Uncoiling method and system for guide rope of electric power of unmanned helicopter

A technology of unmanned helicopters and guide ropes, which is applied in the direction of motor vehicles, overhead lines/cable equipment, aircraft, etc., can solve the problems of difficult guide ropes, low requirements for ground conditions, and easy leakage of gas fuel, etc., to ensure a safe distance, The effect of simple ground support and low take-off and landing site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The method and system for unmanned helicopter power deployment guide rope of the present invention will be described in detail below with reference to the accompanying drawings.

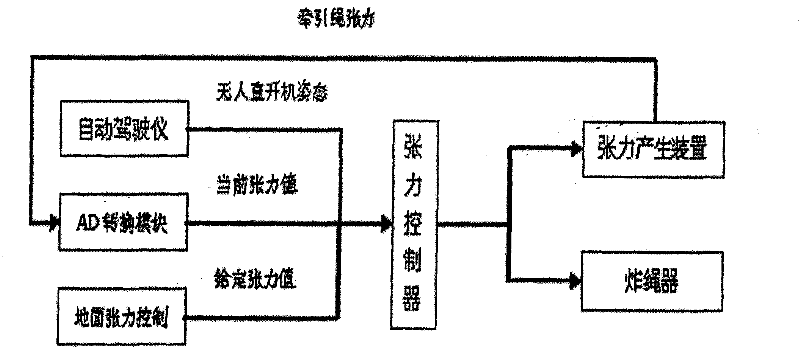

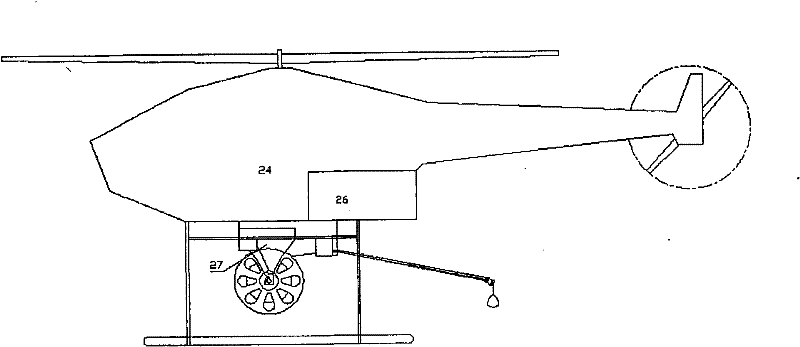

[0048] figure 1 The block diagram of the unmanned helicopter electric deployment guide rope system of the present invention; in the method of the technical solution of the present invention, the unmanned helicopter 24 deployment lead wire system is mainly composed of an airborne part and a ground part, and the airborne part includes: the unmanned helicopter 24. Autopilot 26, Pay-off tension controller 1, video auxiliary system, pay-off frame 27, emergency cut-off device, airborne radio and antenna; the ground part includes: ground station, mission controller, video monitor, power supply, radio and antenna.

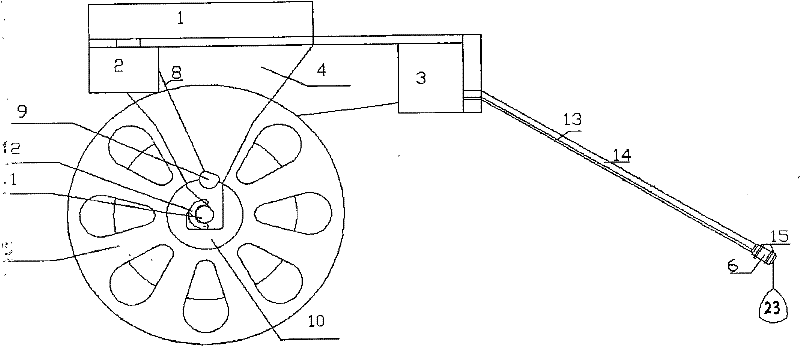

[0049] figure 2 Schematic diagram of unmanned helicopter mounting and pay-off rack, image 3 It is a schematic diagram of the structure of the pay-off frame. As shown in the figure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com