Water-proof and damp-proof underground granary

A technology of underground granary and moisture-proof layer, applied in the field of underground granary, can solve the problems of waterproof and moisture-proof, low degree of mechanization, large floor space, etc., to increase the scope of application, reduce the difficulty of construction, and save construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following structural drawings and embodiments further illustrate the present invention.

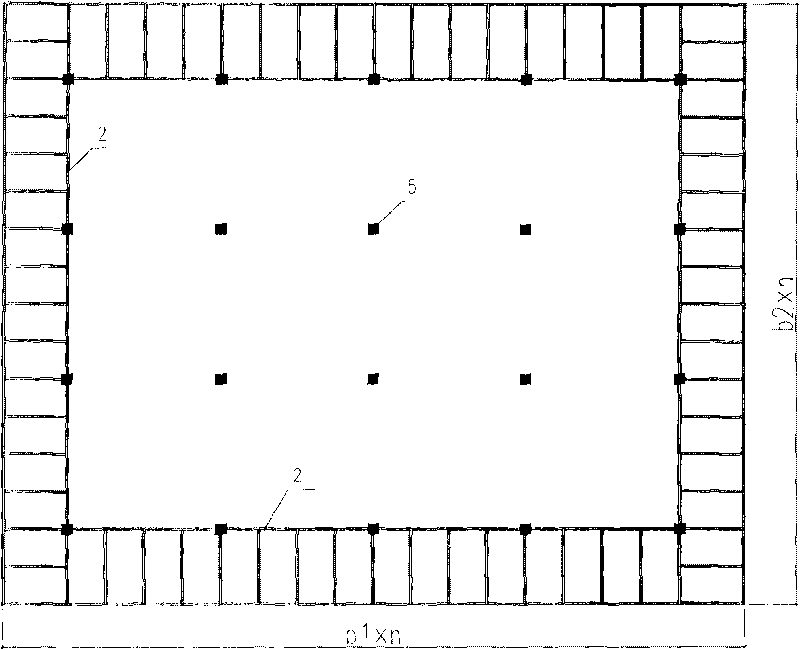

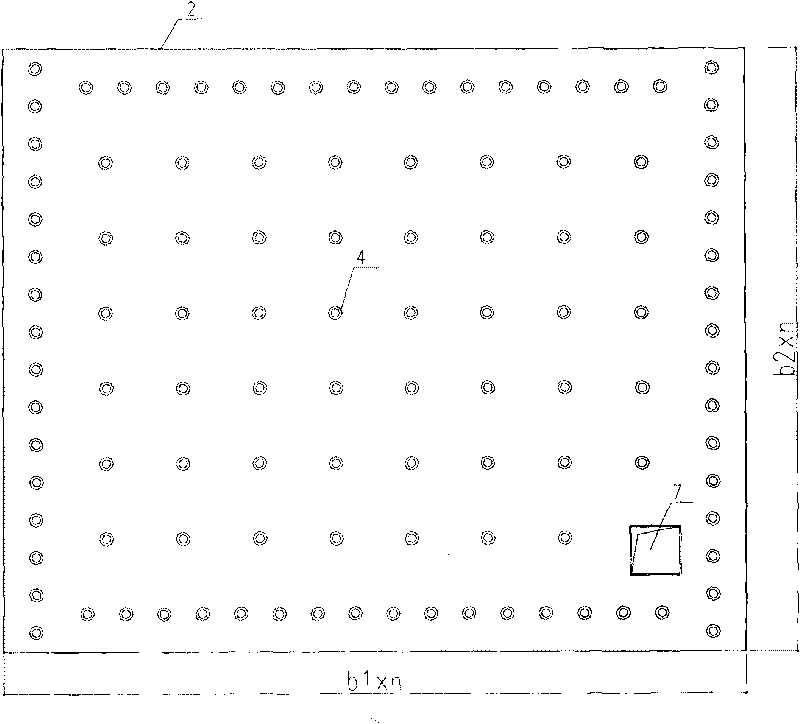

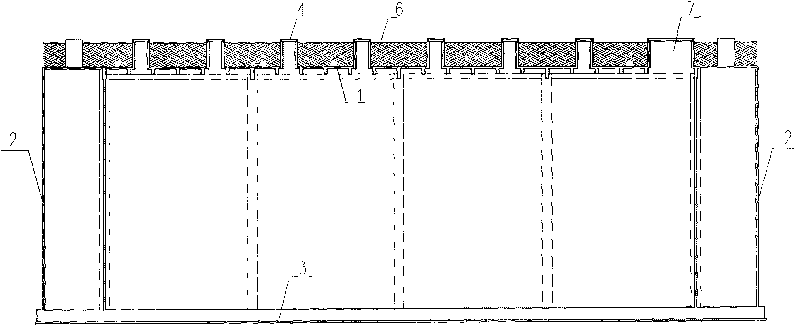

[0027] The present invention is a long 58 meters as shown in the accompanying drawing, the rectangular underground granary of wide 48 meters, comprises warehouse top 1, warehouse wall 2, warehouse bottom 3, and the long side of warehouse wall 2 is the rectangle of 3x5 meters by 16 side lengths The short side of the warehouse wall 2 is composed of 12 rectangular tubes with a side length of 3x5 meters. The top and bottom of the warehouse are supported by 20 columns 5. The top of the warehouse 1 is provided with a grain inlet and outlet 4. The roof of the warehouse 1 is a beam-slab structure. In this way, the roof of the warehouse 1 transmits the load to the secondary beam, and then from the secondary beam to the main beam. Pass to pillar 5 by main girder again. There is a 2-meter-thick covering soil 6 on the warehouse roof 1 top.

[0028] The warehouse roof 1 is used to support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com