Directional rzeppa universal joint

A universal joint and ball cage technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve the problems of motion trajectory interference, inconsistent force directions at contact points, and complex universal joint structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

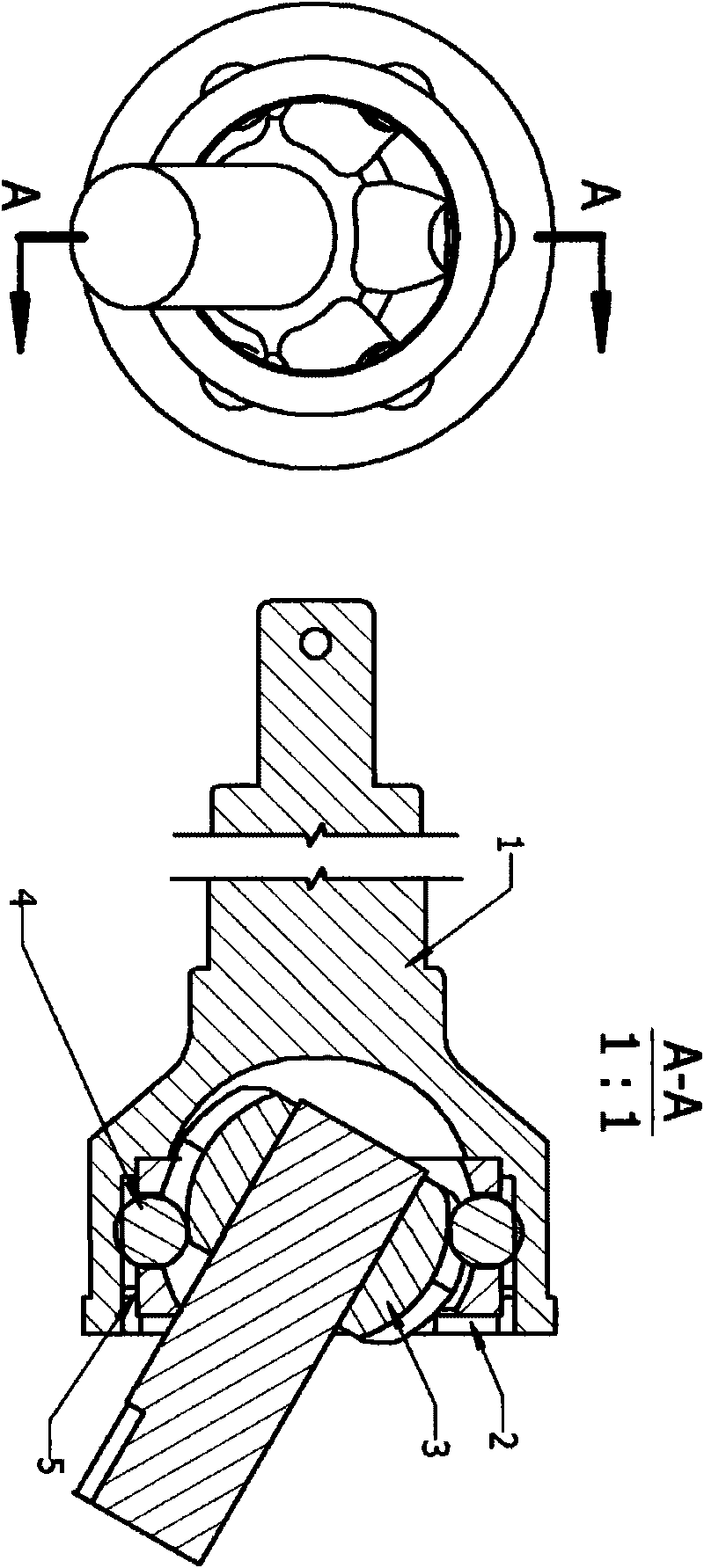

[0009] The first part: Orientation device, refer to the diagram to explain the structure;

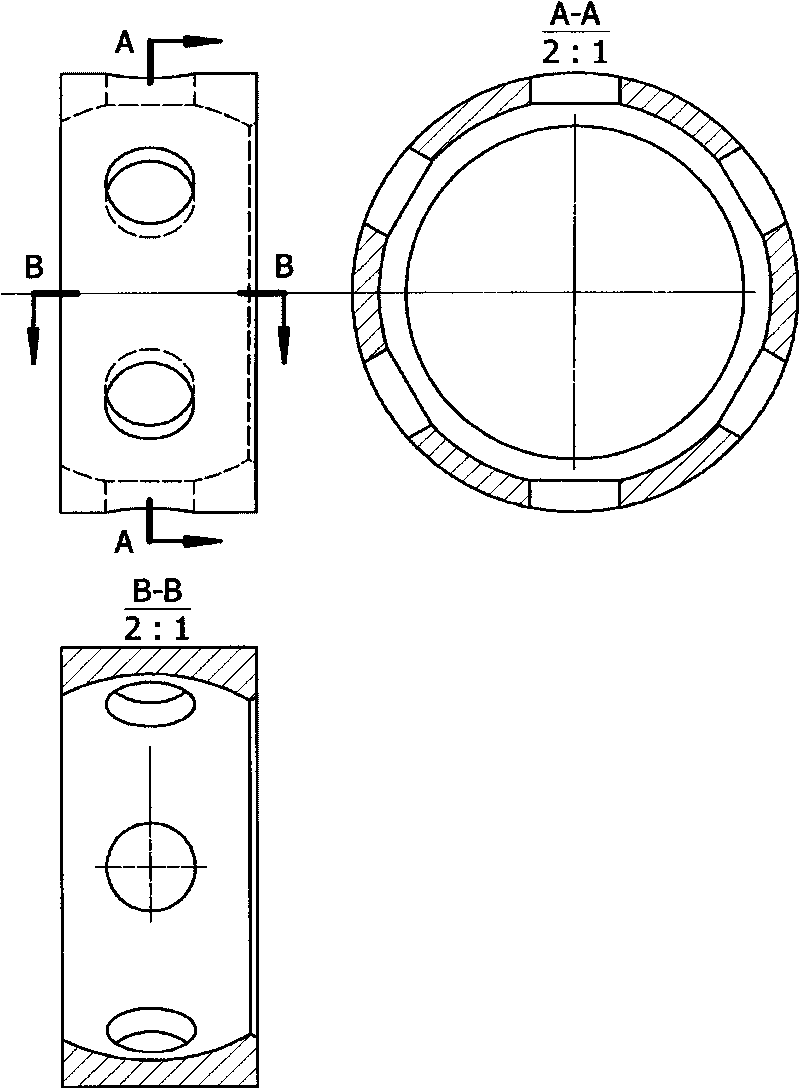

[0010] figure 1 Middle 1; Ball cage shell, 2; Cage, 3; Star wheel, 4; Steel ball, 5; Shaft card. The housing and the cage adopt a sliding fit. It can be seen from the figure that the cage is eccentric. The function of eccentricity is to allow the star wheel to fit into the cage and reserve a larger hole. Compared with the arc of the star wheel cage (see figure 2 ) is divided into two sections, one of which is transferred to the shell. The axial direction of the inner circle of the housing is provided with the same number of straight channels according to the number of steel balls to prevent slipping. When the cage and the star wheel are loaded into the spherical shell, the large end of the cage aperture faces inward, and the cage is positioned with a shaft card.

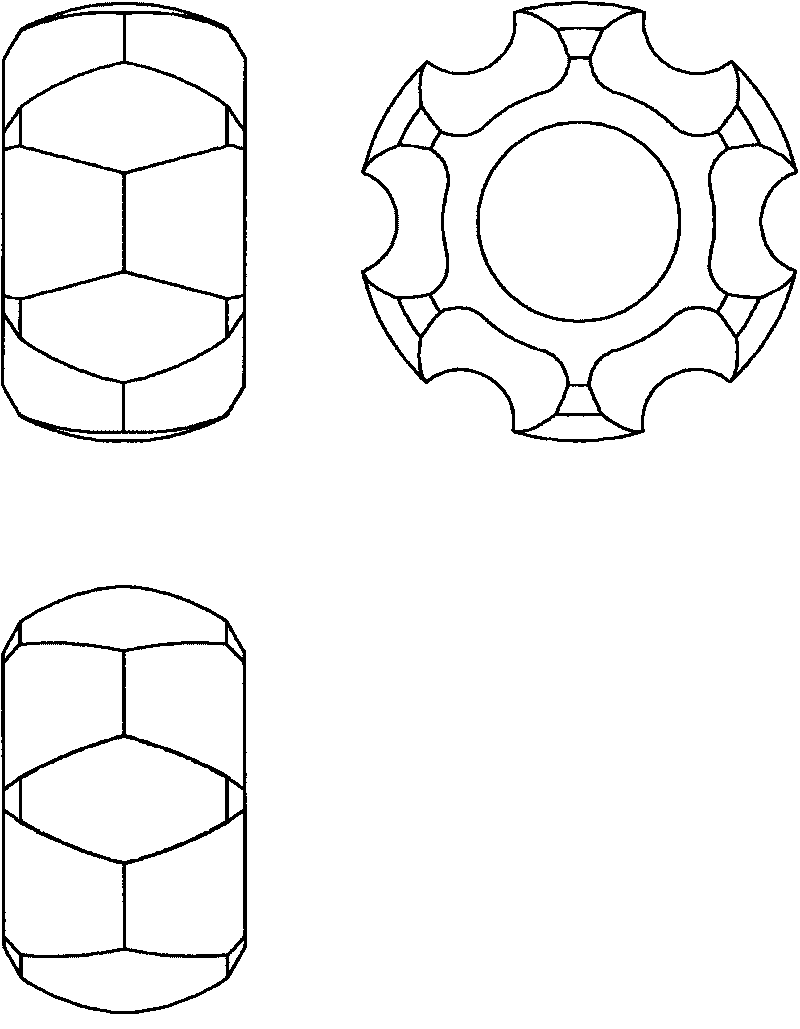

[0011] The second part; modification of star wheel, see appendix image 3 ;

[0012] The difficulty of X modification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com