Filter bag collecting device for bag-type dusters

A technology of bag dust collector and collection device, which is applied in the direction of dust removal, dispersed particle filtration, chemical instruments and methods, etc. It can solve the problems of affecting the user's corporate image, prolonging the maintenance time, increasing maintenance costs, etc., and improving the maintenance work environment , enhance the corporate image and shorten the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

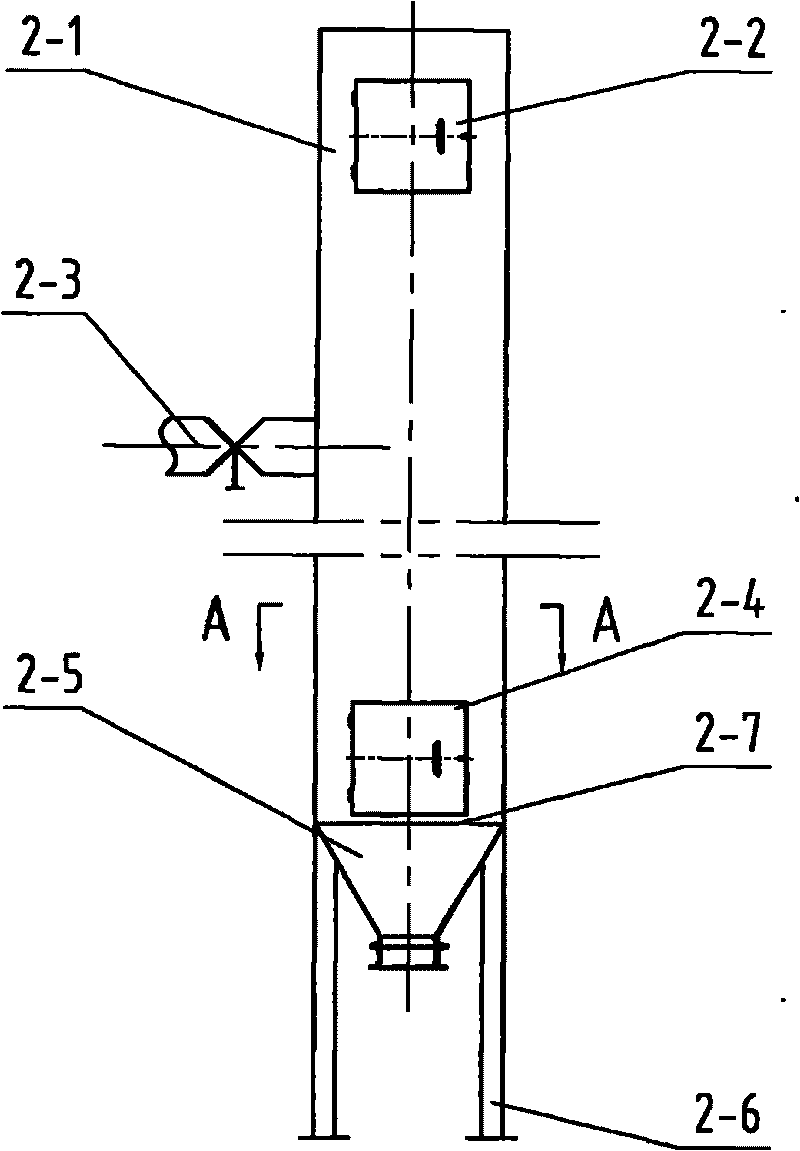

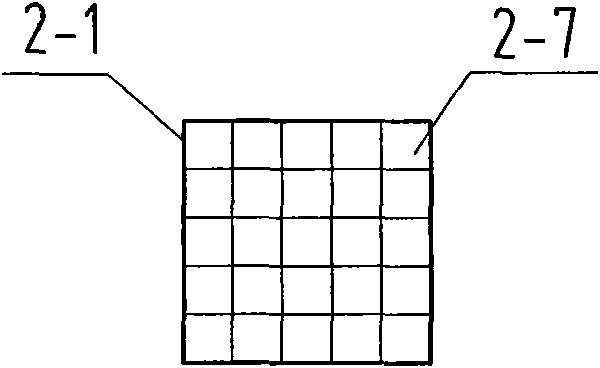

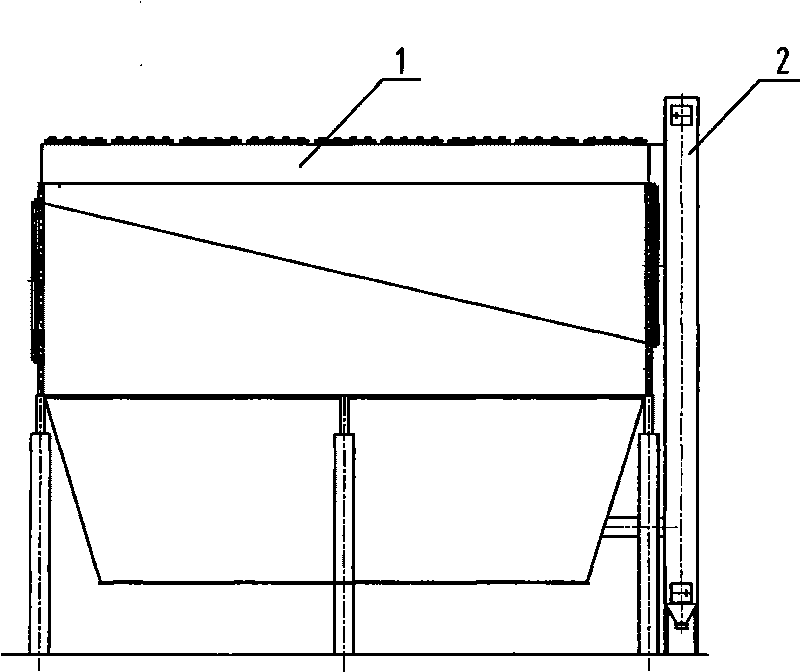

[0012] The present invention comprises rectangular pipeline 2-1, bag release door 2-2, dust discharge pipe 2-3, bag taking door 2-4, ash bucket 2-5, support frame 2-6, grille 2-7; The pipeline 2-1 is connected with the dust hopper 2-5 by welding, which is the main structure of the whole device, and is fixed on the foundation through the support frame 2-6, and is connected with the dust collector through the support frame arranged in the horizontal direction; At the upper part of the pipe 2-1, a bag release door 2-2 is set near the upper box inspection and bag replacement part of the bag filter 1, and a bag removal door 2-4 is set at the lower part of the rectangular pipe 2-1 and the upper part of the ash hopper 2-5; In order to prevent the filter bag from falling directly into the ash hopper 2-5, the upper part of the ash hopper 2-5 is provided with a grid 2-7 welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com