Vertical angle machine and method for manufacturing panel with edgefold

A vertical corner and panel technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of complex processing steps, low production efficiency, rough surface of the welded part of the product corner, etc., to achieve good surface quality and high processing efficiency High, the effect of eliminating the corner cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

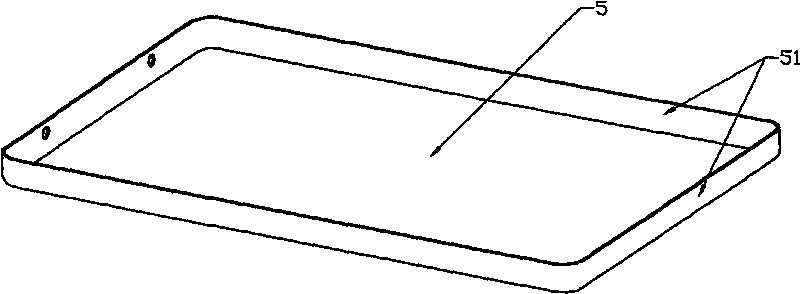

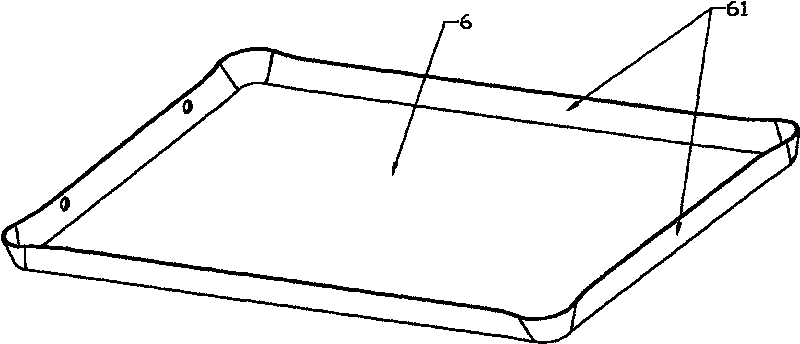

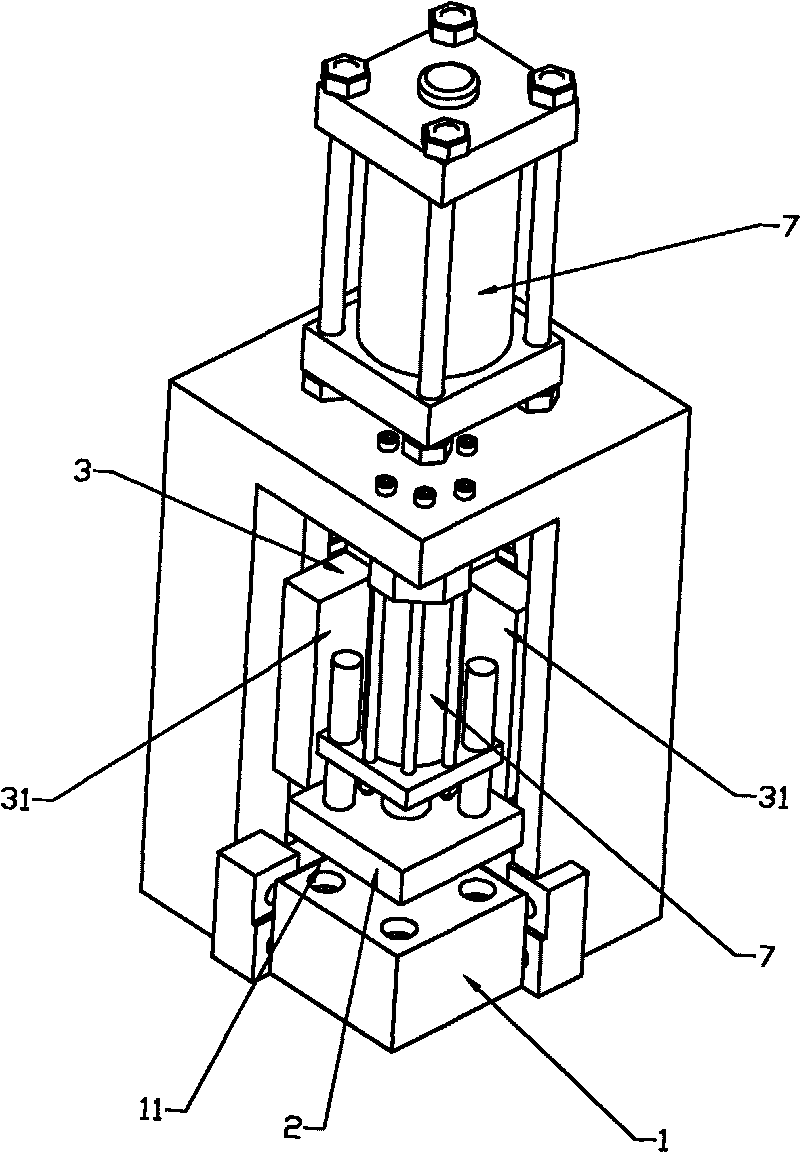

[0019] Such as Figure 3-9 As shown, the vertical angle machine of the present invention includes a lower template 1 arranged horizontally, the lower template has a right-angled working corner, and the working corner is formed by the intersection of two mutually perpendicular working edges 11; above the lower template An upper template 2 that can move up and down parallel to the lower template is provided; a stretching die 3 that can move up and down is arranged above the outer side of the working corner of the lower template, and the stretching die is composed of two vertically arranged The side plates 31 are composed of two side plates that are perpendicular to each other and intersect each other. The horizontal distance between the two side plates 31 and the two working sides 11 of the lower template is adapted to the thickness of the material to be processed; it is located below the outer side of the working corner of the lower template It also has a shearing die 4 that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com