Suspension structure for serpentine tube panel

A technology of suspension structure and serpentine tube, which is applied in the direction of boiler support/positioning device, etc., can solve the problems that the expansion cannot be effectively released and the cost of header 1 is high, and achieve the effects of easy maintenance, simple structure and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

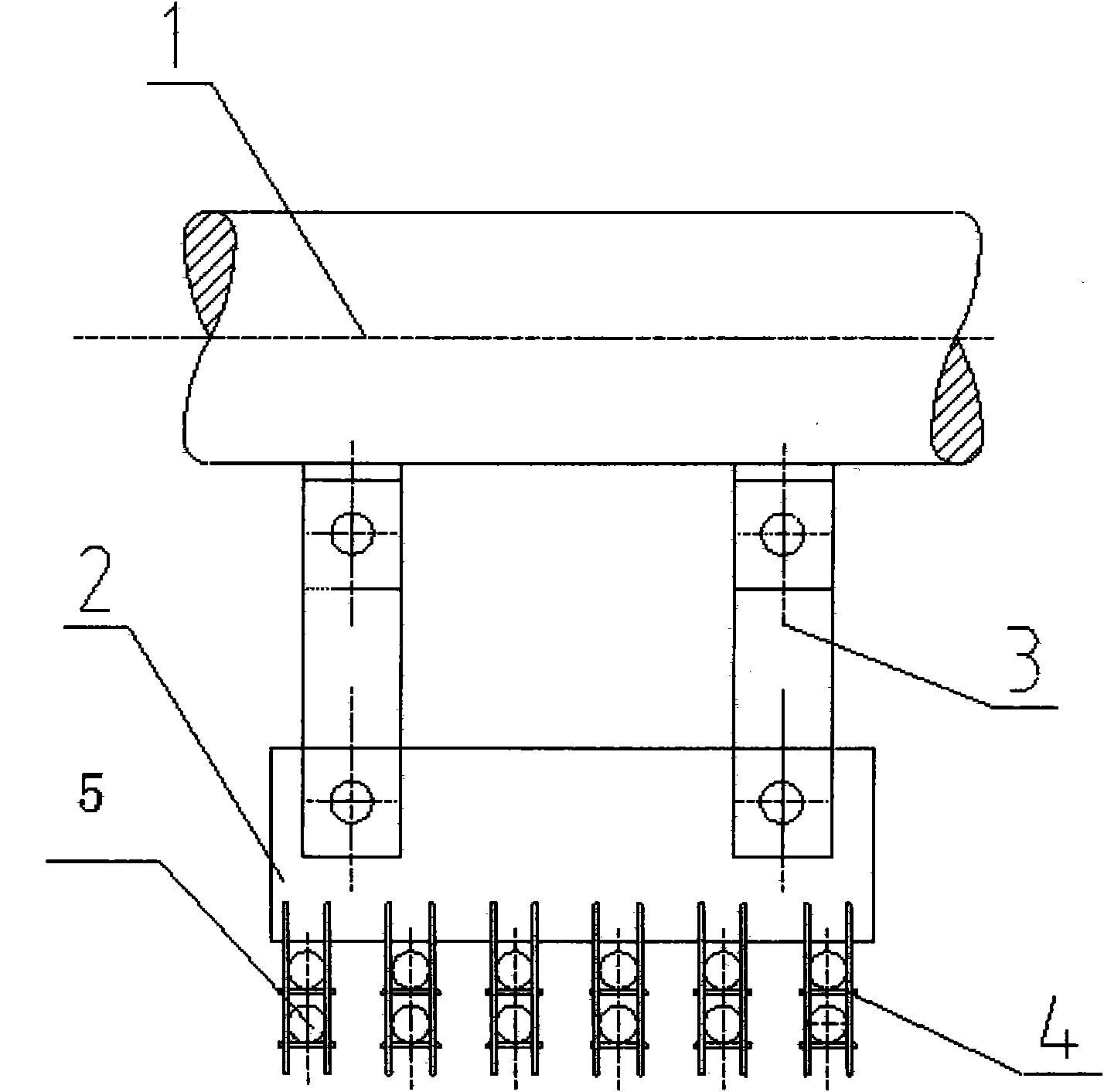

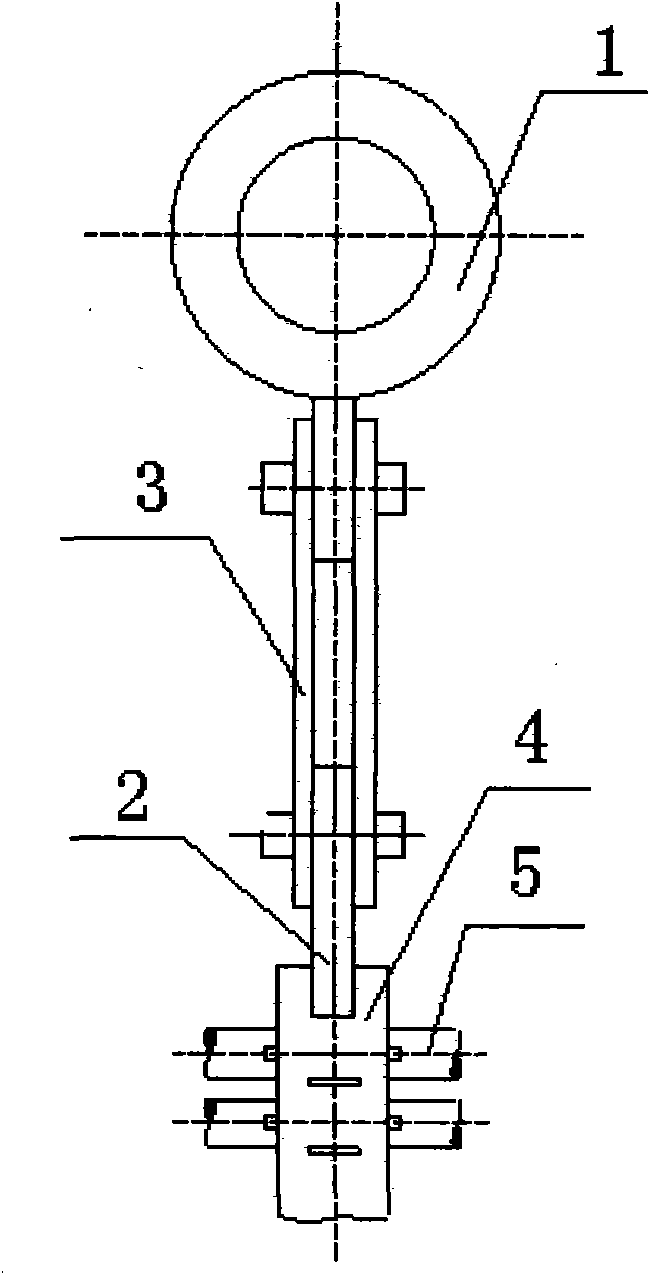

[0014] Such as image 3 and Figure 4 As shown, a suspension structure for a serpentine tube panel provided by the present invention includes a tube clamp 4, a serpentine tube panel 5 passes through the tube clamp 4, and a return-shaped steel plate 6 is provided on the top of the tube clamp 4, The back-shaped steel plate 6 runs through the steel beam 7, and its end is arranged outside the steel beam 7, and angle steel 8 is welded on both sides of the end of the back-shaped steel plate 6, and the angle steel 8 is placed on the steel beam 7, and on the steel beam 7 and the back The corresponding place of the through hole on the shaped steel plate 6 has a hole 9. A reinforcing rib is provided on the angle steel 8 .

[0015] In the present invention, the load-bearing element is changed from the header to the steel beam 7. First, it can be used in the rear smoke shaft where the intermediate header is inconvenient to arrange, and the layout scheme is more flexible; secondly, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com