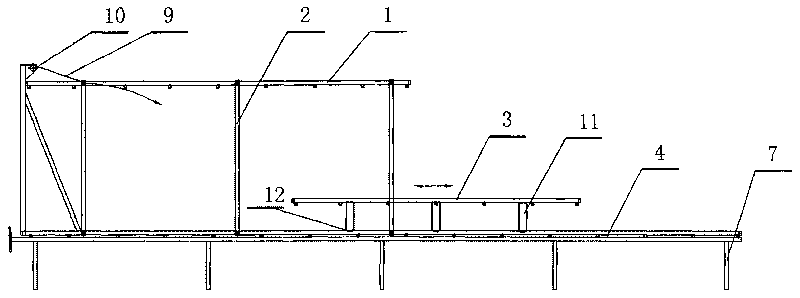

[0013] The industrial three-dimensional sports seedbed frame of the present invention comprises an upper bed frame 1, a middle layer bed frame 3 and a lower layer bed frame 4 from top to bottom, and the upper layer bed frame 1 is installed on the lower layer bed frame 4 through several upper layer bed frame brackets 2 , a pulley 10 is installed on the top of the upper bed frame bracket 2 at the front end, and then several upper bed frame brackets 2 and the lower bracket 4 are connected by shafts, and the lower bracket 4 is also provided with a ratchet pawl mechanism 8, a wire rope 9 one ends are wound on the ratchet pawl mechanism 8, and the other end passes through the pulley 10 and is fixed on the upper bed frame 1, like this, by adjusting the ratchet wheel pawl mechanism 8, the upper layer bed frame 1 just can realize lifting up and down.

[0014] The middle bed frame 3 is installed on the lower bed frame 4 through the middle bed frame bracket 11, and a roller 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com