Safety estimation method for an industrial special steel cable assembly

A safe and special technology, applied in the field of safety assessment of industrial special steel cable components, can solve the problems of serious time-consuming, difficult to meet engineering needs, large amount of calculation, etc., to achieve less time-consuming, reduce algorithm complexity, and evaluation accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

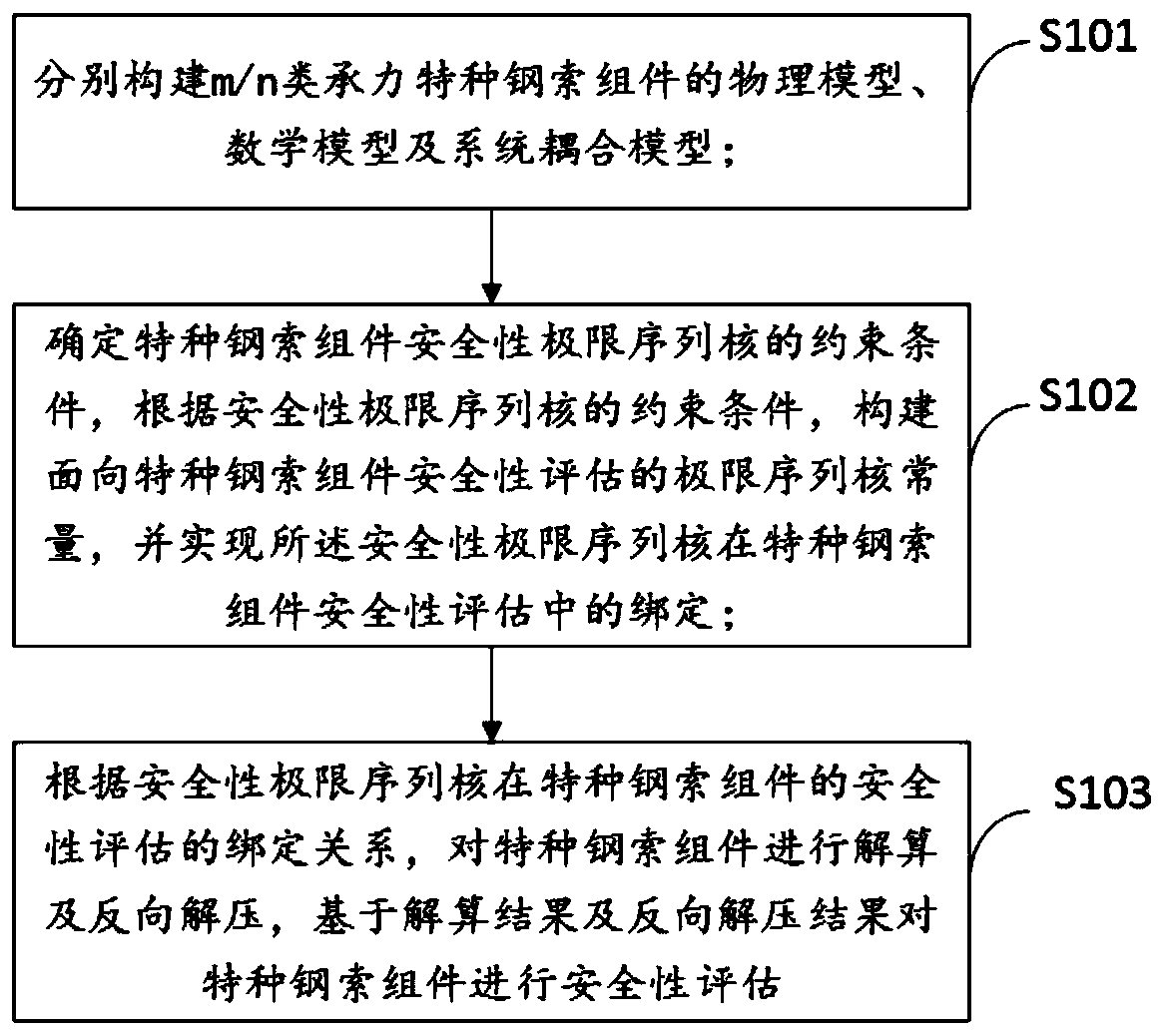

[0016] see figure 1 , a schematic flow chart of a method for evaluating the safety of an industrial special steel cable assembly provided in Embodiment 1 of the present invention, including:

[0017] S101. Constructing the physical model, mathematical model and system coupling model of the m / n type load-bearing special steel cable assembly respectively;

[0018] In the m / n type load-bearing special steel cable assembly, by the physical model of the special steel cable assembly, it is assumed that the special steel cable assembly is composed of n built-in strand units stacked, for a large number of steel cable assemblies (such as n> 100), the safety level of each strand unit i, 1≤i≤n, directly affects the safety level of the entire special steel cable assembly, and the general safety risk requirements of related projects are: steel cables are built into n strand units , at least m strand units should be kept within the acceptable safety risk range at all times.

[0019] Optio...

Embodiment 2

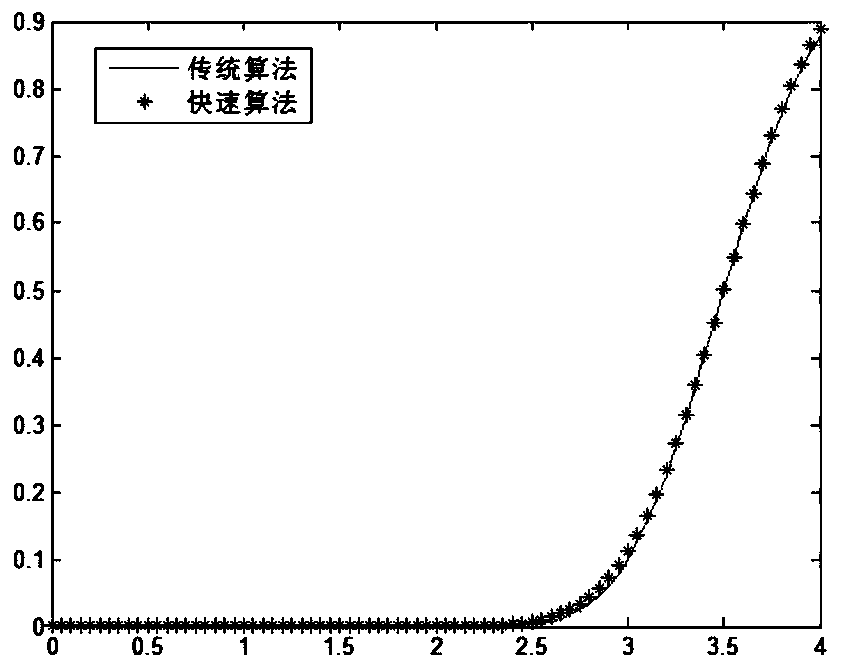

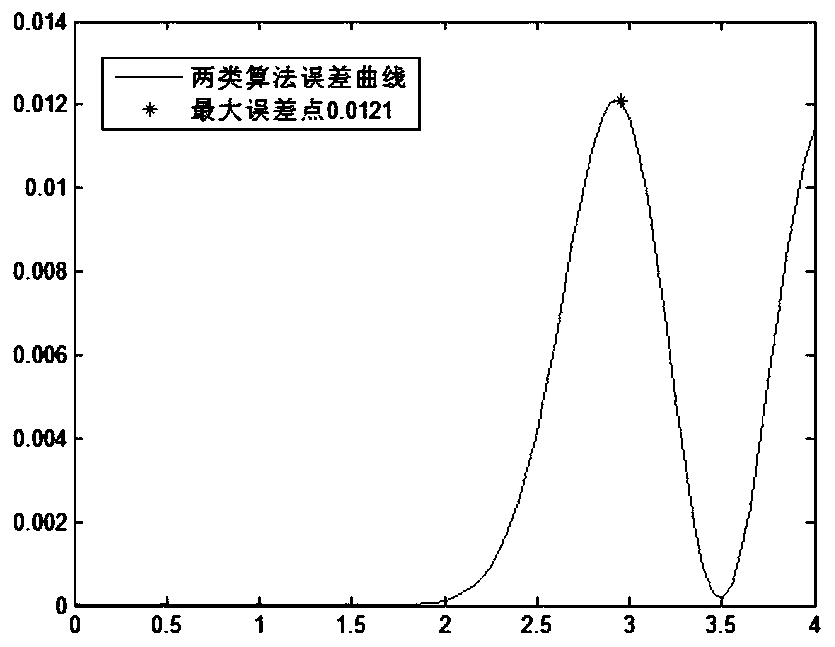

[0069] figure 2 , image 3 The schematic diagrams for comparing the risk amount of the limit sequence kernel algorithm and the traditional analysis algorithm provided by the embodiment of the present invention and the comparison diagram of the safety error are respectively. On the basis of the first embodiment, a specific example is used to perform the operation of safety assessment through the limit sequence kernel. The performance is described in detail:

[0070] Assuming n = 150, m = 75, λ = 0.2 / a, for m / n type special steel cable assemblies whose built-in strand element risk conforms to the homogeneous exponential distribution, the safety assessment is realized by using the traditional method and the limit sequence kernel respectively The performance analysis of these two methods:

[0071] When the traditional safety analysis algorithm is used to solve the m / n type load-bearing special steel cable assembly, its quantitative analysis expression is:

[0072]

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com