Oil-cylinder applied force load-balancing buffer mechanism

A cushioning mechanism and force technology, applied in grain processing, etc., can solve the problems of no cushioning, uneven force, etc., and achieve the effects of reducing direct impact, ensuring running performance, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following non-limiting examples illustrate the invention.

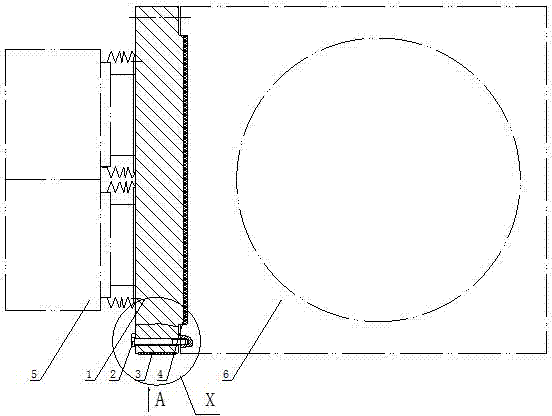

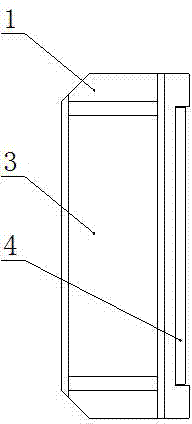

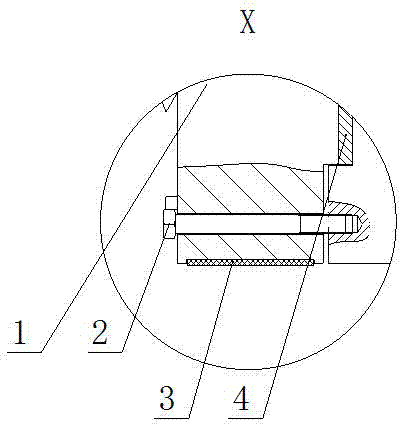

[0020] Such as figure 1 , 2 As shown in and 3, an oil cylinder force equalizing buffer mechanism includes an equalizing plate 1 arranged in parallel between the movable roller bearing housing 6 and the oil cylinder 5, and an anti-friction plate 3, which is arranged on the equalizing plate As shown in this embodiment, the lower end of 1 is in contact with the frame guide rail plate, and a friction-reducing plate 3 is arranged between two parallel convex strips at the lower end of the equalizing plate 1 . An elastic support plate is also provided between the equalizing plate 1 and the bearing seat 6, which can play the role of elastic support and absorb shocks and can be plate-shaped objects of various materials suitable for the working environment of the equipment. As shown in this embodiment, the elastic support The plate is preferably a rubber plate 4 . The equalizing plate 1 and the bearing seat 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com