Floating water sealing coaxial electric connector

An electric connector and water-sealed technology, which is applied in the direction of conductive connection, connection, and two-part connection device, can solve problems such as difficult alignment of mating, difficult assembly and disassembly of waterproof rubber sleeves, poor impact resistance, etc., and achieve good resistance Impact performance, good water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

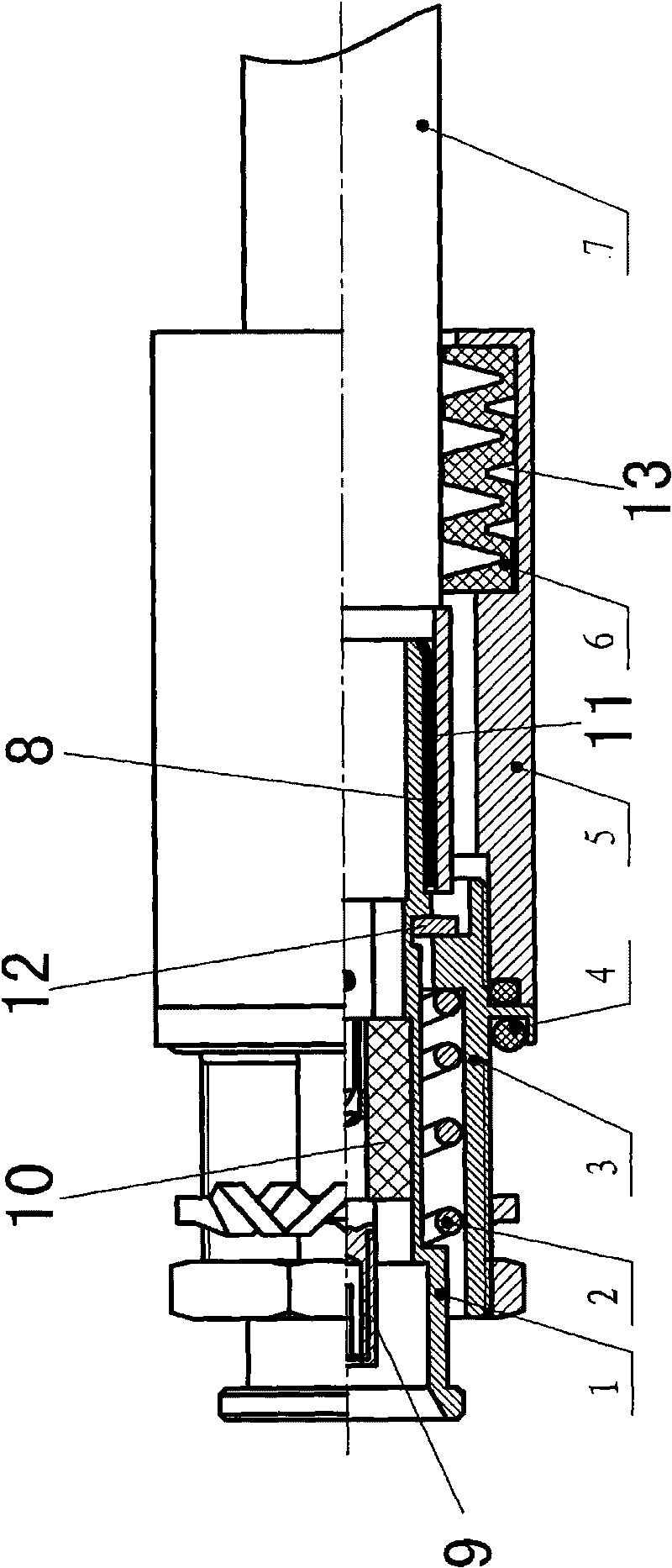

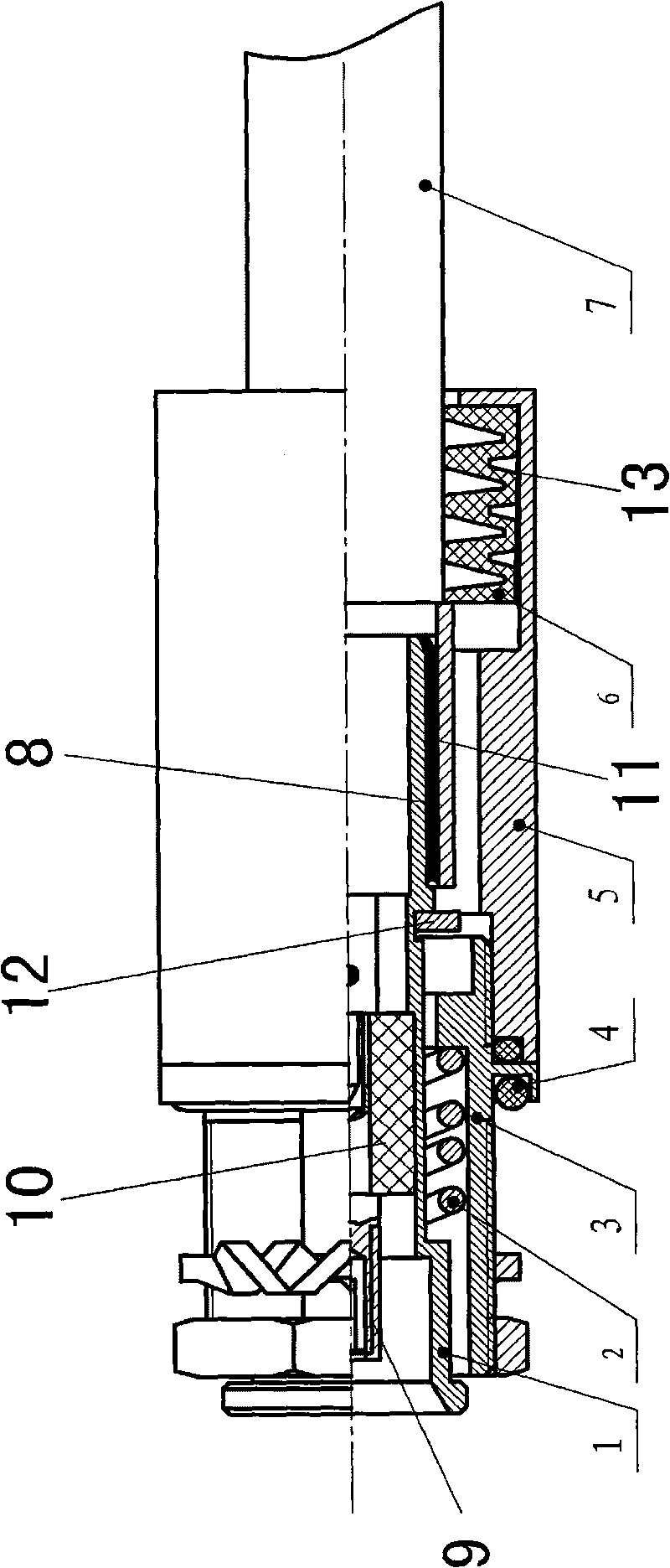

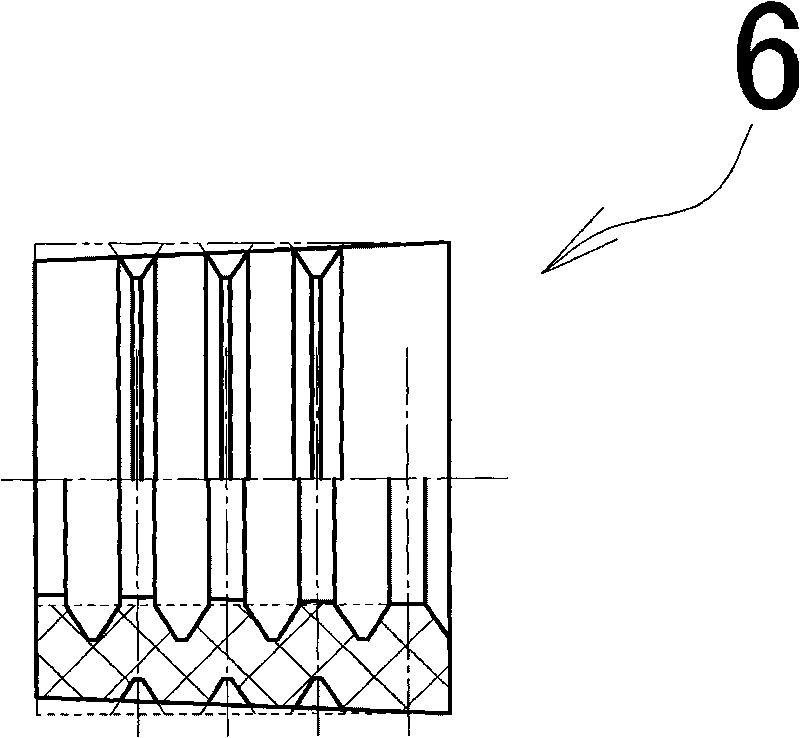

[0016] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the coaxial electrical connector of the present invention includes a floating housing 1 with a through hole inside, a sleeve-shaped insulator 10 is installed in the through hole inside the floating housing 1, and the inner hole of the insulator 10 is fixed. An inner conductor 9 is installed, and one end of the floating housing 1 is a plug-in terminal for mating with an adapter contact, and the other end of the floating housing 1 is a terminal and is mated and fixed in the metal compression sleeve 8, and the coaxial cable The central conductor and insulating layer of 7 pass through the rear end opening of the pressure sleeve 8 and enter the floating shell 1, and the metal braid 11 of the coaxial cable 7 is pressed tightly on the inner hole of the pressure sleeve 8 and the outer periphery of the floating shell 1 Between, to achieve conductive connection. A thin neck section is provided on the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com