Double universal joint consisting flexible knuckles

A technology of double universal joints and flexible joints, applied in the field of application, can solve the problems that cannot meet the requirements of multi-dimensional excitation table without gaps, structural gaps, and lack of flexible joint functions, etc., and achieve simple structure, flexible rotation, and compact structure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

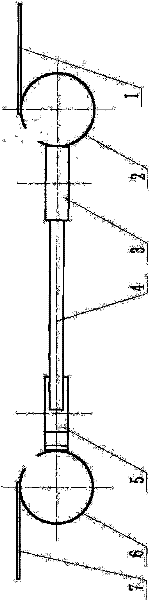

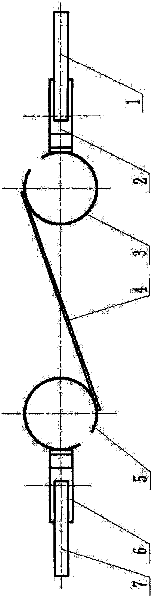

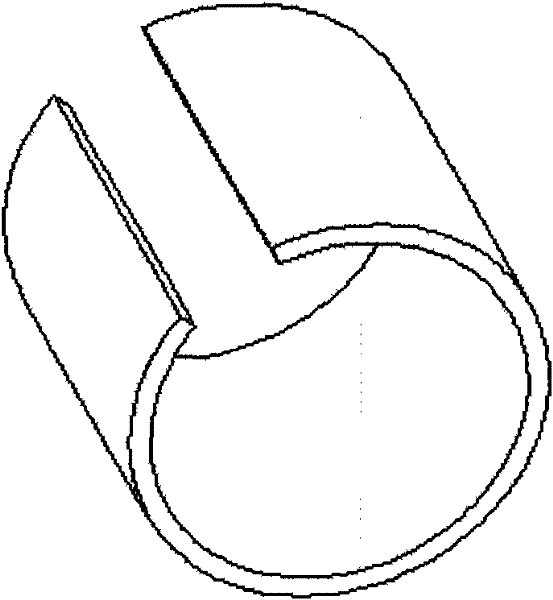

[0022] A double universal joint composed of double universal flexible joints is composed of flexible rotating pair 1, flexible rotating pair 2, flexible rotating pair 3, flexible rotating pair 4, 6, connecting plate 1, connecting plate 2, 4, connecting Plate III consists of 7. Flexible rotary pair one 2, flexible rotary pair two 3, flexible rotary pair three 5, flexible rotary pair four 6 are to have circular arc-shaped notch cylinder. Flexible rotary pair 1 2 and flexible rotary pair 2 3 are axially vertically connected, and flexible rotary pair 3 5 and flexible rotary pair 4 6 are axially vertically connected. The connecting plate one 1 is connected with the flexible rotating pair one 2 and is tangent. The second flexible revolving pair 3 and the third flexible revolving pair 5 are connected through the second connecting plate 4, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com