Vibration damper

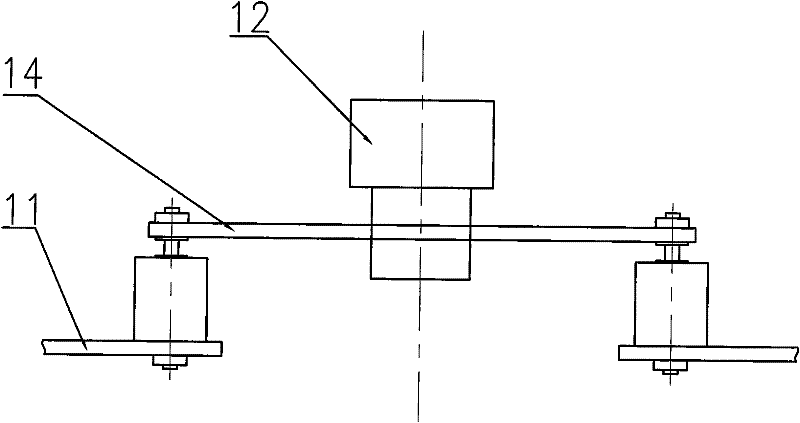

A technology of shock absorbers and rubber shock absorbers, which is applied in the direction of gas shock absorbers, etc., can solve the problems of engine failure, easy elastic fatigue of spring 13, poor shock absorption effect, etc., and achieve good shock absorption effect and long service life , enhance the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

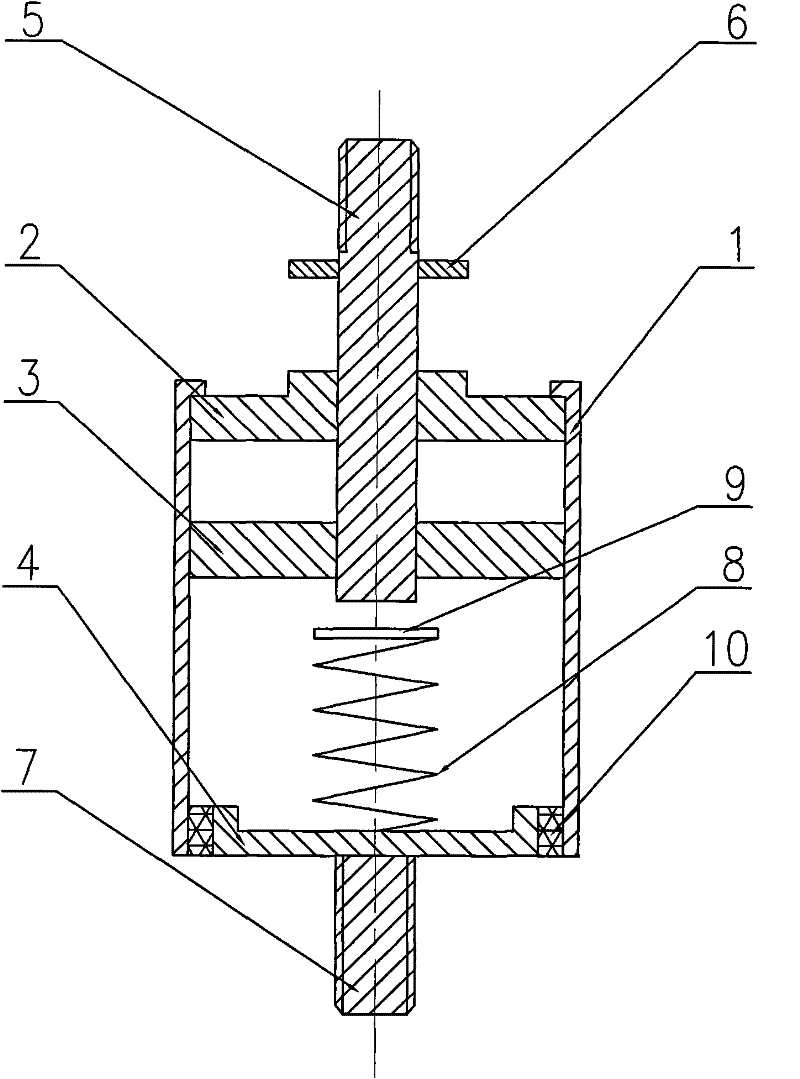

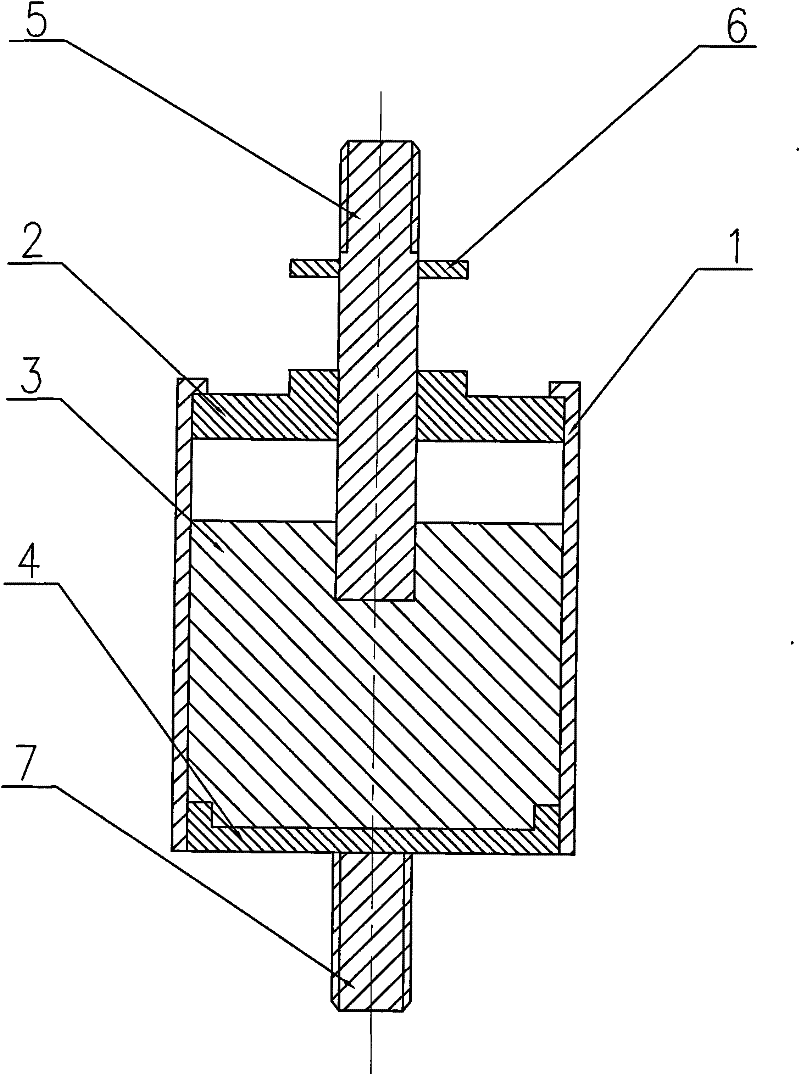

[0019] see figure 1 , is a schematic structural diagram of Embodiment 1 of the present invention. The shock absorber is mainly composed of a cylinder body 1, a guide plate 2, a rubber shock absorbing part 3, a bottom plate 4 and a screw rod 7, wherein the cylinder body 1, the guide plate 2 and the bottom plate 4 are metal parts, and the upper and lower ends of the cylinder body 1 are respectively The guide plate 2 and the bottom plate 4 are welded or riveted, and a rubber shock absorbing part 3 is bonded to the middle and upper part of the cylinder body 1. The rubber shock absorbing part 3 is a rubber diaphragm, and the material of the rubber diaphragm is rubber or rubber plastic. Neoprene or butyl rubber is preferred. The tensile strength of the rubber diaphragm is 200-630N / mm, the elongation at break is 400-700%, and the flexing resistance is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com