Method for planning destination and cooperation disassembly of complex product supporting green design

A technology for complex products and planning, applied in computing, data processing applications, instruments, etc., to achieve the effect of overcoming combinatorial explosion, fast solution, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

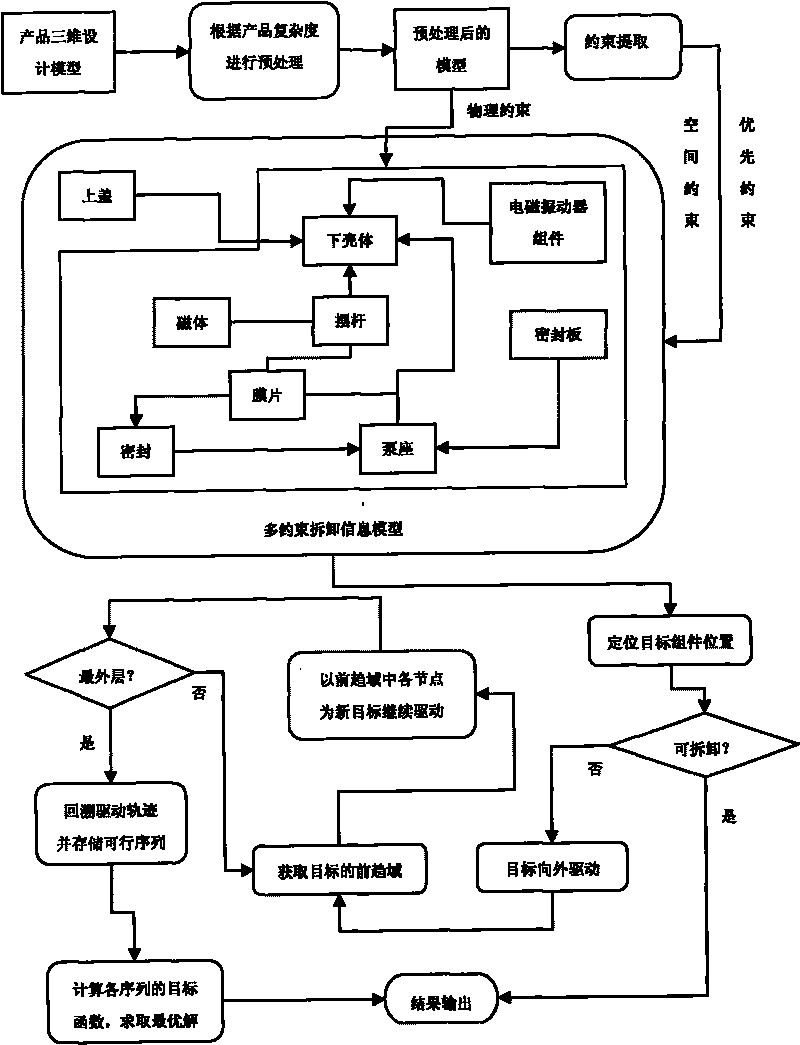

[0033] Such as figure 1 As shown in the figure, it is a general flow chart of the method for object disassembly planning of complex products supporting green design in the present invention.

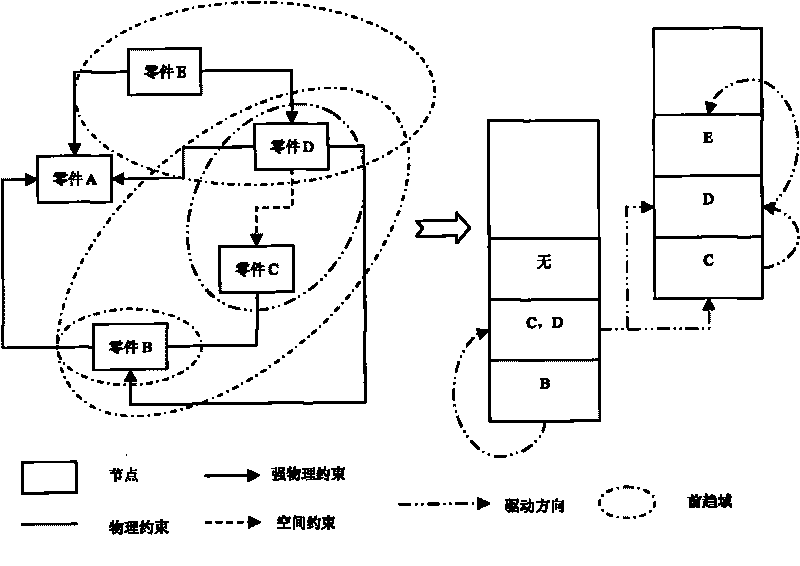

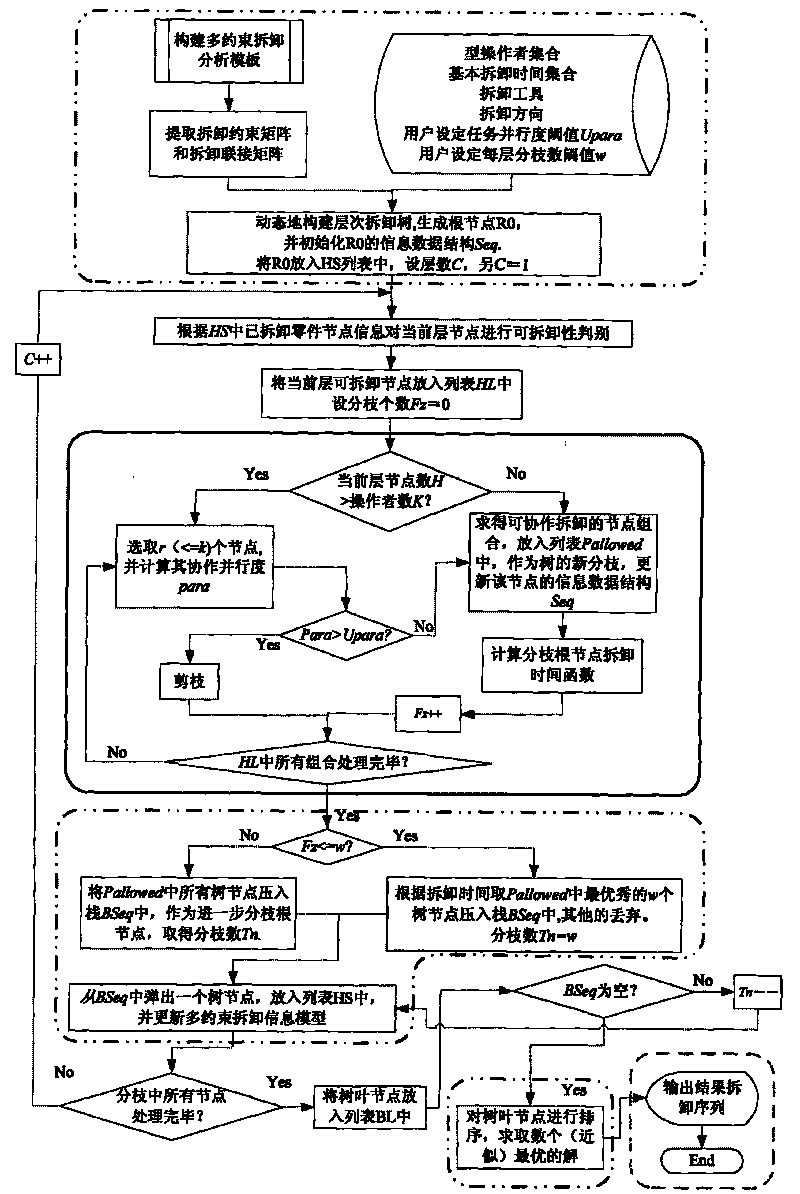

[0034] The complex product target disassembly planning system takes the product 3D design model as the research object. In the preprocessing stage, the minimum disassembly unit is determined according to the complexity of the model and the specific requirements and used as the node of the multi-constraint disassembly information model. Generally, the parts are used as nodes. When the product When it is more complicated, the sub-assembly is used as a coarse-grained disassembly unit, and then processed layer by layer, and fasteners and other connectors are put into the edge as constraint information. After the preprocessing is completed, the constraint information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com