Connecting structure of tubular fender

A connection structure, tubular technology, applied in the direction of ships, ship cleaning devices, hulls, etc., can solve the problems of partial damage to the hull and potential safety hazards, and achieve the effect of avoiding rigid connections and reducing the possibility of damage to the hull.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

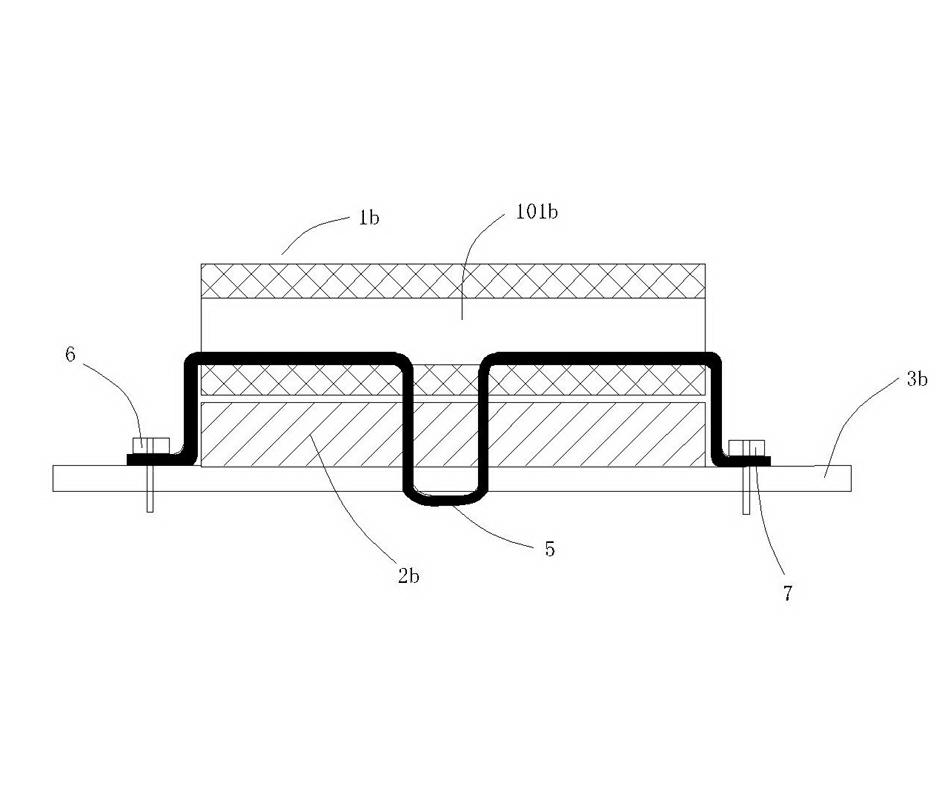

[0022] Such as image 3 In the first embodiment shown, the rope 5 is a whole section, and at least one position is constrained on the hull 3b. The specific structure is: the two ends of the rope 5 are tightened and fixed on the hull 3b, such as image 3 As shown in the fixed points 6 and 7 in the figure, the rope 5 passes through the tube wall of the tubular fender 1b, the buffer seat 2b and the hull 3b in a certain part in the middle of the tube cavity 101b, and passes through another position at a distance from the inner side of the hull 2b. Back in the lumen 101b, a short section of rope inside the hull 3b can be used to form the hull's restraint to the tubular fender 1b. What is shown in the figure is only a detour at one position. Of course, it can be understood that when the fender is longer, multiple such structures can be arranged at intervals along the length direction.

[0023] Such as Figure 4 In the second embodiment shown, the rope 5 is segmented, that is, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com