An Optimal Design Method for U-shaped Bellows Under High Pressure Externally

A technology for optimizing design and bellows, which is applied in computing, special data processing applications, instruments, etc., and can solve problems such as cumbersome bellows and errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Step 1: Select and confirm material data

[0077] The selected bellows material is stainless steel 00Cr17Ni14Mo2, and the stress-strain curve of the material is obtained.

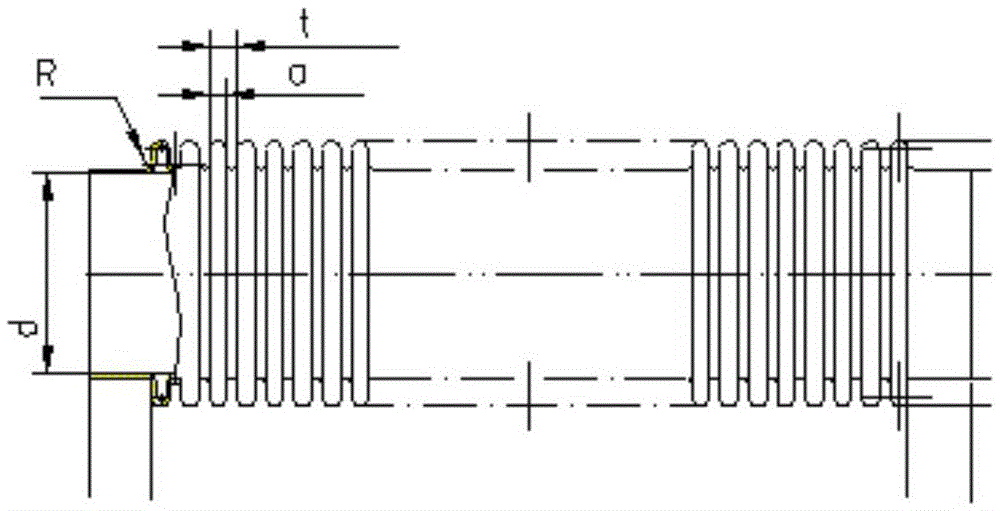

[0078] Step 2: Determine the range of the outer diameter of the bellows D and the range of the total length L

[0079] The outer diameter of the bellows is less than or equal to 32mm, and the total length is less than 100mm.

[0080] Step 3: Select the environmental conditions of the bellows

[0081] The maximum external pressure of the bellows is 5MPa, the axial stiffness is not more than 85N / mm, the critical pressure of plane instability is 5MPa, and the axial compression of the bellows is 12mm.

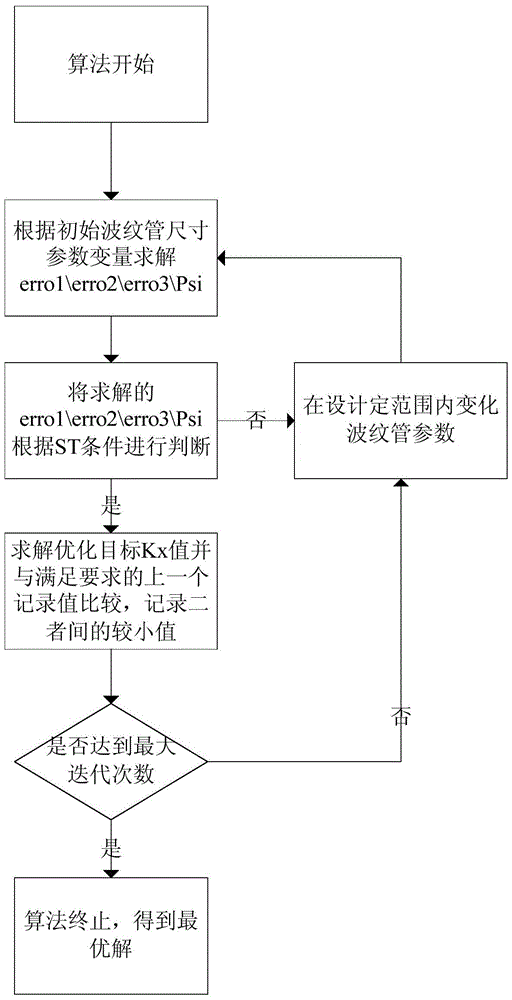

[0082] Step 4: Formulate an optimal design mathematical model

[0083] Set the initial size of the bellows as D=32mm, d=21mm, t=3.1mm, a=1.9mm, n=16, Z=2.

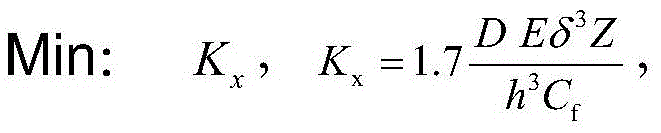

[0084] Min : K x , K x = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com